-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Aug . 19, 2025 01:20 Back to list

Durable Hexagonal Gabion for Erosion Control & Retaining Walls

Understanding the Strategic Role of Hexagonal Gabions in Modern Infrastructure

In contemporary civil engineering and environmental protection, the Hexagonal Gabion has emerged as an indispensable solution for a myriad of structural and erosion control applications. Its adoption reflects a significant industry trend towards sustainable, resilient, and cost-effective construction methodologies that can withstand dynamic environmental forces. Driven by increasing climate variability and the critical need for robust infrastructure, these engineered systems are increasingly specified by geotechnical engineers, landscape architects, and government agencies alike. The inherent flexibility of gabion structures allows them to adapt to ground deformation without losing structural integrity, a distinct advantage over rigid structures like concrete walls, which are prone to cracking under differential settlement. Furthermore, their porous nature ensures excellent drainage, mitigating hydrostatic pressure buildup behind retaining structures, a common cause of failure in conventional solid walls. This permeability also allows for the natural colonization of vegetation, fostering ecological integration and enhancing the aesthetic appeal of projects, aligning with contemporary green engineering principles. The burgeoning global investment in infrastructure development, particularly in developing regions susceptible to soil erosion and flood events, continues to fuel the demand for reliable and adaptable containment solutions such as the Hexagonal Gabion. This shift towards more environmentally symbiotic and economically viable construction practices underscores the long-term value and strategic importance of gabion technology in shaping the future of resilient infrastructure worldwide.

The design principles behind the Hexagonal Gabion leverage the inherent strengths of its components: the durability of high-tensile steel wire and the mass stability provided by the fill material, typically stones or rocks. This combination creates a composite structure that offers both strength and flexibility, crucial for retaining structures in challenging terrains or areas prone to seismic activity. The hexagonal mesh pattern, formed by double-twisting adjacent wires, provides exceptional integrity, preventing unraveling even if individual wires are cut. This specific weave ensures that the structure maintains its form and containment capacity under various stresses. Beyond traditional applications, innovations in gabion design and material coatings, such as PVC-coated wire, have expanded their utility to more aggressive environments, including marine applications or areas with highly corrosive soils. The longevity of these structures is also a key economic driver, as their service life often exceeds that of alternative solutions, requiring minimal maintenance and offering substantial long-term savings. The ability to source fill material locally further reduces transportation costs and environmental impact, reinforcing the economic and ecological benefits. As the industry continues to push for more sustainable and adaptable construction methods, the foundational principles and evolving applications of gabion technology solidify its position as a critical component in resilient infrastructure development, addressing both current challenges and future demands in civil engineering.

