-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Des . 30, 2024 14:26 Kembali ke daftar

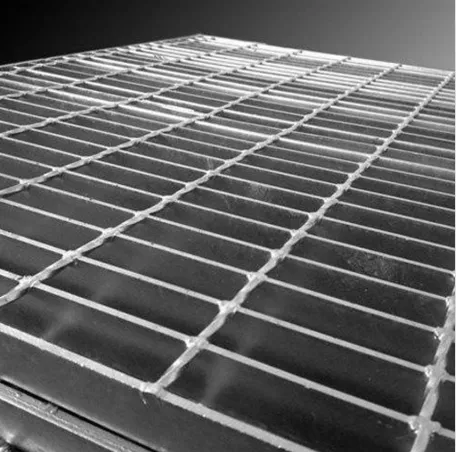

Galvanized Options and Pricing Insights of Steel Grating

Steel grating is a durable, versatile, and essential material used across a wide range of industrial and commercial applications. Whether for flooring, platforms, or walkways, steel grating provides strength and safety, making it a popular choice in various sectors. This article explores kisi baja, the benefits of kisi baja galvanis, and factors influencing steel grating prices.

What is Steel Grating?

Steel grating consists of a series of parallel, evenly spaced bearing bars joined by crossbars to create an open grid pattern. This design ensures high load-bearing capacity and optimal ventilation, drainage, and safety in various applications.

Common Uses of Steel Grating:

- Walkways and Platforms: In industrial facilities and public spaces.

- Trenches and Drains: For effective drainage and safety.

- Catwalks and Mezzanines: Offering stability with minimal weight.

- Stair Treads: Providing secure, slip-resistant surfaces.

Types of Steel Grating

Welded Steel Grating:

- Constructed through a welding process that joins bearing bars and crossbars.

- Common for heavy-load applications due to its robust structure.

Press-Locked Grating:

- Manufactured by pressing crossbars into bearing bars under high pressure.

- Offers a clean, uniform appearance and is ideal for architectural purposes.

Swage-Locked Grating:

- Utilizes a swaging process to interlock crossbars and bearing bars.

- Provides a strong and aesthetically appealing option.

Galvanized Steel Grating: Enhanced Durability

Galvanized steel grating is steel grating coated with a protective layer of zinc, making it resistant to corrosion and suitable for outdoor or harsh environments. The galvanization process enhances the lifespan of the grating by shielding it from rust, moisture, and wear.

Benefits of Galvanized Steel Grating:

- Corrosion Resistance: Ideal for outdoor and industrial settings where exposure to moisture or chemicals is frequent.

- Low Maintenance: Reduces the need for frequent repairs or replacements.

- Cost-Effective: While slightly more expensive initially, its longevity makes it a worthwhile investment.

Steel Grating Prices: Factors and Considerations

Understanding steel grating prices can be challenging, as they depend on several factors:

Material and Type:

- Galvanized Steeltypically costs more than untreated steel due to the protective coating.

- The type of grating (e.g., welded, press-locked) also affects pricing.

Dimensions and Specifications:

- Larger and thicker gratings cost more due to increased material usage.

- Custom specifications, such as unique shapes or specific load ratings, can lead to higher prices.

Market Conditions:

- Fluctuations in steel prices can influence the cost of grating products.

- Global supply chain issues and economic factors may also affect pricing.

Volume of Purchase:

- Bulk Orders: Purchasing in larger quantities can reduce the cost per unit, as many suppliers offer discounts for bulk purchases.

Tips for Choosing the Right Steel Grating

- Assess Load Requirements: Ensure the grating selected can support the intended load without deformation.

- Consider Environmental Conditions: For areas exposed to moisture, chemicals, or extreme weather, galvanized or stainless steel grating is recommended.

- Look for Compliance: Ensure the grating meets safety standards and regulations for your specific application.

Whether you need kisi baja for an industrial platform, a kisi baja galvanis option for enhanced durability, or are comparing steel grating prices, understanding the types, benefits, and influencing factors is essential for making an informed decision. Investing in the right type of steel grating can ensure long-term safety, functionality, and cost-effectiveness for your projects.

-

Stainless Steel Wire Mesh | 304/316, Factory Direct Prices

BeritaNov.17,2025

-

Stainless Steel Wire Mesh – Durable, Rust-Resistant, Exact

BeritaNov.17,2025

-

Expanded Metal Mesh: Custom, Durable, Factory-Direct Supply

BeritaNov.17,2025

-

Security Window Screen Mesh | Stainless Steel, Anti-Theft

BeritaNov.17,2025

-

Anti Bird Spikes Exporter – Durable Humane OEM Wholesale

BeritaNov.17,2025

-

Metal Mesh Fabric For Glass Laminated - UV-Stable, Custom

BeritaNov.11,2025