-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Dec . 11, 2024 09:28 Back to list

Production Processes and Quality Standards in Annealed Wire Manufacturing Industry

The Role of Annealed Wire Factories in Modern Manufacturing

Annealed wire factories play a crucial role in the manufacturing industry by producing wire that has undergone a specific heat treatment process known as annealing. This process involves heating the wire to a high temperature and then allowing it to cool slowly. The primary goal of annealing is to relieve internal stresses, improve ductility, and enhance the overall mechanical properties of the wire. This article delves into the significance of annealed wire factories, their processes, products, and their impact on various industries.

What is Annealing?

Annealing is a metallurgical process that enhances the properties of metals by altering their microstructure. In the case of wire, the annealing process enables the metal to become softer and more workable. This is particularly important for applications that require high flexibility and strength, such as electrical wiring, construction materials, and automotive components. The gradual cooling phase of annealing helps prevent the formation of brittle structures, which can lead to failure under stress.

Importance of Annealed Wire

The wire produced by these factories is versatile, finding applications in numerous fields, including construction, electronics, automotive manufacturing, and more. Annealed wire is especially prized in electrical applications, where its superior ductility allows it to be bent and shaped without breaking. This is crucial for wiring systems that need to fit within confined spaces or need to curve around obstacles.

In construction, annealed wire is often used in reinforcing concrete structures, providing the tensile strength necessary for stability. The soft nature of annealed wire also makes it easier to work with, as it can be easily twisted, tied, or shaped according to specific construction requirements.

The Annealing Process

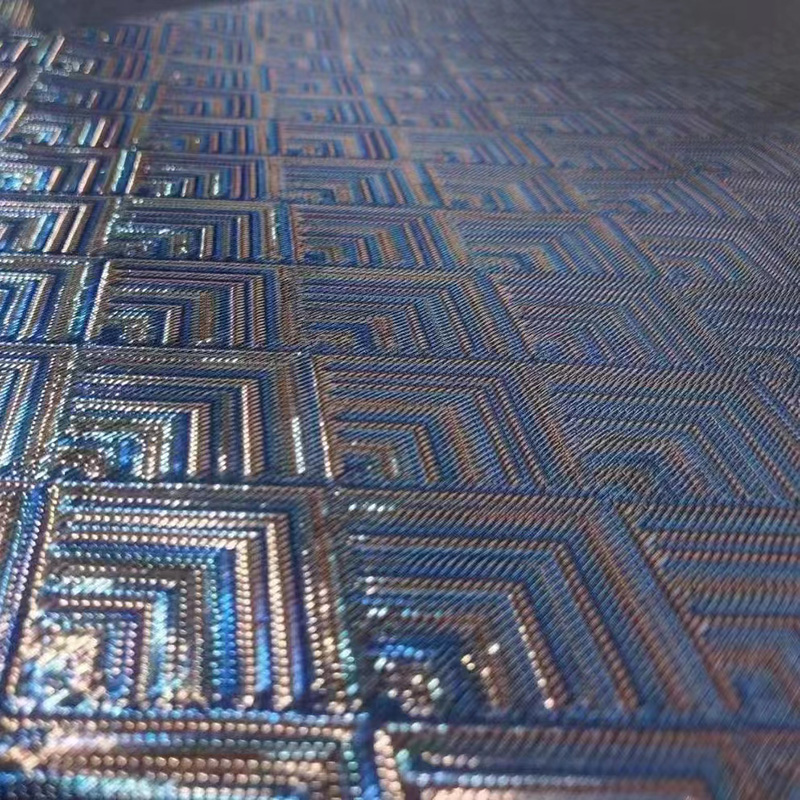

annealed wire factories

The manufacturing process in an annealed wire factory typically involves several stages. First, raw materials—often in the form of coils of wire—are sourced. These wires are usually made from various metals, including copper, steel, and aluminum, each of which has distinct properties and applications.

Once the raw wire is prepared, it is heated in a controlled environment to achieve the desired temperature. The annealing temperature depends on the type of metal and its initial state. For example, copper requires a different temperature range than steel. This precise control is essential to ensure uniformity in the final product.

After reaching the required temperature, the wire is held for a predetermined amount of time, allowing its particles to rearrange and relax internal stresses. Subsequently, the wire is cooled slowly, which further ensures optimal mechanical properties. The final step involves coiling or cutting the wire to specific lengths, ready for distribution to various industries.

Technology and Innovation

Modern annealed wire factories leverage advanced technology to improve efficiency and product quality. Automation plays a vital role in streamlining processes and minimizing human error. Additionally, modern factories are increasingly turning to digital monitoring systems that allow for real-time tracking of temperature and quality metrics. This not only ensures consistency but also enhances safety by allowing for immediate adjustments to the annealing process.

Moreover, sustainable practices are becoming integral in the operations of these factories. Many are implementing recycling systems for metal waste and exploring eco-friendly energy sources to power their operations. This commitment to sustainability is becoming increasingly valuable in today's environmentally conscious marketplace.

Conclusion

Annealed wire factories are indispensable in the modern manufacturing landscape, providing essential products that support a wide range of industries. Through the careful application of annealing processes, these factories ensure that wire is not only functional but also possesses the structural integrity required for demanding applications. As technology advances and sustainability becomes a priority, the role of annealed wire factories will continue to evolve, meeting the growing needs of the global market. Their contribution to industry efficiency and innovation will undoubtedly play a significant role in shaping the future of manufacturing.

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025