-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Jul . 28, 2025 11:01 Back to list

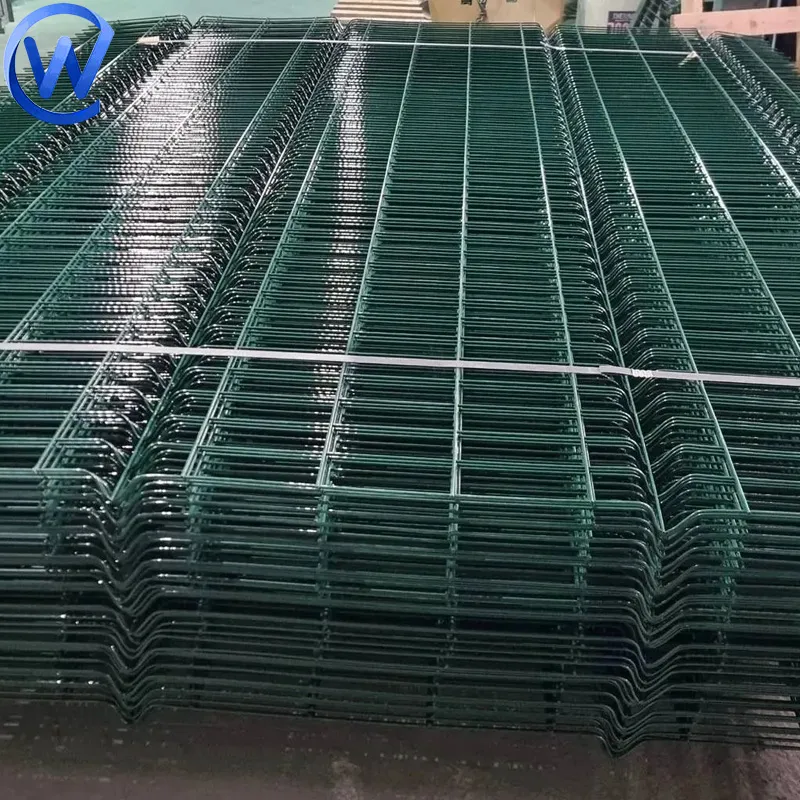

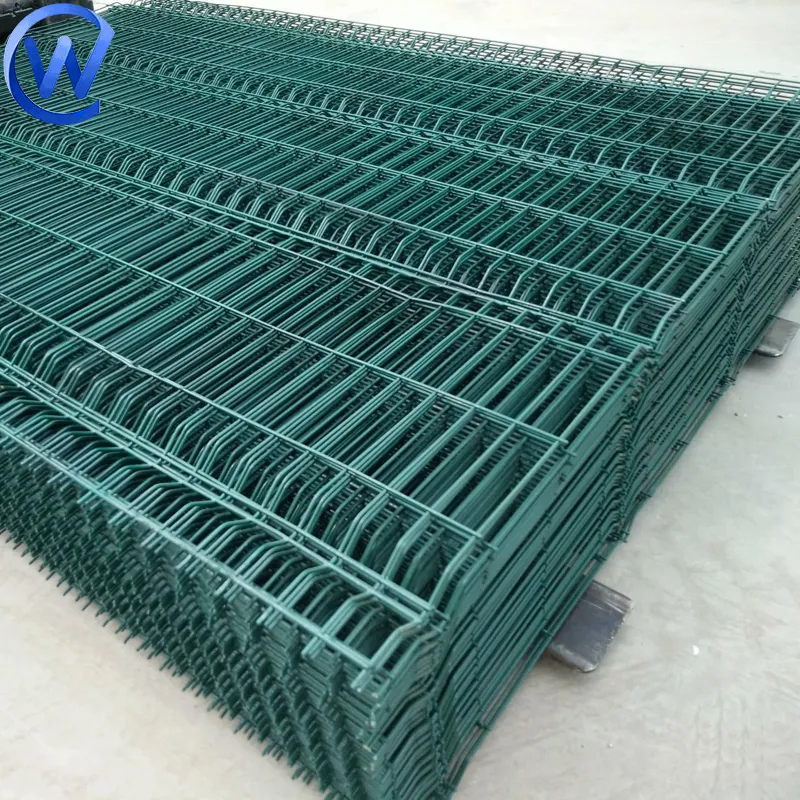

3D Curved Welded Wire Mesh Fence for Secure & Stylish Fencing Solutions

Over the past decade, the global 3D Curved Welded Wire Mesh Fence market has experienced significant growth—reaching a projected market size of USD 780 Million by 2025, expanding at a CAGR of 5.9% (Source: Grand View Research). With applications spanning industrial, petrochemical, urban infrastructure, utilities, and perimeter security, the adoption of 3D Curved Welded Wire Mesh Fence is driven by its superior strength-to-weight ratio, quick installation, and cost-effectiveness compared to traditional barrier systems.

