-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Jan . 23, 2025 05:40 Back to list

Steel Grating

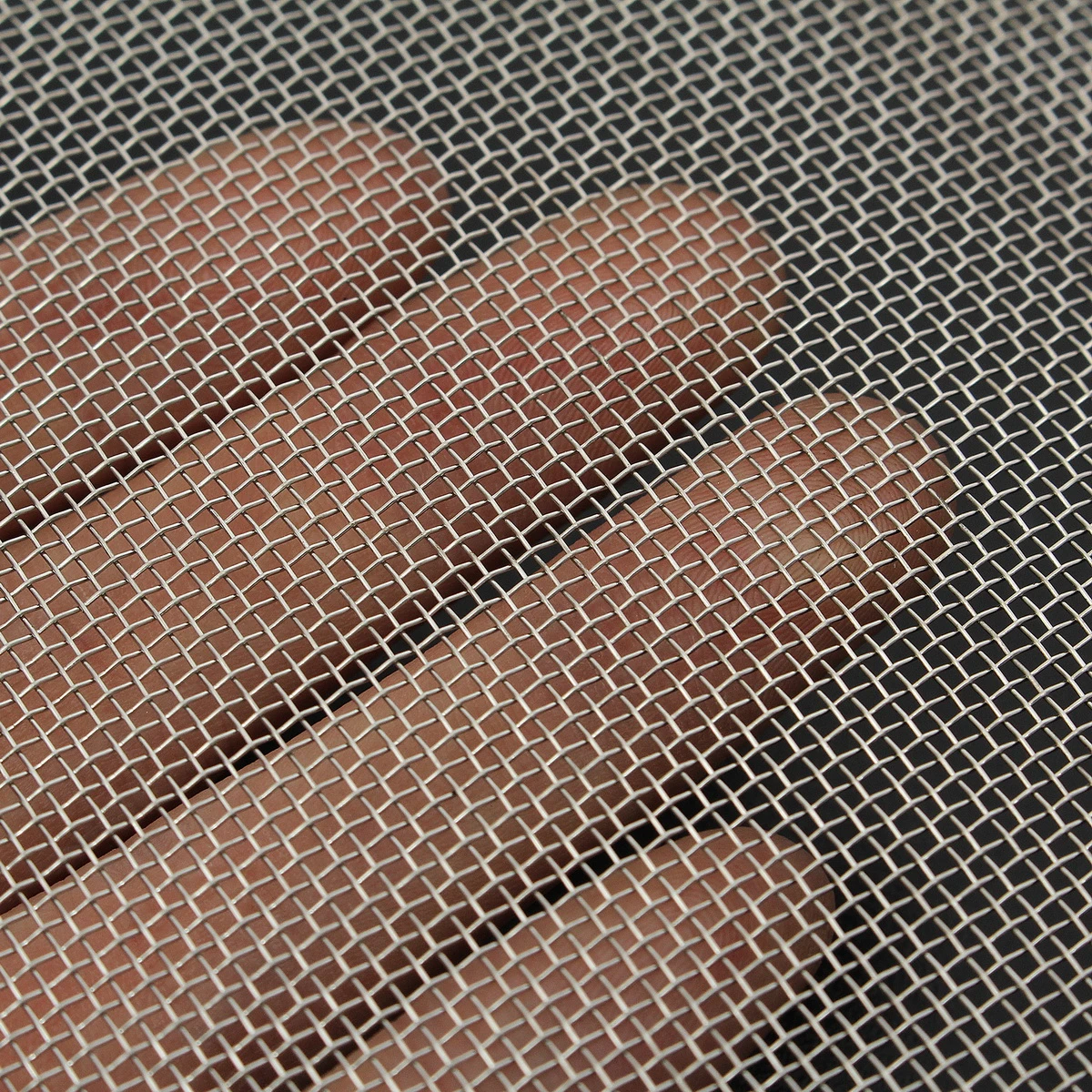

When embarking on a project that requires robust and reliable materials, choosing the right gauge of galvanized steel wire becomes a pivotal decision. For those in the know, the 12 gauge galvanized steel wire stands out as a superior choice, offering a unique blend of strength, durability, and versatility that meets both industrial and domestic demands.

Trustworthiness is perhaps the most significant attribute when considering materials for critical applications. In a case study involving a wildlife reserve, the 12 gauge wire was utilized to construct perimeter fencing, serving as a secure barrier without harming the aesthetics of the natural landscape. Over several years, reports of breaches were virtually nonexistent, illustrating the wire’s dependability. This trustworthiness stems from its consistent performance over a wide range of applications, including secure fencing, baling, and even art installations. The versatility of 12 gauge galvanized steel wire extends to creative enterprises as well. Artists and sculptors often seek materials that offer both strength and ease of manipulation. This wire gauge provides the perfect medium, allowing for the creation of intricate designs that are both resilient and aesthetically pleasing. Its malleability means artists can shape their vision with precision without compromising the structural integrity of their pieces. Moreover, for those engaged in DIY projects or agricultural endeavors, this wire is invaluable. Whether creating a trellis for climbing plants or reinforcing a chicken coop, the 12 gauge wire offers peace of mind—its strength ensures safety and stability, while the galvanization prevents rust, making maintenance minimal. To sum up, the 12 gauge galvanized steel wire is a quintessential choice for anyone seeking reliability coupled with versatility. Its broad application spectrum, from heavy-duty industrial uses to delicate artistic creations, showcases its adaptability. The professional endorsement, technical backing, and positive experiential outcomes solidify its role as a trusted material. For any project demanding strength, longevity, and resistance to environmental challenges, few materials measure up as effectively as the 12 gauge galvanized steel wire.

Trustworthiness is perhaps the most significant attribute when considering materials for critical applications. In a case study involving a wildlife reserve, the 12 gauge wire was utilized to construct perimeter fencing, serving as a secure barrier without harming the aesthetics of the natural landscape. Over several years, reports of breaches were virtually nonexistent, illustrating the wire’s dependability. This trustworthiness stems from its consistent performance over a wide range of applications, including secure fencing, baling, and even art installations. The versatility of 12 gauge galvanized steel wire extends to creative enterprises as well. Artists and sculptors often seek materials that offer both strength and ease of manipulation. This wire gauge provides the perfect medium, allowing for the creation of intricate designs that are both resilient and aesthetically pleasing. Its malleability means artists can shape their vision with precision without compromising the structural integrity of their pieces. Moreover, for those engaged in DIY projects or agricultural endeavors, this wire is invaluable. Whether creating a trellis for climbing plants or reinforcing a chicken coop, the 12 gauge wire offers peace of mind—its strength ensures safety and stability, while the galvanization prevents rust, making maintenance minimal. To sum up, the 12 gauge galvanized steel wire is a quintessential choice for anyone seeking reliability coupled with versatility. Its broad application spectrum, from heavy-duty industrial uses to delicate artistic creations, showcases its adaptability. The professional endorsement, technical backing, and positive experiential outcomes solidify its role as a trusted material. For any project demanding strength, longevity, and resistance to environmental challenges, few materials measure up as effectively as the 12 gauge galvanized steel wire.

Next:

Latest news

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025