-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Led . 06, 2025 19:04 Back to list

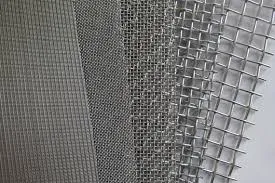

iron welded wire mesh

Iron wire mesh, a versatile product widely used across various sectors, embodies a synergy of practicality and engineering expertise. Its functionality extends from simple domestic applications to intricate industrial utility, offering a balance of durability and flexibility that few materials can match. As a seasoned expert in materials engineering, I've had the privilege of working with iron wire mesh in numerous projects, each time unlocking new dimensions of its capabilities.

The practicality of iron wire mesh lies in its construction – a network of interwoven wires that create a robust barrier capable of withstanding significant stress. This construction makes it an ideal choice for environments demanding resilience and stability. In agricultural settings, for instance, iron wire mesh acts as a reliable fencing solution, adept at keeping livestock secure. Its weather-resistant properties ensure that it endures the elements, reducing maintenance requirements and offering a sustainable solution to farmers worldwide.

Beyond the basics, the adaptability of iron wire mesh caters to a myriad of applications. In construction, it serves as a reinforcing agent in concrete work, enhancing structural integrity. Here, it not only buttresses the strength of construction materials but does so with an efficiency that speaks volumes about its engineering finesse. The ability of iron wire mesh to effectively distribute stress across its lattice structure lends an air of credibility to its use in safety-centric applications.

In industrial contexts, the mesh's ventilation and filtration capabilities lend themselves to processes requiring a careful balance of airflow and security. The spacing in the mesh permits optimal air passage while maintaining a formidable barrier against particulate matter. Industries dealing with food processing, chemical manufacturing, and even artisanal crafts have embraced iron wire mesh for its dual functionality, reinforcing its status as a staple material in their operational frameworks.

iron wire mesh

It's crucial to understand that the technological progression surrounding the manufacture of iron wire mesh has not stalled. Modern-day production techniques incorporate advanced galvanization processes, significantly enhancing the mesh's anti-corrosive properties. This evolution augments its already formidable lifespan, positioning iron wire mesh as a cost-effective solution in long-term projects. This longevity, paired with its inherent strength, reinforces its standing as a material of choice in economically driven projects.

From a sustainability perspective, iron wire mesh supports recycling processes, adding an eco-friendly dimension to its repertoire. As industries pivot towards sustainable practices, the ability to recycle and repurpose iron wire mesh aligns with global environmental goals, bolstering its appeal on ecological grounds. This commitment to sustainability further ingrains it as a trustworthy material in the eyes of environmentally-conscious consumers.

In conclusion, iron wire mesh stands as a testament to innovation and utility in material science. Its diverse applications, reinforced by advancements in manufacturing and sustainability, continue to meet the ever-evolving demands of industries worldwide. As a professional deeply entrenched in materials research, I can attest to its unmatched adaptability and resourcefulness, qualities that propel it to the forefront of material choices for contemporary and future challenges.

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025