-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Oct . 21, 2024 20:06 Back to list

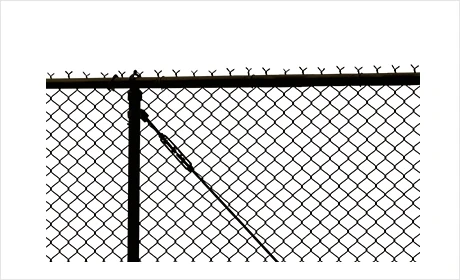

Top Manufacturers of 12.5% Gauge Barbed Wire for Quality Fencing Solutions

Understanding 12.5% Gauge Barb Wire An Overview of Its Manufacturing and Applications

Barb wire, often referred to as barbed wire, has been a vital component in agricultural fencing and security installations since its invention in the late 19th century. Among the numerous variations of this essential product, 12.5% gauge barb wire stands out for its unique characteristics and widespread use. This article explores what makes 12.5% gauge barb wire an ideal choice for various applications, focusing on its specifications, manufacturing process, and benefits.

What is 12.5% Gauge Barb Wire?

The term gauge in barb wire refers to its thickness; specifically, a lower gauge number indicates a thicker wire. The 12.5% gauge barb wire has a diameter of approximately 0.095 inches or about 2.41 mm. This thickness provides a balance between sturdiness and flexibility, making it suitable for various fencing needs. The barb wire is typically spaced along the wire at regular intervals, featuring sharp points designed to deter livestock and intruders from crossing.

Manufacturing Process

The manufacturing of 12.5% gauge barb wire involves several key steps

1. Wire Drawing The process begins with drawing wire from raw materials, typically steel or galvanized steel, which is then shaped and stretched to achieve the desired gauge thickness. This wire is often coated with zinc to enhance its corrosion resistance.

2. Barbing Once the wire reaches the correct thickness, the next step involves adding barbs. This is achieved by twisting additional wire around the main line at spaced intervals. The method of barbing can vary, but most manufacturers employ advanced machinery to ensure consistency in spacing and barb shape.

3. Coating To further increase the durability and lifespan of the barb wire, many manufacturers apply protective coatings. These coatings, often made of galvanized zinc or polymer materials, protect the wire from rust and degradation caused by environmental factors.

4. Quality Control Post-manufacture, the barb wire undergoes rigorous quality control inspections. This ensures that it meets industry standards for strength, flexibility, and barbing quality. Final products are often tested for tensile strength and resistance to deformation.

12.5 gauge barb wire manufacturer

5. Packaging and Distribution The final stage involves winding the finished barb wire onto spools or coils for ease of transportation and installation. Manufacturers prioritize ensuring that the product is well-packaged to prevent damage during shipping.

Applications and Benefits

The versatility of 12.5% gauge barb wire lends itself to numerous applications

- Agricultural Fencing Farmers commonly use this type of wire to contain livestock and protect crops. Its robust design can withstand the rough treatment often experienced in agricultural settings.

- Security Fencing Many facilities and properties utilize 12.5% gauge barb wire as a deterrent against intruders. Its sharp barbs can effectively create barriers that prevent unauthorized access.

- Construction Sites Contractors often deploy this fencing as temporary barriers around construction sites, safeguarding equipment and materials.

- Perimeter Protection To enhance security, 12.5% gauge barb wire is often installed atop walls or fences, providing an additional layer of protection.

Conclusion

12.5% gauge barb wire is a testament to the enduring and practical application of barbed wire technology. Its rigorous manufacturing process, characterized by quality control and innovative techniques, equips it to serve varied industries effectively. From farming to security applications, the robustness and reliability of this gauge make it a preferred choice among manufacturers and consumers alike. As we continue to innovate and find new uses for this age-old invention, the significance of barb wire remains unparalleled in ensuring safety and security across various environments.

-

Smart AI Fence Solutions with GPT-4 Turbo | Secure & Fast

NewsAug.02,2025

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025