-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Lug . 31, 2025 02:40 Back to list

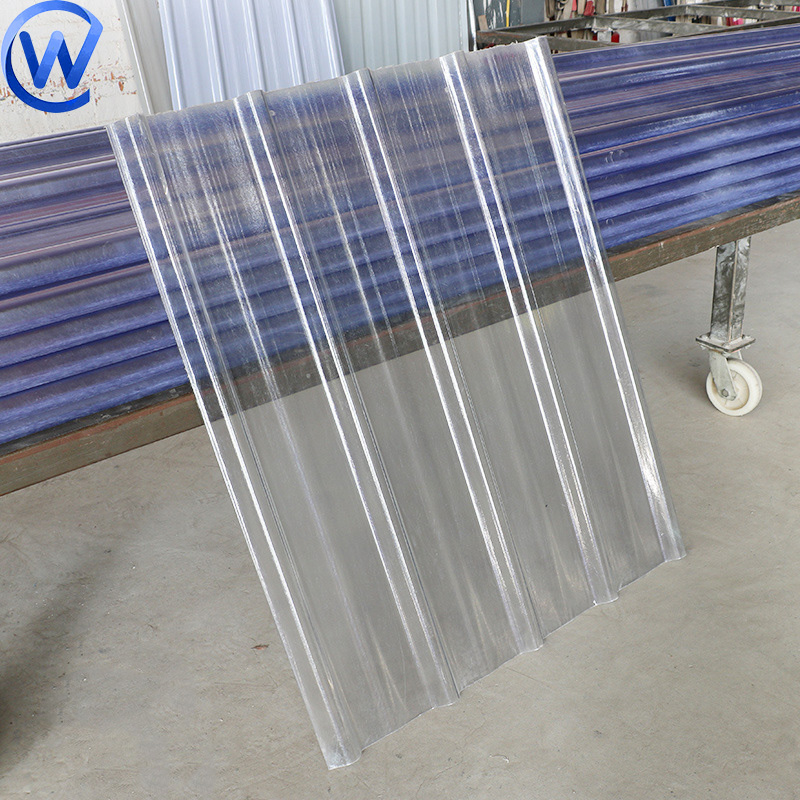

Premium Eco-Friendly Roof Tiles | Affordable & Durable

Industry Overview & Market Trends

As the global construction market shifts towards energy efficiency, durability, and low-maintenance solutions, Roof Tiles have gained unprecedented momentum. According to Research and Markets, the worldwide roof tile market is projected to reach 20.4 billion USD by 2028, with a CAGR of 5.1%. The demand is particularly driven by urbanization, sustainable building codes, and advances in material science—particularly in galvanized steel, clay, and polymer-modified surfaces.

Main Technical Parameters of Roof Tiles

| Parameter | Galvanized Steel Tiles | Ceramic Tiles | Composite Polymer Tiles |

|---|---|---|---|

| Thickness (mm) | 0.4 – 1.2 | 7 – 14 | 4 – 10 |

| Standard Size (mm) | 220 x 320, 300 x 400 | 270 x 410, 300 x 400 | 230 x 420, Custom |

| Weight per Tile (kg) | 0.47 – 1.90 | 2.2 – 3.5 | 0.41 – 1.23 |

| Compressive Strength (MPa) | ≥ 310 | ≥ 100 | ≥ 200 |

| Coating/Finish | Zinc/Aluminum Alloy, RAL Color Coated | Natural Glaze | UV, Color-fast Polymer |

| Service Life (Years) | 30 – 50 | 25 – 70 | 25 – 45 |

| Anti-corrosion Standard | ISO 9223 / EN 10346 | ISO 28706 | ASTM D2247 |

| Fire Resistance | Class A (ASTM E108) | Class A (ASTM E108) | Class B – A (Custom) |

Manufacturing Process of Roof Tiles – Full Workflow Explained

Flowchart: From Raw Material to High-Quality Roof Tiles

Technical Advantages & Performance Features of Roof Tiles

- ✔ Corrosion Resistance: Multi-layer hot-dip galvanized or polymer coatings provide years of weather protection. Salt spray tests confirm resistance up to 1200 hours (per ISO 9227).

- ✔ Precision Fit: CNC-formed dimensions ensure consistent overlap and water tightness, compatible with both industrial and residential systems.