Precision Engineering: The Manufacturing Process of Hexagonal Gabions

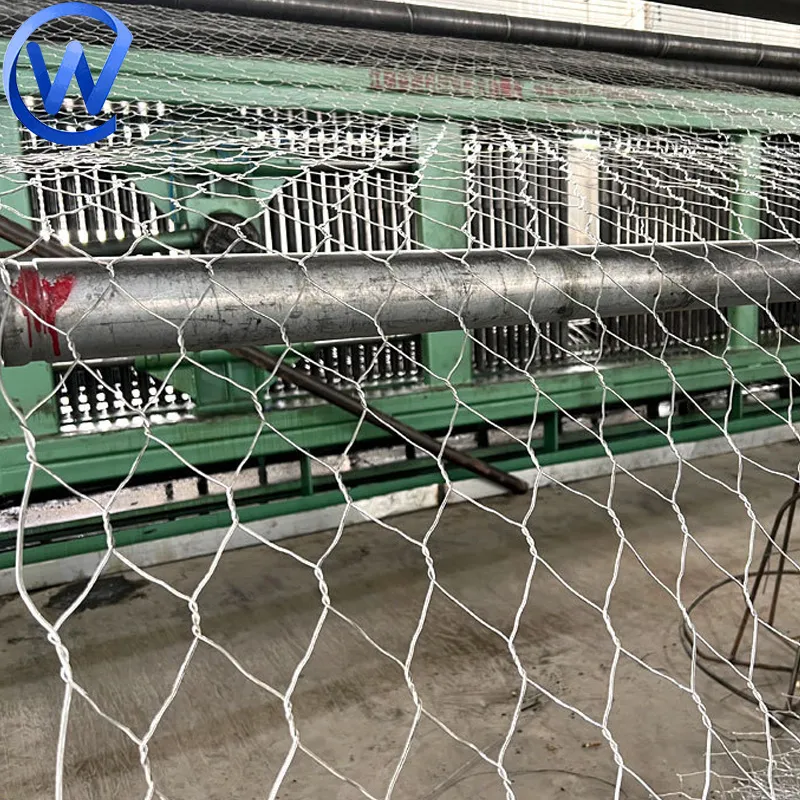

The production of Hexagonal Gabion systems is a sophisticated process that begins with the meticulous selection of high-quality raw materials. The primary material is low-carbon steel wire, carefully chosen for its specific tensile strength and ductility, which are critical for the double-twist weaving process and the ultimate structural integrity of the gabion. The manufacturing journey typically commences with wire drawing, where steel rods are systematically drawn through dies to achieve precise wire diameters, ranging commonly from 2.0 mm to 4.0 mm, depending on the required mesh strength and application. Following this, the wires undergo a rigorous corrosion protection treatment. The most common and effective method is heavy-duty galvanization, where wires are immersed in molten zinc to create a protective coating that adheres metallurgically to the steel, providing a barrier against rust and environmental degradation. For more aggressive environments, such as coastal areas or highly acidic soils, the galvanized wire is often further coated with a PVC (Polyvinyl Chloride) layer, which offers an additional layer of protection against chemical attack and abrasion, significantly extending the service life to 50 years or more in certain conditions. The next crucial step is the double-twist weaving process, performed by specialized machinery. This intricate weaving technique interlocks adjacent wires in a hexagonal pattern, creating a mesh that is incredibly stable and resistant to unraveling, even if a wire is cut, distinguishing it from welded mesh products. The precision of this weaving ensures uniform mesh openings and consistent wire spacing, both vital for predictable performance and compliance with international standards such as ASTM A975 and EN 10223-3.

