-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Nov . 28, 2024 06:53 Back to list

Top Exporters of 10% Gauge Wire Mesh for Global Markets and Applications

The Role of 10% Gauge Wire Mesh Exporters in the Global Marketplace

In today's fast-paced construction and manufacturing industries, the demand for high-quality materials is paramount. Among these, wire mesh stands out as an essential component utilized in various applications, including construction, fencing, filtration, and architectural designs. Specifically, 10% gauge wire mesh exporters play a critical role in meeting global demand, ensuring that businesses have access to reliable and durable materials.

Understanding 10% Gauge Wire Mesh

Wire mesh is categorized based on the thickness of the wire used to create it. The term 10% gauge often refers to the wire diameter, which is approximately 0.102 inches. This specific gauge strikes a balance between strength and flexibility, making it suitable for a wide array of applications. For instance, in construction, it provides structural support in concrete, enhances the durability of buildings, and assists in controlling cracks. In agriculture, it is used for fencing and animal enclosures, promoting safety and security.

The Export Market Dynamics

Exporting 10% gauge wire mesh is not just about selling a product; it involves understanding the dynamics of international trade. Exporters must navigate complex regulations, quality assurance standards, and varying market demands. Countries with robust construction and manufacturing sectors, such as the United States, Germany, and China, are among the largest markets for wire mesh. Local regulations often dictate the specifications required, making it vital for exporters to stay aware of these conditions.

Quality Assurance and Standards

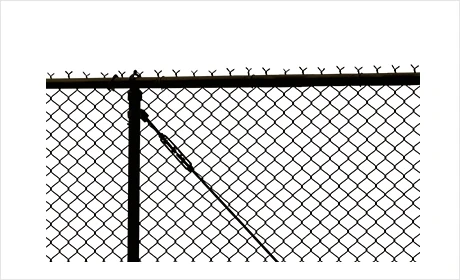

10 gauge wire mesh exporter

Quality is a driving factor in the wire mesh industry. Exporters need to adhere to international quality standards to ensure their products are safe and effective. Compliance with standards such as ISO 9001 can help exporters build credibility in the market. Additionally, conducting rigorous quality tests—such as tensile strength tests and corrosion resistance assessments—is crucial for gaining the trust of international clients. The durability of wire mesh often depends on its material composition, and zinc-coated or galvanized wire is often preferred for its resistance to rust and corrosion.

Innovation in Manufacturing

As industries evolve, so do the methods of manufacturing wire mesh. Exporters are increasingly adopting innovative techniques to improve production efficiency and reduce costs. Advanced machinery and technology allow for precision in wire cutting and welding, producing mesh with more consistent quality. Furthermore, automation in manufacturing processes can significantly enhance productivity while ensuring a high level of quality control.

Sustainability in Exports

Sustainability is becoming a significant consideration in international trade. Wire mesh exporters are exploring eco-friendly practices by using recycled materials and reducing waste during manufacturing. Meeting the sustainability expectations of modern consumers not only helps exporters maintain a competitive edge but also aligns with global efforts to address climate change.

Conclusion

In a world where construction and manufacturing continually demand innovative materials, 10% gauge wire mesh exporters hold a pivotal role. By understanding market dynamics, ensuring quality, embracing technological advancements, and adopting sustainable practices, exporters can thrive in the competitive landscape. As global infrastructure projects expand and the need for durable, reliable materials increases, these exporters will continue to be essential contributors to the global marketplace, ensuring that businesses and consumers receive the best possible products for their needs.

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025