-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Jan . 28, 2025 02:02 Back to list

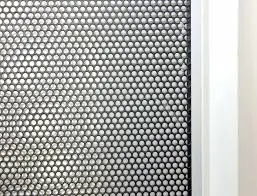

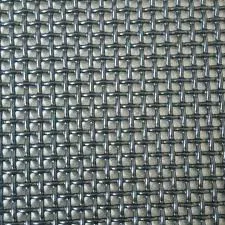

brick coil mesh

Navigating the construction and architectural landscapes requires more than just a keen eye for design—it demands materials that are versatile, durable, and innovative. One product that has emerged as a game-changer in the industry is the brick coil mesh. This seemingly simple but ingeniously crafted material encompasses a wealth of advantages, each offering unique benefits to architects, contractors, and builders alike.

The expert perspective on brick coil mesh often includes its contribution to sustainability—a crucial consideration in today's eco-conscious world. Many manufacturers produce mesh options from recycled metals, significantly reducing the environmental impact associated with new construction materials. This approach aligns with green building standards, offering LEED (Leadership in Energy and Environmental Design) points to projects that prioritize sustainable practices. In terms of authority, brick coil mesh's performance is backed by rigorous testing and industry compliance. The material meets and often exceeds building code requirements, providing peace of mind to engineers and architects concerned with safety and regulations. The standardized production ensures consistency in quality, eliminating the variability that can be incurred with less reliable materials. Trustworthiness in construction materials is non-negotiable, and the reputation of brick coil mesh as a dependable choice is well-documented. Case studies and user testimonials abound, illustrating successful applications in various conditions. The material’s widespread adoption in seismic regions, for instance, attests to its capacity to maintain structural integrity amidst dynamic stresses. Ultimately, the decision to incorporate brick coil mesh into a construction project should be informed by a thorough understanding of its benefits. The real-world experience of builders coupled with expert insights suggests that it is an innovative solution that addresses both practical and aesthetic needs. By integrating brick coil mesh, professionals contribute to creating structures that are not only striking and sustainable but also sturdy and secure, embodying the future of forward-thinking construction practices.

The expert perspective on brick coil mesh often includes its contribution to sustainability—a crucial consideration in today's eco-conscious world. Many manufacturers produce mesh options from recycled metals, significantly reducing the environmental impact associated with new construction materials. This approach aligns with green building standards, offering LEED (Leadership in Energy and Environmental Design) points to projects that prioritize sustainable practices. In terms of authority, brick coil mesh's performance is backed by rigorous testing and industry compliance. The material meets and often exceeds building code requirements, providing peace of mind to engineers and architects concerned with safety and regulations. The standardized production ensures consistency in quality, eliminating the variability that can be incurred with less reliable materials. Trustworthiness in construction materials is non-negotiable, and the reputation of brick coil mesh as a dependable choice is well-documented. Case studies and user testimonials abound, illustrating successful applications in various conditions. The material’s widespread adoption in seismic regions, for instance, attests to its capacity to maintain structural integrity amidst dynamic stresses. Ultimately, the decision to incorporate brick coil mesh into a construction project should be informed by a thorough understanding of its benefits. The real-world experience of builders coupled with expert insights suggests that it is an innovative solution that addresses both practical and aesthetic needs. By integrating brick coil mesh, professionals contribute to creating structures that are not only striking and sustainable but also sturdy and secure, embodying the future of forward-thinking construction practices.

Next:

Latest news

-

High-Quality Security Fence Supplier & Manufacturer Leading Exporter

NewsJun.24,2025

-

High-Quality Concrete Reinforcement Wire Mesh Leading Manufacturers & Exporters

NewsJun.10,2025

-

High Quality Galvanized Steel Fence - Leading Manufacturer, Exporter & Supplier

NewsJun.10,2025

-

10 Gauge Barbed Wire Supplier - Heavy-Duty & Corrosion-Resistant

NewsJun.10,2025

-

Durable Farm Fence Wire Suppliers & Manufacturers Fence Wire

NewsJun.10,2025

-

Premium Powder Coated Metal Mesh Suppliers - Durable & Rust-Resistant

NewsJun.09,2025