-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Nov . 19, 2024 02:07 Back to list

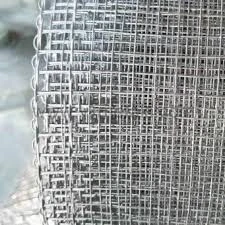

steel metal grating factories

The Impact of Steel Metal Grating Factories on Modern Infrastructure

Steel metal grating has become an essential component in various industries and infrastructure projects. With its durability, strength, and resistance to environmental factors, steel grating is widely used in construction, transportation, and manufacturing. The emergence of specialized factories dedicated to producing steel metal grating has significantly influenced how these materials are utilized, leading to advancements in design, safety, and overall industrial efficiency.

What is Steel Metal Grating?

Steel metal grating is a type of open grid flooring or platform that is manufactured from a series of parallel bars or rods, which are welded, riveted, or mechanically locked together. This structure allows for maximum air, light, and water circulation while providing a sturdy surface for foot or vehicular traffic. The applications of steel grating are vast, ranging from walkways and ramps to industrial flooring and drainage covers. Its versatility is an attractive feature for architects, engineers, and manufacturers alike.

Advantages of Steel Grating

One of the primary reasons for the widespread use of steel grating is its robust nature. It is designed to withstand heavy loads and resist wear and tear over time. Furthermore, steel grating is often coated with anti-corrosive materials or made from stainless steel, which enhances its longevity and further expands its potential use in harsh environments, such as factories, chemical plants, and outdoor installations.

Another significant advantage is safety. Steel grating can be designed with specific load ratings, ensuring that it can support intended weights without fail. Additionally, the open design of metal grating reduces the risk of slipping, especially in places prone to spillages or exposure to water. This feature is particularly important in industrial settings where worker safety is paramount.

The Role of Factories in Steel Grating Production

steel metal grating factories

Steel metal grating factories employ advanced manufacturing techniques to produce high-quality products that meet varied industry standards. These facilities often use automated machinery for cutting, welding, and finishing grating materials. Automation not only increases efficiency but also ensures precision, thereby reducing waste and lowering production costs.

Moreover, the presence of specialized factories contributes to the availability of customized solutions. Manufacturers can work closely with clients to produce steel grating tailored to specific dimensions, load requirements, and aesthetic preferences. This customization has opened new avenues for creativity in architecture and engineering, allowing for designs that were previously considered impractical.

Environmental Considerations

As industries increasingly recognize their impact on the environment, steel metal grating factories are also stepping up their efforts to reduce their carbon footprints. Many factories are adopting sustainable practices, such as recycling metal waste and using renewable energy sources in their production processes. These initiatives not only help to mitigate environmental damage but also enhance the public image of manufacturers committed to sustainability.

Furthermore, due to the long lifespan of steel grating, it contributes to sustainable construction practices. Its durability reduces the need for replacements and repairs, thus lessening resource consumption over time. When the grating does reach the end of its useful life, it can usually be recycled, contributing further to a circular economy.

Conclusion

The rise of steel metal grating factories has greatly impacted modern infrastructure by providing robust, versatile, and safe materials that cater to an array of applications. As industries continue to evolve, these factories play a crucial role in ensuring that quality and innovation keep pace with the demands of the market. The advantages of steel grating—ranging from safety to sustainability—coupled with advancements in production and customization, make it an indispensable choice for future infrastructure projects. The continued growth of this sector is likely to lead to further innovations that will benefit industries and communities alike. As we move forward, the collaboration between manufacturers, engineers, and design professionals will only enhance the functionality and aesthetic of steel metal grating in our everyday lives.

-

Durable Hexagonal Gabion for Erosion Control & Retaining Walls

NewsAug.19,2025

-

Durable & Stylish Roof Tiles for Lasting Home Protection

NewsAug.18,2025

-

Secure & Stylish Fences for Garden, Pool & Property Needs

NewsAug.17,2025

-

Find Your Perfect Fence: Durable, Secure, Affordable Solutions

NewsAug.16,2025

-

Custom Square Wire Mesh - High Quality, Wholesale Supply

NewsAug.15,2025

-

Custom & Wholesale Perforated Metal Mesh Sheets - Factory Direct

NewsAug.14,2025