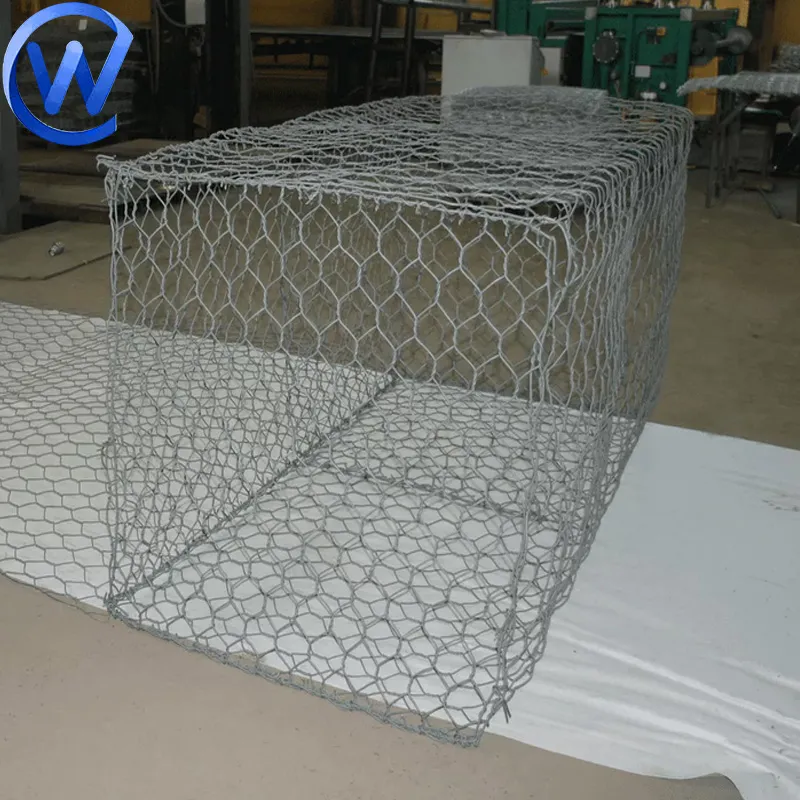

After the weaving, the continuous mesh is precisely cut into panels and then mechanically folded or assembled into the specific dimensions required for various Hexagonal Gabion units (e.g., boxes, mattresses, or sacks). Selvage wires, which are larger diameter wires (typically 0.5 to 1.0 mm thicker than the mesh wire), are incorporated along the edges of the panels. These selvage wires reinforce the structure, providing increased tensile strength at critical points and facilitating robust connections between adjacent gabion units during installation. Quality control is an integral part of every stage, from raw material inspection to the final product. Wires are subjected to tensile strength tests, coating thickness measurements (e.g., zinc coating weight per square meter exceeding 245 g/m² as per ASTM A641/A90, or PVC coating thickness around 0.5 mm), and mesh opening accuracy checks. These rigorous tests ensure compliance with stringent international standards like ISO 9001 for quality management systems and specific product standards like those from the American Society for Testing and Materials (ASTM) or European Norms (EN), guaranteeing consistent performance and reliability. The finished gabion units are then typically compressed and bundled for efficient transportation, arriving on-site as flat-packed units ready for assembly and filling. This comprehensive manufacturing process, characterized by precise engineering and adherence to strict quality protocols, ensures that each Hexagonal Gabion provides exceptional durability, structural integrity, and long-term performance in demanding civil and environmental engineering applications, excelling in areas like erosion control and stabilization where flexibility and permeability are paramount.

Technical Specifications and Performance Parameters of Hexagonal Gabions

The performance and suitability of a Hexagonal Gabion for a specific project hinge on a series of critical technical parameters, each contributing to its overall strength, durability, and effectiveness. Understanding these specifications is essential for engineers and project managers to ensure optimal design and longevity. The mesh wire diameter, typically ranging from 2.0 mm to 4.0 mm, directly influences the tensile strength of the mesh, with thicker wires providing greater resistance to tearing and deformation. Correspondingly, selvage wire diameters, usually between 2.7 mm and 4.0 mm, provide robust reinforcement along the edges, crucial for maintaining the structural form of the basket under load and during assembly. Mesh opening sizes, commonly 60x80 mm, 80x100 mm, or 100x120 mm, determine the size of the rock fill that can be contained, with smaller openings providing greater fill retention and often used in applications where finer aggregates are available or higher erosion resistance is required. The type and thickness of corrosion protection are paramount for long-term performance. Heavy-duty galvanization, adhering to standards such as ASTM A641/A90 with zinc coating weights typically exceeding 245 g/m², offers superior protection against atmospheric corrosion. For marine environments or highly corrosive soils, a PVC coating, with a nominal thickness of at least 0.5 mm, provides an additional durable barrier, significantly extending the design life of the gabion to several decades.

| Parameter | Typical Range/Value | Relevant Standard |

|---|---|---|

| Mesh Wire Diameter | 2.0 mm - 4.0 mm | ASTM A975, EN 10223-3 |

| Selvage Wire Diameter | 2.7 mm - 4.0 mm | ASTM A975, EN 10223-3 |

| Mesh Opening Size (approx.) | 60x80 mm, 80x100 mm, 100x120 mm | ASTM A975, EN 10223-3 |

| Wire Tensile Strength | 380 MPa - 550 MPa | ASTM A975, EN 10223-3 |

| Zinc Coating Weight | ≥ 245 g/m² | ASTM A641/A90, EN 10244-2 |

| PVC Coating Thickness (Nominal) | ≥ 0.5 mm | ASTM A975, EN 10223-3 |

| Standard Box Dimensions (L x W x H) | 1x1x1m, 2x1x1m, 3x1x1m, 4x1x0.5m | Manufacturer Specific |