Key trends shaping the sector include:

- Increasing urbanization demanding efficient, aesthetic fencing solutions

- Stricter safety & regulatory standards (ISO 1461, EN 10244-2)

- Rise in corrosion-resistant materials for extended lifespan

- Infrastructure upgrades in utilities and transportation hubs

- Growing use in high-voltage substations and water treatment facilities

The 3D Curved Welded Wire Mesh Fence is a robust security fencing system constructed from high-tensile galvanized steel wire, spot-welded at each intersection for optimal rigidity. Its distinctive V-shaped (3D) curves add further mechanical strength, minimizing deformation under impact and wind loads.

Key technical characteristics:

- Material: Low carbon steel Q195/Q235, hot-dip galvanized to EN/ISO 1461

- Wire diameter: 3.0mm–6.0mm (±0.05mm tolerance)

- Mesh size: 50x200mm, 75x150mm, 100x300mm

- Height: 1.2m, 1.5m, 1.8m, 2.0m, 2.4m, customizable

- Panel width: 2.0m, 2.5m, 3.0m

- Surface treatment: Galvanized (Zn > 60g/m²), powder coating (RAL 6005, 7016, 9005, etc.)

- Post type: 48mm/60mm round / 60x60mm/80x60mm rectangle, PE or powder coated

- ISO & CE Compliant (EN 10223-7 standard fencing wire mesh)

| Parameter | Standard Option 1 | Option 2 | Option 3 (Custom) |

|---|---|---|---|

| Panel Height (mm) | 1200 | 1800 | 2000–2400 |

| Panel Width (mm) | 2500 | 3000 | Any up to 3500 |

| Wire Diameter (mm) | 4.0 | 5.0 | 3.0–6.0 |

| Mesh Size (mm) | 50x200 | 75x150 | 100x300 |

| Curves Profile | 2 Curves | 3 Curves | Custom profile |

| Coating | Galvanized + Powder | Pure Galvanized | HDG or Duplex |

| Post Shape | Rectangular 60 x 60mm | Round 48mm | Custom |

| Color (RAL) | 6005 (Green) | 7016 (Anthracite) | Any |

The high-precision manufacturing process ensures that every 3D Curved Welded Wire Mesh Fence adheres to international standards such as ISO 9001:2015, ISO 1461, and ANSI/AWS welding standards.

- Raw Material Selection: Q235/Q195 wire coils, certified to ISO 4948-2 for chemical composition

- Straightening & Cutting: Automatic wire processing ensures length precision (±2.0mm)

- CNC Spot Welding: Cross-welding at grid nodes per EN 10223-7

- 3D Bending: Hydraulic press forms “V” curves for rigidity

- Galvanizing: Hot-Dip or Electro Galvanizing (zinc layer ≥ 60 μm)

- PVC/Powder Coating: High-resistance & UV tested per ASTM B117

- Quality Inspection: Dimensional, adhesion, salt-spray, and mechanical tests

Process Controls & Inspection Points: Each node is laser measured for alignment; zinc thickness tested by XRF spectroscopy; panels sampled for tensile strength (ISO 6892-1). Final inspection ensures compliance to ISO 1461 galvanizing and finish adhesion standards.

3D Curved Welded Wire Mesh Fence is engineered for high-performance environments where safety, durability, and low visual impact are essential. Major industries and typical deployment:

- Oil & Gas, Petrochemical Plants: Perimeter security in harsh atmospheres, thanks to anti-corrosive coating

- Metallurgy & Heavy Industry: Robotics area fencing, warehouse zoning

- Utilities (Water Treatment, Electrical Substations): Double insulation, minimization of stray current risks

- Municipal & Transportation: Public parks, airports, highways—urban aesthetics + high security

- Schools & Stadiums: Crowd management, anti-intruder barriers

- Residential/Commercial Real Estate: Landscaping, garden and pool fencing

Technical (Measured) Advantages:

- Corrosion Resistance: Salt Spray Test ≥ 1200 Hours (per ASTM B117)

- Mechanical Strength: Yield >420 MPa, Panel bending test > 250 cycles (no crack/fatigue)

