-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Set . 22, 2024 13:43 Back to list

stainless steel wire mesh factories

The Rise of Stainless Steel Wire Mesh Factories A Key Industry in Modern Manufacturing

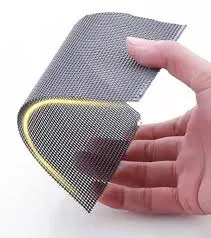

In an ever-evolving industrial landscape, the significance of stainless steel wire mesh factories has surged dramatically. As a versatile material with outstanding properties, stainless steel wire mesh finds applications across various sectors, including construction, aerospace, automotive, and food processing. The combination of durability, corrosion resistance, and aesthetic appeal makes it a preferred choice for manufacturers worldwide.

Stainless steel wire mesh is typically made from a high grade of stainless steel, which provides strength and longevity. This mesh is produced by weaving or welding wires together to form a grid pattern, creating a fabric-like material that can be cut and formed into various shapes and sizes. The manufacturing process has advanced significantly; modern factories employ cutting-edge technology and automated systems to enhance efficiency and consistency, ensuring that the final product meets stringent quality standards.

One of the primary advantages of stainless steel wire mesh is its resistance to rust and corrosion. This property makes it particularly useful in environments prone to moisture and chemical exposure, such as in marine applications or in the food industry, where hygiene is paramount. Many stainless steel wire mesh factories utilize various grades of stainless steel, such as 304 and 316, each suited to specific environments and applications. Grade 316, for instance, offers enhanced corrosion resistance, making it ideal for coastal applications or industrial settings where chemicals are present.

stainless steel wire mesh factories

The diversity of stainless steel wire mesh applications is impressive. In construction, it is used for reinforcing concrete, providing structural integrity to buildings and bridges. In the automotive industry, it serves as filtration material and mesh screens for various components, contributing to overall safety and performance. In the food sector, stainless steel wire mesh is essential for sieving, filtering, and protecting food products, ensuring compliance with health regulations.

The rapid globalization of industries has opened up export markets for stainless steel wire mesh factories. Countries with abundant resources and skilled labor, such as China and India, have emerged as key players in the global market. These factories not only supply local demand but also meet the growing needs of international clients. With economies continuing to expand, the future of stainless steel wire mesh production appears promising, with factories adapting to the evolving standards of safety and sustainability.

Sustainability is becoming increasingly important in manufacturing processes. Many stainless steel wire mesh factories are now focusing on eco-friendly practices, such as reducing waste and energy consumption. The recyclability of stainless steel itself contributes to sustainable practices, as it is one of the most recycled materials worldwide. This commitment to sustainability not only meets regulatory requirements but also appeals to environmentally conscious consumers.

In conclusion, stainless steel wire mesh factories play a crucial role in meeting the demands of modern industries. With their ability to produce high-quality materials that withstand harsh environments and contribute to the functionality of various applications, these factories are essential in both local and global manufacturing landscapes. As technology advances and sustainability becomes a priority, the future of stainless steel wire mesh production looks more promising than ever, ensuring that these factories will remain vital components of industrial progress.

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

Hexagonal Gabion for Slope Protection & Retaining Walls | Durable Wire Mesh

NewsJul.29,2025

-

3D Curved Welded Wire Mesh Fence for Secure & Stylish Fencing Solutions

NewsJul.28,2025