Beyond these material and dimensional specifications, the overall performance of a Hexagonal Gabion structure is influenced by factors such as the quality of the rock fill, the compaction method, and the specific application's geotechnical conditions. The flexibility of the double-twist woven mesh allows the gabion structure to deform without fracturing, making it highly adaptable to ground movement and differential settlement, a significant advantage in seismically active regions or on unstable slopes. This inherent flexibility also enables gabions to accommodate hydraulic forces, dissipating energy from flowing water without compromising stability, making them ideal for river training works and channel linings. The permeability of gabion structures is another crucial technical attribute, allowing water to drain freely through the rock fill, preventing the buildup of hydrostatic pressure which can destabilize rigid retaining walls. This characteristic also contributes to their effectiveness in erosion control, as water can pass through the structure while sediment is retained. The ability of the galvanized or PVC-coated wire to resist corrosion over extended periods, combined with the structural integrity of the double-twist mesh, ensures that these systems offer a highly durable and long-lasting solution, often with a design life of 50 years for PVC-coated systems, significantly reducing the need for costly maintenance and reconstruction efforts over time.

Versatile Applications and Strategic Advantages of Hexagonal Gabions

The robust and adaptable nature of Hexagonal Gabion structures allows for their deployment across a broad spectrum of engineering and environmental applications. In civil engineering, they are extensively used for constructing retaining walls and bridge abutments, especially where foundation conditions are challenging or seismic activity is a concern. Their flexible nature allows the entire structure to settle and deform without fracturing, unlike rigid concrete structures, thereby maintaining stability under dynamic loads. For hydraulic engineering, gabions are indispensable for river training works, channel lining, and dam spillways. Their permeability prevents hydrostatic pressure buildup, while the mass of the rock fill dissipates the energy of flowing water, preventing erosion and protecting embankments. In coastal protection, gabion mattresses (a type of gabion with a large surface area and shallow depth) are deployed to stabilize shorelines, prevent scour, and mitigate the impact of wave action, offering a cost-effective and environmentally friendly alternative to traditional riprap. The inherent porosity of gabions also makes them highly effective in erosion control and slope stabilization projects, particularly on steep slopes or in areas prone to landslides. By providing a stable, permeable barrier, they prevent soil loss and promote vegetation growth, leading to natural, sustainable stabilization over time. This ecological integration is a significant advantage, as the voids within the rock fill provide microhabitats for flora and fauna, enhancing biodiversity and blending seamlessly with the natural landscape.

Beyond their structural and environmental advantages, Hexagonal Gabion systems offer significant economic benefits. The ability to utilize locally available rock fill significantly reduces transportation costs and carbon footprint compared to importing specialized materials. Installation, while requiring careful attention to assembly and filling, can be relatively straightforward, often utilizing local labor and basic construction equipment, contributing to cost-effectiveness and local economic development. The long service life of galvanized and particularly PVC-coated gabions, frequently exceeding 20-50 years with minimal maintenance, translates into lower lifecycle costs compared to many alternative solutions that may require frequent repairs or replacement. This durability, coupled with their inherent flexibility and permeability, results in highly resilient structures that perform reliably under various environmental stresses. Furthermore, the aesthetic versatility of gabions allows them to be integrated into landscape architecture and urban design, where they can form attractive retaining walls, noise barriers, or decorative elements, blending functionality with visual appeal. In industries such as mining, gabions are used for haul road stabilization and retaining structures, demonstrating their utility in even the most demanding industrial environments. The combination of structural stability, environmental compatibility, economic efficiency, and aesthetic integration positions the Hexagonal Gabion as a preferred choice for sustainable and effective infrastructure development across diverse sectors, including land reclamation, railway embankments, and protective works against rockfalls.

