-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Dec . 05, 2024 14:02 Back to list

Factories Producing 10% Gauge Wire Mesh for Various Industrial Applications

Understanding 10% Gauge Wire Mesh Factories An Overview

In the world of construction and manufacturing, the quality of materials used is paramount to ensure safety, efficiency, and longevity. Among the essential materials that contribute significantly to construction and industrial applications is wire mesh. Specifically, the 10% gauge wire mesh plays a vital role in various projects, and understanding its production process and significance offers valuable insights. This article delves into the workings of 10% gauge wire mesh factories, the characteristics of wire mesh, and its applications.

What is 10% Gauge Wire Mesh?

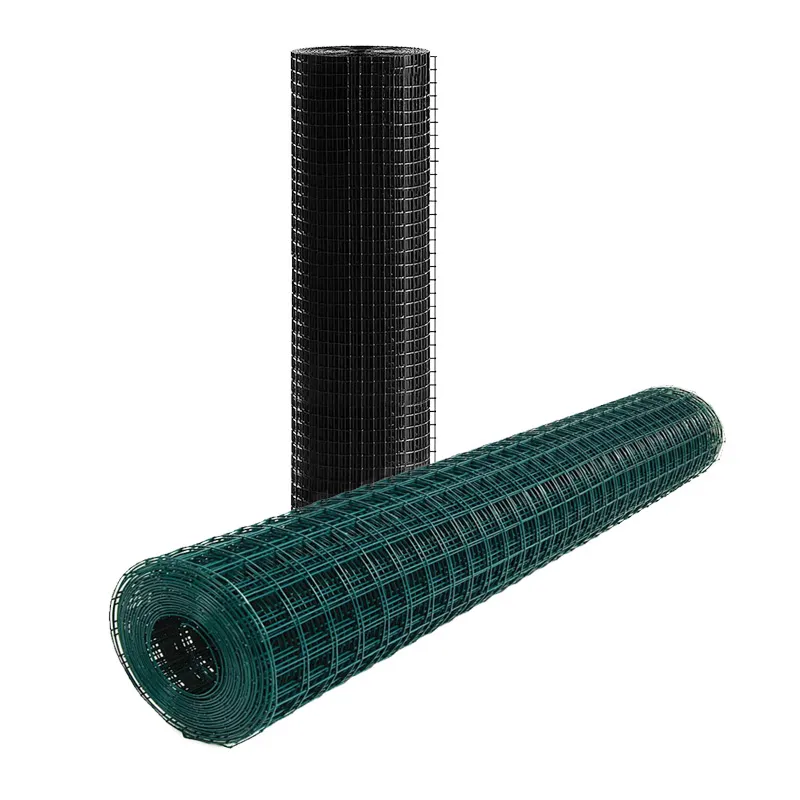

Wire mesh is a grid-like material made from interwoven wires, creating a robust and versatile structure. The term gauge refers to the thickness of the wire, with a lower gauge number indicating a thicker wire. A 10% gauge wire typically refers to wires that are about 0.10 inches in diameter. This specific thickness strikes a balance between strength and flexibility, making it suitable for various purposes. The mesh is commonly used in construction, fencing, and as reinforcement materials in concrete.

The Manufacturing Process

Factories producing 10% gauge wire mesh operate through a systematic process that ensures efficiency and high-quality output. The production begins with the selection of raw materials, usually high-quality steel wire. The chosen wire undergoes a thorough inspection to ensure it meets the required standards.

Once the raw materials are verified, they are fed into a wire drawing machine, which stretches and reduces the diameter of the wire to the desired gauge. This process strengthens the wire while making it easier to manage and weave. After drawing, the wire is cut into specific lengths geared toward the factory's mesh manufacturing machinery.

The weaving process involves mechanisms that interlace the wires to create the mesh pattern. This process can be adjusted to produce various mesh sizes and shapes, catering to diverse client requirements. The final product is then subjected to quality control checks to ensure it meets industry standards for strength, flexibility, and durability.

Applications of 10% Gauge Wire Mesh

10 gauge wire mesh factories

10% gauge wire mesh boasts a wide array of applications across different industries. In construction, it is primarily used for reinforcing concrete structures. When embedded in concrete, it helps distribute stress evenly, reducing the risk of cracking and structural failure. This is particularly crucial in areas that experience seismic activity or heavy loads.

Moreover, 10% gauge wire mesh is often used in creating safety barriers. Its robust structure is ideal for fencing applications, including residential, commercial, and agricultural settings. It provides security while allowing visibility and airflow.

In the manufacturing industry, this wire mesh serves multiple purposes, including filtration, sieving, and screening. Industries such as food processing, pharmaceuticals, and mining utilize 10% gauge wire mesh for its fine yet sturdy nature, which aids in the efficient processing of materials.

Benefits of 10% Gauge Wire Mesh

The advantages of using 10% gauge wire mesh are manifold. Firstly, its strength and durability make it a reliable choice for construction and industrial applications. Secondly, the flexibility in design and specifications allows manufacturers to customize mesh types to fit unique project requirements.

Additionally, wire mesh is often cost-effective. The materials and manufacturing processes are designed for efficiency, which can translate into lower costs for end users. Furthermore, the longevity of wire mesh materials means that they require less frequent replacement, leading to savings over time.

Conclusion

10% gauge wire mesh factories play an essential role in supplying a material that underpins many facets of modern construction and manufacturing. From its robust production processes to its diverse applications, wire mesh continues to prove its worth as a fundamental component in ensuring structural integrity and safety. As industries evolve and the demand for high-quality materials increases, the significance of wire mesh, particularly the 10% gauge variety, remains steadfastly important. Understanding this material and its production not only highlights its utility but also its impact on construction and manufacturing standards across the globe.

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025