- ✔ Energy Efficiency: Reflective coatings and optional insulation backings reduce cooling loads by up to 18% (US DOE data).

- ✔ Longevity: Service life up to 50 years with minimal maintenance under standard conditions (documented by client case studies).

- ✔ Modular Production: Flexible sizes and colors for any architectural demand, allowing easy on-site replacement and upgrades.

- ✔ Third-party Certifications: Products meet ISO 9001, ISO 9223, ANSI/SPRI ES-1 and ASTM E108 fire ratings, ensuring global compliance.

Manufacturer & Supplier Comparison: Roof Tiles Market Leaders

| Brand | Location | Specialization | Certifications | Notable Clients |

|---|---|---|---|---|

| Tejas Borja | Spain | Ceramic Roof Tiles, Solar Tiles | ISO 9001, CE | Acciona, Via Célere |

| Boral Roofing | USA | Concrete & Clay Tiles | ISO 14001, FM Approvals | Lennar, DR Horton |

| Monier Redland | Germany | Steel Tiles, Modular Systems | ISO 9223, EN 10346 | BASF, BMW Group |

| GalvanizedMeshProducts | China | Galvanized Steel Roof Tiles | ISO 9001, ANSI/ASTM | Saudi Aramco, Sinopec |

| Onduline | France | Bitumen & Polymer Tiles | ISO 14025, BBA | Vinci, SNCF |

Customization for Your Projects: Tailored Roof Tiles Solutions

- Material: Select from galvanized steel (Z275-Z450), Aluminum, Polymer, or Ceramic for your application needs.

- Color & Surface: Choose from glossy, matte, anti-slip or UV-resistant color coatings (RAL, Pantone ref.).

- Shape & Size: Design support for complex architectural curves, side laps, hidden fastener types, and widths from 180mm to 600mm.

- Accessories: Matching ridge caps, ventilation profiles, integrated solar modules, snow guards.

- Engineering Drawings: 2D/3D CAD support and BIM file delivery for precise project integration.

- Standards: Fully compliant with ISO, ANSI, ASTM, EN. Custom certificates upon request.

- MOQ: 300 m² for standard, 600+ m² for full customization.

* For custom quotations, visit Roof Tiles official page.

Application Scenarios & Industry Use Cases

1. Petrochemical Storage Warehouses

Roof Tiles with anti-static finishes and Class A fire rating used for roofs of chemical storage, reducing risk of corrosive vapor damage. Capable of lasting over 18 years in C5-class industrial zones (Third-party test: SGS report, 2022).

2. Municipal Water Plants

Utilized for their corrosion, algal, and mold resistance, steel-based Roof Tiles (ISO 12944 compliant) protect structures exposed to consistent high humidity and chemical cleaning.

3. Metallurgical Factories & Warehouses

Heavy-duty Roof Tiles withstand temperature fluctuations, airborne particles, and mechanical load (rush loads up to 750 kg/m²), ensuring uninterrupted production even in harsh environments.

4. Public Infrastructure & Transportation Hubs

Composite and color-matched Roof Tiles offer architectural flexibility for airports, train stations, stadiums—reducing long-term refurbishment costs.

Application Success: Real Project Case Studies & Customer Feedback

Saudi Aramco Crude Oil Storage Expansion (2022)

- Scope: 52,000 m² of galvalume Roof Tiles supplied.

- Performance: Average site corrosion loss after 19 months: <1.5μm (ISO 9227 salt spray reports).

- Feedback: “Minimal installation wastage, no leaks – product exceeded life cycle modeling.” (Plant Engineer, 2023)

Western EU Wastewater Treatment Plants (2019-2022)

- Scope: Polymer-coated steel tiles on 18,500 m² of sloped roofs.

- Test Data: Zero fungal growth over 3 years, lower maintenance by 14% avg.

- Customer Note: “Most reliable roof solution in aggressive chemical zones.”

Technical FAQ – Professional FAQ on Roof Tiles

Delivery Times, Warranty, and Client Support

- Delivery Cycle: 15–25 working days for standard orders, expedited service for urgent projects (as low as 7 days).

- Warranty: 10–40 years based on finish/system and environment.

- Support: Dedicated technical team for design, site training, and custom documentation—available 24/7 via Roof Tiles contact portal.

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025