Selecting a Manufacturer: Customization and Quality Assurance for Hexagonal Gabion Solutions

When procuring Hexagonal Gabion solutions, the choice of manufacturer is paramount, directly influencing the project's long-term success, structural integrity, and cost-effectiveness. A reputable manufacturer differentiates itself through adherence to international quality standards, demonstrable technical expertise, and a robust capacity for customization. Key criteria for evaluation include ISO 9001 certification, which signifies a consistent commitment to quality management throughout the manufacturing process, from raw material sourcing to final product inspection. Furthermore, compliance with specific product standards such as ASTM A975 (for wire mesh gabions) and EN 10223-3 (for steel wire mesh for gabions) ensures that the gabions meet critical performance benchmarks for tensile strength, mesh integrity, and corrosion protection. Manufacturers with extensive service years in the industry often possess invaluable experience in diverse project types and geographies, allowing them to provide nuanced technical advice and problem-solving capabilities. It is crucial to assess a manufacturer's material sourcing and quality control protocols; for instance, verifying that their wire suppliers meet specific galvanization or PVC coating thickness requirements. Transparency in providing test data, such as certificates of analysis for wire tensile strength or zinc coating weight, builds significant trust and verifies product claims. Direct engagement with a manufacturer, rather than intermediaries, often facilitates more effective communication, streamlined logistics, and the ability to tailor solutions precisely to project specifications, which is particularly beneficial for large or complex infrastructure developments.

Customization capabilities are a significant advantage offered by leading Hexagonal Gabion manufacturers. While standard gabion box dimensions (e.g., 2x1x1m, 3x1x1m) are commonly available, many projects require bespoke sizes, specialized mesh openings, or unique coating specifications to address specific site conditions, environmental factors, or design aesthetics. For instance, projects in highly saline or acidic environments may necessitate specialized PVC or other polymer coatings with enhanced chemical resistance, while projects requiring integration into sensitive natural landscapes might call for specific wire or coating colors. A skilled manufacturer will offer engineering support to assist in optimizing gabion design for specific applications, including advice on appropriate wire gauges, mesh sizes, and connection methods (e.g., lacing wire, hog rings) to ensure structural stability and ease of installation. This consultative approach extends to understanding site logistics, potential challenges with local rock fill, and providing solutions for efficient delivery and assembly. Moreover, the manufacturer's commitment to after-sales support, including installation guidance, troubleshooting, and warranty provisions, is indicative of their long-term partnership approach. Companies that consistently invest in research and development to improve material science, manufacturing processes, and installation techniques demonstrate a forward-thinking approach, ultimately translating into superior product performance and value for their clients. Prioritizing manufacturers with a proven track record of timely delivery, consistent quality, and a proactive approach to customer service ensures that your Hexagonal Gabion project benefits from the highest standards of product excellence and technical backing.

Real-World Impact: Illustrative Application Cases of Hexagonal Gabions

The practical effectiveness of Hexagonal Gabion systems is best demonstrated through their successful application in diverse, real-world scenarios, showcasing their versatility and reliability in overcoming complex engineering challenges. Consider a large-scale river bank stabilization project in Southeast Asia, where seasonal monsoons caused severe erosion, threatening agricultural land and critical infrastructure. Here, PVC-coated gabion mattresses were deployed along extensive stretches of the riverbanks, forming a flexible, permeable revetment. The double-twist mesh, combined with the resilient PVC coating, withstood the abrasive forces of fast-flowing water and debris, while the rock fill dissipated hydraulic energy, effectively preventing further scour. Over time, vegetation naturally colonized the gabion voids, integrating the structure into the natural riparian ecosystem and providing additional long-term stability and aesthetic enhancement, demonstrating the environmental benefits beyond mere erosion control. Another compelling example involves the construction of a critical retaining wall for a new highway segment through a mountainous region in South America. Given the area's seismic activity and unstable geological conditions, traditional rigid concrete walls were deemed unsuitable due to the risk of cracking under differential settlement. Instead, a multi-tiered Hexagonal Gabion retaining wall system was chosen. Its inherent flexibility allowed the structure to accommodate minor ground movements without structural failure, providing a robust and resilient solution that conformed to the undulating terrain. The permeable nature of the gabions also prevented hydrostatic pressure buildup behind the wall, a common cause of failure in such contexts, ensuring long-term stability and safety for the newly constructed highway.

