-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Jan . 15, 2025 05:02 Back to list

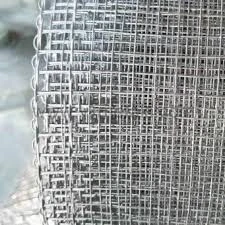

Steel Grating

Galvanized steel grating is a cornerstone in many industrial applications due to its durability, resistance to corrosion, and load-bearing capabilities. Experience dictates that when selecting materials for construction or industrial use, longevity and reliability are crucial. This is where galvanized steel grating stands out, thanks to its unique composition and manufacturing process that enhances its durability and performance even under harsh conditions.

In practical applications, galvanized steel grating is favored in settings where exposure to moisture, chemicals, and physical stress is prevalent. Industries ranging from petrochemical plants to food processing facilities rely on this type of grating to ensure safety and functionality. Real-world testing underscores its ability to withstand environments that would typically accelerate the wear and tear of less robust materials. The financial aspect is also crucial. Choosing galvanized steel grating can lead to cost savings over time. While the initial investment might be higher compared to alternatives, the reduced maintenance costs, combined with its long service life, provide better ROI. This economic efficiency further justifies its selection for large-scale projects. Moreover, the versatility of galvanized steel grating cannot be overstated. Available in a variety of sizes, shapes, and configurations, it can be tailored to meet specific project needs. Whether the requirement is for heavy-duty applications or more decorative purposes, like architectural facades, the customization options ensure that it fits seamlessly into any design or function without compromising its structural benefits. In conclusion, galvanized steel grating is not only a material of choice due to its inherent properties but also due to its proven track record in demanding industrial applications. Its ability to resist degradation over time, coupled with industry-backed endorsements and financial prudence, makes it an asset for anyone looking to optimize both the safety and efficiency of their project. As a result, engineering professionals continue to trust and advocate for its use, securing its position as a leading choice in construction and industrial materials.

In practical applications, galvanized steel grating is favored in settings where exposure to moisture, chemicals, and physical stress is prevalent. Industries ranging from petrochemical plants to food processing facilities rely on this type of grating to ensure safety and functionality. Real-world testing underscores its ability to withstand environments that would typically accelerate the wear and tear of less robust materials. The financial aspect is also crucial. Choosing galvanized steel grating can lead to cost savings over time. While the initial investment might be higher compared to alternatives, the reduced maintenance costs, combined with its long service life, provide better ROI. This economic efficiency further justifies its selection for large-scale projects. Moreover, the versatility of galvanized steel grating cannot be overstated. Available in a variety of sizes, shapes, and configurations, it can be tailored to meet specific project needs. Whether the requirement is for heavy-duty applications or more decorative purposes, like architectural facades, the customization options ensure that it fits seamlessly into any design or function without compromising its structural benefits. In conclusion, galvanized steel grating is not only a material of choice due to its inherent properties but also due to its proven track record in demanding industrial applications. Its ability to resist degradation over time, coupled with industry-backed endorsements and financial prudence, makes it an asset for anyone looking to optimize both the safety and efficiency of their project. As a result, engineering professionals continue to trust and advocate for its use, securing its position as a leading choice in construction and industrial materials.

Next:

Latest news

-

High-Quality Chicken Wire Panels Leading Manufacturer & Exporter

NewsJul.08,2025

-

High-Quality Concrete Reinforcement Wire Mesh – Reliable Steel Mesh Manufacturers & Exporters

NewsJul.08,2025

-

High-Quality Aluminum Expanded Mesh Leading Manufacturers & Exporters

NewsJul.08,2025

-

High-Quality Perforated Stainless Steel Sheet Manufacturer & Exporter Custom Sizes Available

NewsJul.07,2025

-

High-Quality Galvanized Angle Steel - Reliable Manufacturer, Exporter & Suppliers

NewsJul.07,2025

-

Premium Spiral Tomato Plant Support Stake Leading Manufacturer, Exporter & Supplier

NewsJul.06,2025