-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Oct . 02, 2024 23:59 Back to list

Low Carbon Steel Wire Production from Top Manufacturers for Various Applications

Low Carbon Steel Wire Manufacturer A Sustainable Choice

In recent years, the demand for low carbon steel wire has surged, driven by its versatile applications in various industries such as construction, automotive, and agriculture. As an essential material, low carbon steel wire offers a unique combination of strength, flexibility, and cost-effectiveness, making it an ideal choice for manufacturers looking to enhance their products while minimizing environmental impact.

Low carbon steel is characterized by its low carbon content, typically below 0.25%. This composition gives the wire excellent ductility and weldability, allowing it to be easily shaped and formed without compromising structural integrity. Manufacturers producing low carbon steel wire often leverage advanced technologies and quality control processes to ensure that their products meet stringent industry standards, thereby promoting safety and reliability.

As a responsible low carbon steel wire manufacturer, it is imperative to focus on sustainable practices throughout the production process. This includes sourcing raw materials from reputable suppliers who prioritize eco-friendly practices, utilizing energy-efficient manufacturing techniques, and implementing waste reduction strategies. By doing so, manufacturers not only reduce their carbon footprint but also contribute to a circular economy where materials are reused and recycled.

low carbon steel wire manufacturer

Moreover, investing in new technologies such as electric arc furnaces can significantly decrease greenhouse gas emissions associated with steel production. These furnaces utilize recycled scrap steel as their primary input, thus minimizing the need for virgin materials. Additionally, by optimizing production processes, manufacturers can improve energy efficiency and reduce overall operational costs, benefiting both the environment and their bottom line.

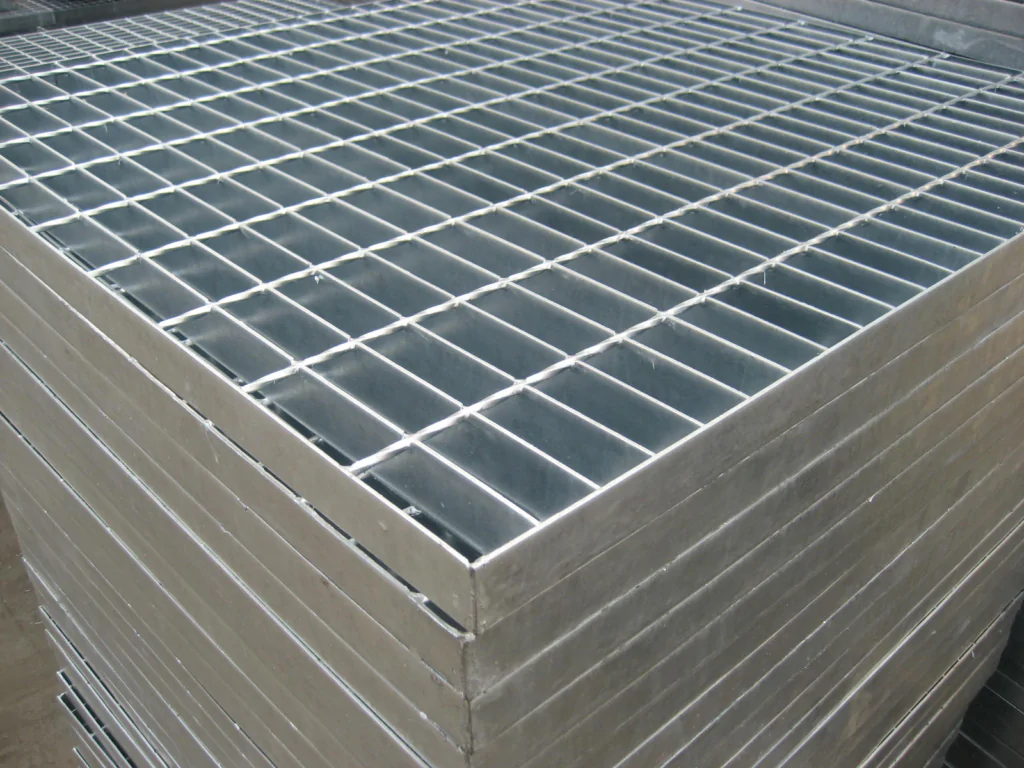

Furthermore, the versatility of low carbon steel wire opens doors to numerous applications, including reinforcing bars in construction, wire mesh for safety and security, and agricultural fencing. Its adaptability means that manufacturers can cater to a wide range of customers and industries, enhancing their market reach and potential for growth.

In conclusion, low carbon steel wire manufacturers play a crucial role in the progression towards a more sustainable and eco-friendly industrial landscape. By adopting innovative technologies, prioritizing sustainable practices, and focusing on quality, these manufacturers can meet the growing demand for low carbon steel wire while also contributing positively to the environment. This commitment to sustainability not only supports the planet but also paves the way for future generations, establishing a legacy of responsible manufacturing.

-

Premium Hexagonal Gabion Mesh Solutions | Durable & Eco-Friendly

NewsAug.03,2025

-

Smart AI Fence Solutions with GPT-4 Turbo | Secure & Fast

NewsAug.02,2025

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025