In urban landscaping and architectural projects, Hexagonal Gabions are increasingly being utilized for their aesthetic appeal and functional versatility. For instance, in a modern urban park development, gabion walls were designed not only to retain soil on sloped areas but also to serve as decorative seating elements and noise barriers. The natural texture of the stone fill, combined with the clean lines of the mesh, created a visually striking feature that harmonized with the contemporary design while providing essential practical functions. The ability to fill the gabions with a variety of local stones, or even recycled concrete, offered both cost savings and a nod to sustainable practices. Furthermore, in challenging remote environments, such as the construction of access roads for mining operations, gabions have proven invaluable. Their modular nature allows for relatively rapid deployment and construction using readily available local materials, reducing the logistical complexities and costs associated with transporting pre-fabricated components to distant sites. The robust wire mesh and stone fill resist the heavy loads and vibrations from mining machinery, providing durable and stable foundations and retaining structures. These diverse application cases underscore the inherent adaptability, structural resilience, and economic advantages of Hexagonal Gabion systems. They consistently demonstrate how these engineered solutions provide effective, sustainable, and visually appealing answers to a wide range of geotechnical, hydraulic, and environmental challenges faced by civil engineers and planners worldwide.

Frequently Asked Questions (FAQ) about Hexagonal Gabions

Q1: What is the typical service life of a Hexagonal Gabion structure?

The service life of a Hexagonal Gabion depends primarily on the type of wire coating and environmental conditions. Heavily galvanized gabions typically have a design life of 10-25 years in most atmospheric conditions. For more aggressive environments, such as coastal areas or highly acidic soils, PVC-coated gabions are recommended, offering an extended service life often exceeding 50 years. The longevity is also influenced by the quality of the rock fill, ensuring it is durable and resistant to degradation, as well as proper installation and maintenance practices. Our products undergo rigorous testing to ensure compliance with international durability standards, providing a reliable and long-lasting solution for various infrastructure projects.

Q2: Can Hexagonal Gabions be used in water-intensive applications like river training?

Absolutely. Hexagonal Gabion structures, particularly gabion mattresses, are exceptionally well-suited for water-intensive applications such as river training, channel lining, and dam spillways. Their inherent permeability allows water to flow through the structure, dissipating hydraulic energy and preventing hydrostatic pressure buildup behind the wall, which is a common cause of failure for rigid structures. The flexibility of the double-twist mesh also enables the structure to adapt to ground deformation and scour, maintaining integrity even under significant hydraulic forces. For submerged or intermittently submerged applications, PVC-coated gabions are strongly recommended due to their superior corrosion resistance in aquatic environments.

Q3: What type of fill material is recommended for Hexagonal Gabions?

The most common and recommended fill material for Hexagonal Gabion structures is durable, hard, angular, or sub-angular stone or rock. The size of the stones should be larger than the mesh openings to ensure retention within the basket. Typically, stone sizes range from 75mm to 250mm, depending on the mesh size. Materials should be resistant to weathering and degradation. Recycled concrete or other demolition debris can also be used, provided they meet the size and durability requirements and are free from contaminants. The choice of fill material can significantly impact the stability, permeability, and long-term performance of the gabion structure.

Commitment to Service: Delivery, Warranty, and Customer Support

Our commitment to clients extends far beyond the production of high-quality Hexagonal Gabion systems, encompassing robust logistics, comprehensive warranty provisions, and dedicated customer support. Understanding the critical nature of project timelines, we operate with highly efficient production and supply chain management systems designed to ensure prompt and reliable delivery of gabion products to project sites worldwide. Standard lead times typically range from 2 to 4 weeks for common specifications, though this can vary based on order volume, customization requirements, and specific shipping destinations. For urgent or large-scale projects, we offer expedited production and logistics solutions upon request, working closely with clients to meet challenging deadlines without compromising quality. Our packaging methods are optimized for secure transit and efficient handling at the destination, with flat-packed gabion units designed to minimize shipping volume and facilitate easy on-site assembly. Each shipment undergoes thorough quality checks before dispatch, ensuring that products arrive in perfect condition, ready for immediate deployment.

