-

+86 15030157877

-

sales@galvanizedmetalmesh.com

When it comes to ensuring structural integrity, durability, and efficiency in construction projects, choosing the right wire mesh is crucial. At HEBEI WEICHUN WIRE MESH TRADE CO., LTD., we specialize in manufacturing high-performance construction wire mesh designed to meet the rigorous demands of modern building applications. Our products are engineered to enhance strength, prevent cracking, and provide reliable reinforcement for a wide range of construction needs.

For masonry and bricklaying projects, our Brick Mesh offers exceptional reinforcement, helping to distribute loads evenly and minimize the risk of cracks in walls and structures. Made from high-quality steel with precise welding, this mesh ensures long-lasting stability, making it an ideal choice for residential, commercial, and industrial construction. Whether used in brick walls, blockwork, or render applications, our brick mesh delivers superior bonding strength and resistance to thermal expansion, ensuring your structures remain solid and secure for years to come.

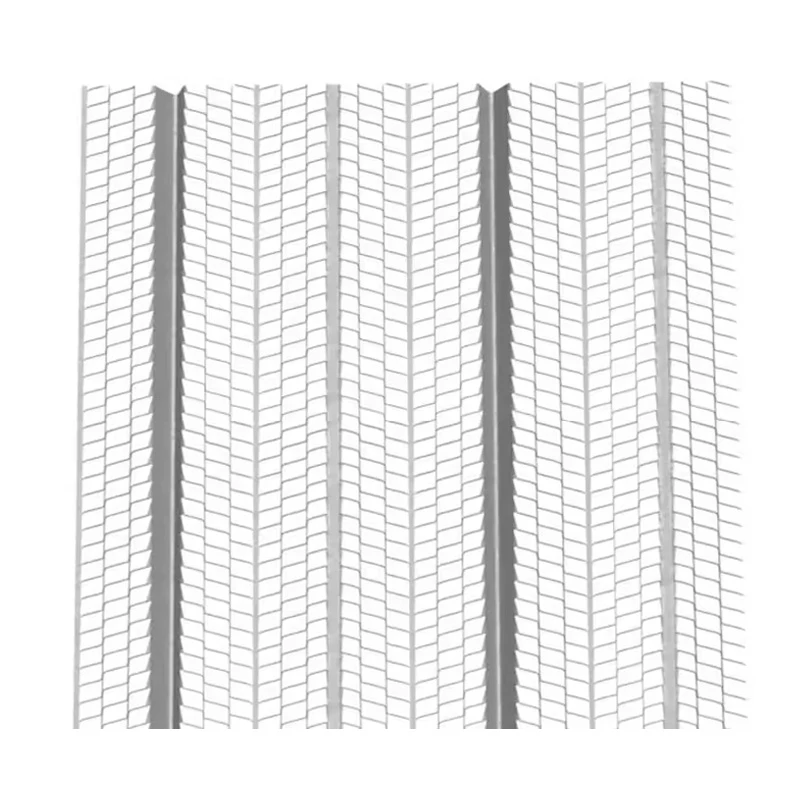

Another essential product in our construction lineup is Rib Lath, a versatile and robust solution for plastering and rendering. Its unique ribbed design provides excellent keying properties, allowing plaster and stucco to adhere firmly to surfaces. This makes it perfect for creating smooth, crack-free finishes on walls, ceilings, and facades. The rib lath’s lightweight yet durable construction also simplifies installation while maintaining high tensile strength, ensuring long-term performance in both interior and exterior applications.

Wire Mesh Often Used in Building & Construction Applications

Wire mesh has become an indispensable component in modern construction, serving multiple critical functions that enhance structural performance and longevity. One of its most significant applications is in concrete reinforcement, where welded or woven wire mesh is strategically placed within slabs, walls, and foundations. This reinforcement distributes tensile forces that concrete alone cannot withstand, effectively preventing cracks caused by shrinkage, settling, or heavy loads. In large-scale infrastructure projects like bridges, highways, and high-rise buildings, wire mesh ensures structural integrity while allowing for thinner concrete sections, optimizing material usage and cost efficiency.