- UV Stability: γ-radiation exposure, color loss <4%

- Service Life: > 20 years outdoor (lab simulated), > 5x chain-link alternatives

| Manufacturer | Annual Supply (Panels) | Major Certifications | Lead Time | Warranty | ISO/EN Standards |

|---|---|---|---|---|---|

| GalvanizedMeshProducts | XX,000+ | ISO9001, CE, SGS | 12–15 days | 10 years | EN10223-7, ISO1461 |

| Bekaert (EU) | 60,000+ | ISO14001, ISO9001, TÜV | 20 days | 10 years | EN10244-2 |

| Betafence (EU) | 70,000+ | ISO9001, CE | 25 days | 10 years | EN10223-7 |

| Anping Fencing (CN) | 50,000+ | ISO, BV, SGS | 14–17 days | 8 years | ISO1461 |

Every project is unique. 3D Curved Welded Wire Mesh Fence panels can be tailored to your specification—whether for anti-intruder, ornamental, or high-voltage zone requirements.

- Custom Mesh Openings – for anti-climb/safety by design

- Bespoke Colors – powder coating to any RAL code (UV/Weather resistant)

- Integrated Security Add-ons – razor wire, CCTV pole mounts, anti-vandal fasteners

- Non-standard Heights/Widths – match terrain or regulatory codes

- Specialized Surface Treatments – duplex coating, marine-grade galvanized

Petrochemical Plant Perimeter—Qatar, 2023

- 1200m of 3D Curved Welded Wire Mesh Fence installed within 18 days

- Features: 5mm HDG wire, triple V-curves, RAL 7016 finish

- Tested: 1600-hour salt spray, passed without coating degradation

- ISO/SASO-compliant installation with on-site QA

— Plant Security Manager, Qatar Chemical LLC

High School Stadium—Hungary, 2020

- 780m fencing coupled with CCTV posts and panic gates

- 4.5mm PVC powder coated mesh for maximum child safety

- Enhanced anti-climb profile; EN 1176 certified

Water Treatment Plant—Ontario, Canada, 2022

- Panel heights up to 2.4 meters, powder coated RAL 7037

- Non-conductive mounting hardware, double corrosion shield

- 40% cost reduction vs. palisade fencing

- Q1: What materials are used for 3D Curved Welded Wire Mesh Fence production?

- A: Mainly low carbon steel Q195/Q235. Surface finish: hot-dip galvanized, electro-galvanized, or powder coated after galvanizing for optimal longevity and corrosion resistance.

- Q2: What are the standard mesh opening sizes?

- A: Typical mesh openings are 50x200mm and 75x150mm, but custom mesh sizes up to 100x300mm are available based on application (e.g., anti-climb or decorative requirements).

- Q3: How is the fence tested for corrosion resistance?

- A: All panels undergo salt spray testing (ASTM B117, 1200+ hours). Zinc layer thickness is measured to comply with ISO 1461 (>60 μm).

- Q4: What installation standards apply?

- A: Installation follows EN 1991-1-4 (wind loading), EN 10223-7 (fencing mesh), and local safety codes. Foundation bolts and post mounting are designed per project loads.

- Q5: How does the 3D curve enhance panel strength?

- A: The “V”/3D bends increase inertia, reducing deformation from impact or wind, confirmed by mechanical lab tests >250 cycles with no structural failure.

- Q6: What is the service life & warranty?

- A: Standard outdoor service life is >20 years with periodic inspection. Product warranty: commercial 10 years for material & surface finish.

- Q7: Are colors and dimensions customizable?

- A: Yes—any RAL color, mesh size, panel length/height are possible. OEM logos and security add-ons available for bulk/commercial orders.

Technical Inquiries:

- Lead Time: 12–25 days (typical production + logistics)

- Packaging: Steel pallets, wrapped with EPE foam + waterproof PE film, barcode tracked

- Warranty: Material & finish—10 years (under normal outdoor usage)

- Quality Assurance: Full test report with shipment (SGS/BV/Materials Lab)

- Support: Free technical assistance (24h), site supervision, detailed installation guide PDF/video

- After-sales Service: Global replacement guarantee; on-site inspection available for major projects

This is the last article

-

3D Curved Welded Wire Mesh Fence for Secure & Stylish Fencing Solutions

NewsJul.28,2025

-

Spiral Plant Stick for Tomato Support - Durable & Easy to Install

NewsJul.27,2025

-

Stainless Steel Wire Mesh Roll Wholesale & Manufacturers – Quality Exporters

NewsJul.26,2025

-

High Quality 3D Curved Welded Wire Mesh Fence for Security and Aesthetics

NewsJul.25,2025

-

High-Quality Security Window Screen Mesh for Home & Office Protection

NewsJul.24,2025

-

Hexagonal Gabion for River Bank Protection and Retaining Walls

NewsJul.23,2025