To underscore our confidence in the superior quality and durability of our Hexagonal Gabion products, we provide comprehensive warranty coverage. Our galvanized gabions typically come with a material warranty of 10-15 years against manufacturing defects and premature corrosion under normal environmental conditions, while our PVC-coated gabions are backed by an even more extensive warranty, often extending to 20-25 years. These warranties cover material integrity, wire coating adhesion, and resistance to unraveling under normal usage and proper installation, providing peace of mind and long-term assurance for your investment. Beyond the sale, our dedicated customer support team is available to provide expert technical assistance, from initial project consultation and product selection to installation guidance and troubleshooting. We offer detailed installation manuals, engineering design support, and can connect clients with experienced field technicians for complex project requirements. Our objective is to forge long-term partnerships with our clients, providing not just products, but complete solutions and unparalleled support throughout the entire lifecycle of their infrastructure projects. This holistic approach ensures that every Hexagonal Gabion project benefits from our expertise, commitment to quality, and unwavering dedication to customer satisfaction.

Conclusion: The Enduring Value of Hexagonal Gabions in Modern Engineering

The comprehensive examination of Hexagonal Gabion systems reveals their profound and expanding role in modern civil engineering, environmental protection, and landscape architecture. From their meticulous manufacturing process, adhering to rigorous international standards such as ASTM A975 and EN 10223-3, to their versatile application across diverse and challenging environments, gabions consistently deliver exceptional performance. Their inherent advantages—including unparalleled flexibility, superior permeability, robust durability, and remarkable adaptability to ground conditions—position them as a preferred solution over more rigid and less environmentally sympathetic alternatives. The economic benefits derived from utilizing locally available fill materials and their extended service life contribute significantly to reduced project lifecycle costs, aligning with global trends towards sustainable and economically viable infrastructure development. The ability to customize dimensions, coatings, and design for bespoke project requirements further enhances their utility, ensuring that specific site challenges can be met with tailored, high-performance solutions. As climate change continues to intensify natural hazards like erosion and flooding, the demand for resilient and adaptable construction materials will only grow. The Hexagonal Gabion, with its proven track record of structural integrity, environmental compatibility, and cost-effectiveness, stands as a testament to engineering excellence, offering an enduring and strategic solution for building a more resilient and sustainable future for infrastructure worldwide.

References

- ASTM A975/A975M-17, Standard Specification for Double-Twisted Hexagonal Mesh Gabions and Revet Mattresses (Metallic-Coated Steel Wire or Metallic-Coated and Poly(Vinyl Chloride) (PVC) Coated Steel Wire).

- EN 10223-3:2013, Steel wire and wire products for fencing and netting – Part 3: Steel wire mesh for gabions.

- ISO 9001:2015, Quality management systems – Requirements.

- Maccaferri. (2018). Gabions and Reno Mattresses: Flexible and Permeable Structures. Technical Manual.

- FHWA-SA-96-038, Design and Construction of Gabion and Revet Mattress Structures. Federal Highway Administration.

-

Durable Hexagonal Gabion for Erosion Control & Retaining Walls

NewsAug.19,2025

-

Durable & Stylish Roof Tiles for Lasting Home Protection

NewsAug.18,2025

-

Secure & Stylish Fences for Garden, Pool & Property Needs

NewsAug.17,2025

-

Find Your Perfect Fence: Durable, Secure, Affordable Solutions

NewsAug.16,2025

-

Custom Square Wire Mesh - High Quality, Wholesale Supply

NewsAug.15,2025

-

Custom & Wholesale Perforated Metal Mesh Sheets - Factory Direct

NewsAug.14,2025