-

+86 15030157877

-

sales@galvanizedmetalmesh.com

May . 07, 2025 19:15 Back to list

Galvanized Weld Wire Mesh Supplier High-Strength & Corrosion-Resistant

- Introduction to Galvanized Weld Wire Mesh

- Technical Advantages and Material Specifications

- Comparative Analysis of Leading Manufacturers

- Custom Solutions for Diverse Applications

- Performance Metrics and Industry Standards

- Case Studies: Real-World Implementations

- Why Partner with Trusted Galvanized Weld Wire Mesh Suppliers

(galvanized weld wire mesh)

Understanding the Versatility of Galvanized Weld Wire Mesh

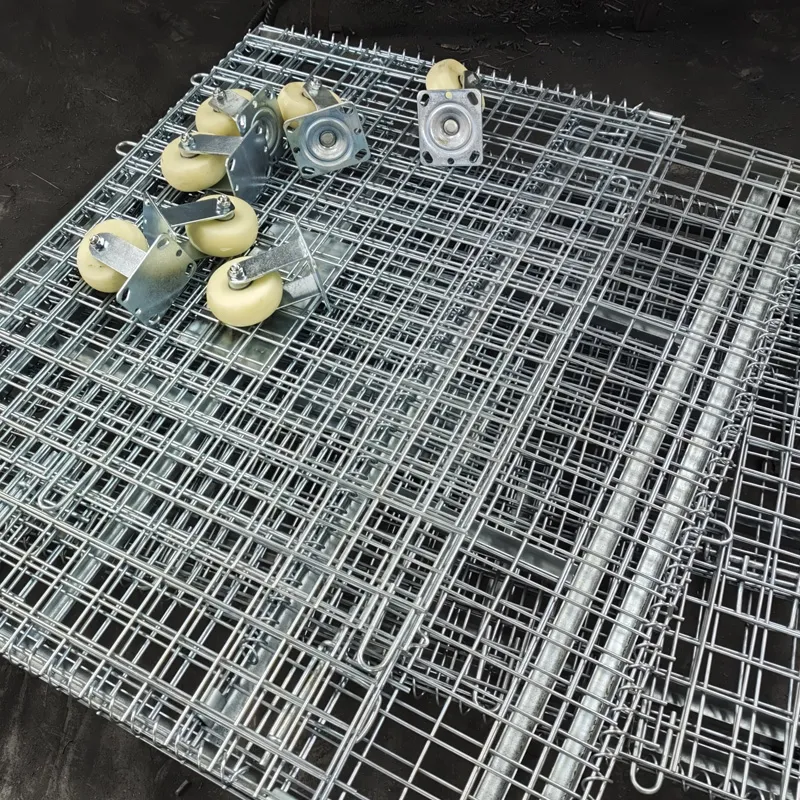

Galvanized weld wire mesh is a critical component in construction, agriculture, and industrial sectors due to its corrosion resistance and structural integrity. With a zinc coating thickness ranging from 20 to 50 microns, this material withstands harsh environments, offering a lifespan of 15–25 years. Exporters emphasize its adaptability, as it serves as fencing, reinforcement, and filtration media. The global market for welded wire mesh is projected to grow at a CAGR of 5.8% through 2030, driven by infrastructure development and automation in manufacturing.

Technical Superiority and Manufacturing Precision

High-quality galvanized weld wire mesh

relies on automated welding technology, ensuring consistent grid alignment and tensile strength (up to 550 MPa). Manufacturers employ hot-dip galvanization or electroplating, with the former providing superior rust protection. Key metrics include wire diameters (1.0–6.0 mm), aperture sizes (12–100 mm), and panel dimensions tailored to client requirements. Advanced producers utilize ISO 9001-certified processes, reducing defect rates below 0.3%.

| Manufacturer | Production Capacity | Certifications | Lead Time |

|---|---|---|---|

| Supplier A | 8,000 tons/month | ISO 9001, ASTM A740 | 10–14 days |

| Supplier B | 5,500 tons/month | CE, RoHS | 18–22 days |

| Supplier C | 12,000 tons/month | ISO 14001, BS EN 10223 | 7–10 days |

Tailored Solutions for Sector-Specific Demands

Leading galvanized weld wire mesh exporters offer customization in coating thickness, mesh patterns (square, rectangular, hexagonal), and edge treatments. For example, agricultural clients often request PVC-coated variants for animal enclosures, while construction projects require heavy-duty meshes with 6 mm wires. A recent automotive plant order involved 2,000 panels of 25x25 mm apertures with ±0.5 mm dimensional tolerance, processed within 72 hours.

Compliance and Durability Benchmarks

International standards like ASTM A185 (concrete reinforcement) and EN 10223-5 (fencing) govern production. Third-party testing confirms salt spray resistance exceeding 1,200 hours (ASTM B117) and elongation rates under 12%. Suppliers providing Mill Test Certificates (MTCs) gain preference in government tenders, particularly in North America and Europe.

Success Stories Across Industries

A poultry farm in Texas achieved 40% cost reduction by replacing wooden fences with galvanized mesh (30x30 mm, 3 mm wire), while a Singaporean marine contractor extended barrier lifespan from 5 to 18 years using hot-dip galvanized sheets. In renewable energy, a solar park in Spain utilized 12,000 m² of galvanized wire mesh for panel mounting structures, cutting installation time by 25%.

Selecting Reliable Galvanized Weld Wire Mesh Partners

Established suppliers differentiate through vertical integration—controlling steel sourcing, fabrication, and logistics. Top-tier galvanized weld wire mesh manufacturers maintain on-site labs for quality checks and provide BIM-compatible CAD files for architectural integration. With global container shortages impacting 78% of buyers in 2023, partners with FCA incoterms and warehousing networks ensure supply chain resilience.

(galvanized weld wire mesh)

FAQS on galvanized weld wire mesh

Q: What are the key advantages of using galvanized weld wire mesh?

A: Galvanized weld wire mesh offers superior corrosion resistance, durability, and strength, making it ideal for outdoor and industrial applications. The zinc coating protects against rust, extending the product's lifespan. It is widely used in fencing, construction, and agriculture.

Q: How does a galvanized weld wire mesh manufacturer ensure quality control?

A: Reputable manufacturers follow strict quality control processes, including material testing, precise welding techniques, and adherence to international standards like ASTM or ISO. Third-party inspections and certifications are often provided to guarantee product reliability.

Q: What should I consider when choosing a galvanized weld wire mesh exporter?

A: Prioritize exporters with proven industry experience, certifications, and positive client testimonials. Ensure they offer customizable sizes, competitive pricing, and reliable logistics support for timely global delivery.

Q: What industries commonly use galvanized weld wire mesh suppliers?

A: Suppliers cater to construction, agriculture, mining, and transportation industries. Applications include fencing, animal enclosures, concrete reinforcement, and safety barriers due to the mesh's versatility and robustness.

Q: Can galvanized weld wire mesh be customized for specific projects?

A: Yes, most manufacturers and suppliers offer customization in mesh size, wire thickness, and panel dimensions. Provide project requirements upfront to ensure the product meets exact technical and functional needs.

-

Premium Perforated Metal Mesh & Custom Sheets

NewsAug.07,2025

-

Premium Security Window Screen Mesh | Unmatched Safety

NewsAug.05,2025

-

Premium Artificial Grass Fence | AI Design Privacy Solution

NewsAug.04,2025

-

Premium Hexagonal Gabion Mesh Solutions | Durable & Eco-Friendly

NewsAug.03,2025

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025