-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Led . 29, 2025 03:23 Back to list

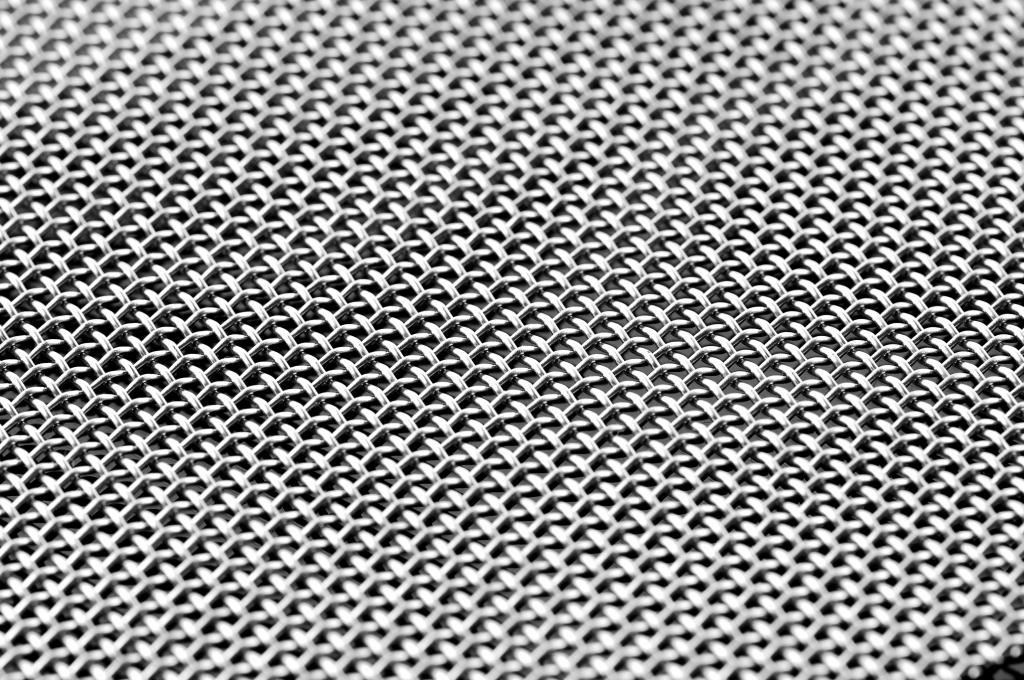

stainless steel wire mesh

Low carbon steel wire stands as a quintessential material in numerous industrial and construction applications, celebrated for its versatility, affordability, and eco-friendliness. It serves as a backbone in industries ranging from manufacturing to construction, owing much of its prowess to both its intrinsic properties and sustainable production processes. This makes it not just a staple in production but also a subject of interest among professionals aiming for a balance of cost-efficiency and environmental responsibility.

Authoritativeness plays a key role for manufacturers and suppliers of low carbon steel wire. Recognized bodies and materials certifiers stand behind the quality claims, reinforcing trust among end-users. Specific industry standards and certifications can be referenced to assure clients of the material's compliance with performance and safety benchmarks. Publications and case studies featuring the successful deployment of low carbon steel wire in pioneering projects further cement its reputation as a reliable material standard. In real-world applications, case studies abound where low carbon steel wire has outperformed other options. A notable example involves its use in automotive manufacturing. Here, engineers prioritize materials that offer strength without sacrificing the flexibility necessary for forming complex geometries. Low carbon steel wire meets these criteria, resulting in increased adoption for the fabrication of vehicle frames and safety components. Feedback from these deployments often notes the reduction in material waste and cost savings during the production cycle. These concrete experiences from trusted industry voices underscore the intrinsic value that this material offers. Moreover, the bonding characteristic of low carbon steel wire elevates its trustworthiness among users. Its consistency in performance reduces the likelihood of failure under stress, ensuring reliability in structural applications. This trust is further amplified by empirical evidence collected over years of use, which consistently indicates its superiority in durability compared to higher-carbon alternatives, particularly in applications subjected to continuous load or impact. In conclusion, low carbon steel wire maintains its standing through a blend of cost-effectiveness, environmental compatibility, and practical utility. These properties, supported by extensive hands-on experience and professional endorsements, make it a material that builders, engineers, and architects turn to repeatedly. As industries advance and emphasize sustainable practices, the role of materials like low carbon steel wire becomes even more pivotal, promising continued relevance and application across various sectors.

Authoritativeness plays a key role for manufacturers and suppliers of low carbon steel wire. Recognized bodies and materials certifiers stand behind the quality claims, reinforcing trust among end-users. Specific industry standards and certifications can be referenced to assure clients of the material's compliance with performance and safety benchmarks. Publications and case studies featuring the successful deployment of low carbon steel wire in pioneering projects further cement its reputation as a reliable material standard. In real-world applications, case studies abound where low carbon steel wire has outperformed other options. A notable example involves its use in automotive manufacturing. Here, engineers prioritize materials that offer strength without sacrificing the flexibility necessary for forming complex geometries. Low carbon steel wire meets these criteria, resulting in increased adoption for the fabrication of vehicle frames and safety components. Feedback from these deployments often notes the reduction in material waste and cost savings during the production cycle. These concrete experiences from trusted industry voices underscore the intrinsic value that this material offers. Moreover, the bonding characteristic of low carbon steel wire elevates its trustworthiness among users. Its consistency in performance reduces the likelihood of failure under stress, ensuring reliability in structural applications. This trust is further amplified by empirical evidence collected over years of use, which consistently indicates its superiority in durability compared to higher-carbon alternatives, particularly in applications subjected to continuous load or impact. In conclusion, low carbon steel wire maintains its standing through a blend of cost-effectiveness, environmental compatibility, and practical utility. These properties, supported by extensive hands-on experience and professional endorsements, make it a material that builders, engineers, and architects turn to repeatedly. As industries advance and emphasize sustainable practices, the role of materials like low carbon steel wire becomes even more pivotal, promising continued relevance and application across various sectors.

Latest news

-

High-Quality Security Fence Supplier & Manufacturer Leading Exporter

NewsJun.24,2025

-

High-Quality Concrete Reinforcement Wire Mesh Leading Manufacturers & Exporters

NewsJun.10,2025

-

High Quality Galvanized Steel Fence - Leading Manufacturer, Exporter & Supplier

NewsJun.10,2025

-

10 Gauge Barbed Wire Supplier - Heavy-Duty & Corrosion-Resistant

NewsJun.10,2025

-

Durable Farm Fence Wire Suppliers & Manufacturers Fence Wire

NewsJun.10,2025

-

Premium Powder Coated Metal Mesh Suppliers - Durable & Rust-Resistant

NewsJun.09,2025