-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Ene . 20, 2025 03:48 Back to list

Welded Wire Mesh

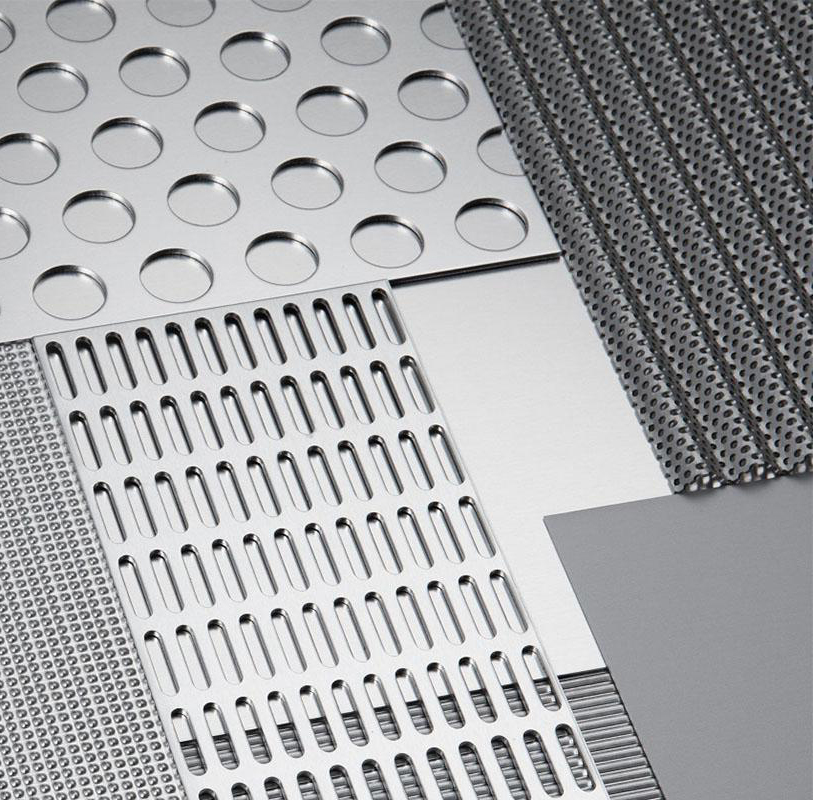

Square woven wire mesh, a versatile and essential product, stands as a cornerstone in various industries, thanks to its adaptability and robust nature. This intricate yet strong material plays a pivotal role in multiple applications, from industrial uses to architectural enhancements. Its utility and design flexibility make it invaluable, yet only those well-versed in its characteristics understand its full potential.

The mesh's enduring nature ensures it is not only a product of the moment but a long-term investment. Its recyclable materials make it an environmentally friendly choice, aligning with increasing global demands for sustainability in industrial practices. Experts assert that square woven wire mesh not only meets the robust physical demands of its varied applications but also fulfills a commitment to ecological responsibility. Choosing the right square woven wire mesh requires careful consideration of its intended application and environment. Professional consultation often leads to better-informed choices, maximizing both performance and lifecycle. Partnering with reputable manufacturers, well-versed in both the intricacies and broader applications of their products, ensures an informed decision and product reliability. Trustworthiness remains crucial in this domain. Buyers and practitioners alike rely on certified products that meet industry standards. The expertise offered by seasoned manufacturers guarantees that every piece of square woven wire mesh upholds quality and safety, reducing the risk of failure in critical applications. Certifications and rigorous testing procedures reflect a commitment to excellence, reassuring clients of their purchase's value and dependability. In conclusion, square woven wire mesh serves multiple industries, providing both critical functionality and appealing aesthetics. Its adaptability, coupled with expertly engineered design and production, underscores its significance across applications. The future of square woven wire mesh continues to shine brightly, driven by innovation and a demand for quality, reliable solutions in both industrial and artistic spheres.

The mesh's enduring nature ensures it is not only a product of the moment but a long-term investment. Its recyclable materials make it an environmentally friendly choice, aligning with increasing global demands for sustainability in industrial practices. Experts assert that square woven wire mesh not only meets the robust physical demands of its varied applications but also fulfills a commitment to ecological responsibility. Choosing the right square woven wire mesh requires careful consideration of its intended application and environment. Professional consultation often leads to better-informed choices, maximizing both performance and lifecycle. Partnering with reputable manufacturers, well-versed in both the intricacies and broader applications of their products, ensures an informed decision and product reliability. Trustworthiness remains crucial in this domain. Buyers and practitioners alike rely on certified products that meet industry standards. The expertise offered by seasoned manufacturers guarantees that every piece of square woven wire mesh upholds quality and safety, reducing the risk of failure in critical applications. Certifications and rigorous testing procedures reflect a commitment to excellence, reassuring clients of their purchase's value and dependability. In conclusion, square woven wire mesh serves multiple industries, providing both critical functionality and appealing aesthetics. Its adaptability, coupled with expertly engineered design and production, underscores its significance across applications. The future of square woven wire mesh continues to shine brightly, driven by innovation and a demand for quality, reliable solutions in both industrial and artistic spheres.

Next:

Latest news

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025