Beyond structural reinforcement, wire mesh plays a vital role in masonry construction. When embedded between layers of brick or concrete blocks, it acts as a bonding agent, preventing separation and improving load distribution. This is particularly important in cavity wall construction, where the mesh ties together inner and outer wythes while allowing for thermal expansion. In plaster and stucco applications, wire mesh serves as a durable substrate, providing a mechanical key for coatings to adhere to while minimizing cracks caused by substrate movement or weathering.

The material's versatility extends to specialized applications like flooring systems, where it reinforces suspended slabs or industrial floors subjected to heavy traffic. In architectural designs, decorative wire mesh panels combine functionality with aesthetics, creating visually striking facades that provide shade, ventilation, and security. Safety applications include reinforcing glass in wired windows or creating protective barriers around mechanical equipment.

Modern wire mesh for construction is manufactured from high-tensile steel, often with protective coatings like galvanization or PVC to resist corrosion in harsh environments. Stainless steel variants are specified for projects requiring exceptional durability, such as coastal structures or chemical plants. With its ability to enhance strength, prevent cracks, and adapt to diverse construction needs, wire mesh remains a fundamental building material across residential, commercial, and industrial projects worldwide.

Types of Rib Lath

Rib lath represents a specialized category of expanded metal mesh engineered to provide superior reinforcement for plaster, stucco, and other architectural coatings. Its distinctive three-dimensional ribbed pattern creates an exceptional mechanical key for coatings to bond to, ensuring long-lasting, crack-resistant finishes. Among the various types available, galvanized rib lath stands out as the most common choice for general construction applications. The zinc coating provides reliable corrosion protection, making it suitable for both interior and exterior use in walls, ceilings, and soffits where moisture resistance is required.

For projects demanding enhanced durability, stainless steel rib lath offers superior performance in challenging environments. Its resistance to extreme temperatures, chemicals, and fire makes it ideal for industrial facilities, tunnels, and fireproofing systems where safety standards are stringent.

The technical specifications of rib lath can be customized based on project requirements. Heavy-duty versions with wider rib spacing are designed to support thick plaster coatings, while finer patterns are optimized for lightweight applications. The material's open design allows for excellent embedment of coatings while maintaining breathability, preventing moisture entrapment that could lead to delamination. Its lightweight yet rigid structure simplifies installation, reducing labor costs compared to traditional reinforcement methods.

From traditional plasterwork to modern Exterior Insulation and Finish Systems (EIFS), rib lath continues to be the substrate of choice for architects and contractors seeking durable, high-performance wall systems. Its ability to create stable, long-lasting surfaces while accommodating building movement makes it an essential component in both new construction and renovation projects across residential, commercial, and institutional buildings.

What is brick mesh used for?

Brick mesh, a specialized form of welded wire reinforcement, has become a critical component in contemporary masonry construction. Its primary function is to enhance the structural performance of brickwork and block walls by distributing stresses evenly throughout the structure. This reinforcement is particularly crucial in load-bearing walls of multi-story buildings, where it helps prevent cracking caused by differential settlement, thermal movement, or lateral forces like wind and seismic activity. The mesh is typically installed in horizontal mortar joints at regular intervals, creating a continuous reinforcement system that significantly improves the wall's tensile strength.

In cavity wall construction, brick mesh serves as an essential tie between the inner and outer wythes. These specially designed wall ties not only provide structural connection but also allow for necessary movement while maintaining the wall's integrity. The mesh's corrosion-resistant coatings, such as galvanizing or epoxy, ensure long-term durability even in damp conditions, making it suitable for external walls, basements, and other challenging environments. Modern variants include stainless steel brick mesh for projects requiring exceptional longevity, such as coastal buildings or chemical plants.

Beyond vertical applications, brick mesh finds extensive use in horizontal construction elements. When embedded in concrete ground slabs or brick paving systems, it controls cracking caused by shrinkage or ground movement. In reinforced brick beams and lintels, the mesh works in conjunction with steel bars to create structural elements that can span openings while maintaining the aesthetic appeal of brickwork. The material's versatility extends to renovation projects, where it can be used to stitch together and stabilize existing masonry that has developed cracks or shows signs of distress.