-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Sep . 19, 2024 05:07 Back to list

bird cage wire panels factory

Understanding Bird Cage Wire Panels A Deep Dive into the Factory Production

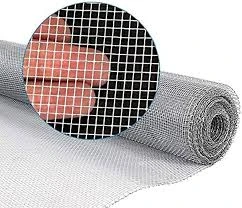

Bird cage wire panels are essential components for creating secure and comfortable habitats for pet birds. These panels are designed to provide both safety and ventilation while allowing birds to interact with their environment. The production of these panels takes place in specialized factories where attention to detail and quality control are paramount.

Understanding Bird Cage Wire Panels A Deep Dive into the Factory Production

Once the materials are in place, the process moves to wire formation. The selected wires are cut into specific lengths and then subjected to various treatments. This often includes processes like galvanizing or powder coating, which not only enhance the aesthetics of the panels but also provide additional protection against rust and weather conditions, thereby prolonging the lifespan of the bird cage.

bird cage wire panels factory

Following the treatment, the wires are shaped into the desired grid patterns that define the structure of the panels. This is a crucial step since the spacing between the wires must be carefully designed to prevent the escape of birds while allowing for proper visibility and ventilation. Factories typically use advanced machinery that can precisely position and weld the wires together, ensuring consistency in each panel produced.

Quality control is a critical aspect of the manufacturing process. After the panels are assembled, they undergo rigorous inspection procedures to check for defects, strength, and safety. Any panel that does not meet the stringent quality standards is discarded or reworked, ensuring that only the best products reach the market. This commitment to quality not only protects the birds but also builds trust with consumers who rely on these products for their pets' well-being.

In addition to production techniques, many factories are now focusing on sustainable practices. This includes recycling scrap metal from the production process and using eco-friendly materials whenever possible. By adopting these practices, manufacturers can reduce their environmental impact while still producing high-quality bird cage wire panels.

Ultimately, the factory production of bird cage wire panels combines advanced technology, skilled craftsmanship, and a dedication to quality. Consumers can feel confident knowing that their purchase is backed by careful planning and execution. Whether for personal enjoyment or as part of a commercial endeavor, these panels play a vital role in providing a safe and engaging environment for birds, contributing to their health and happiness. With ongoing advancements in manufacturing and a focus on sustainability, the future of bird cage wire panels looks promising.

-

Smart AI Fence Solutions with GPT-4 Turbo | Secure & Fast

NewsAug.02,2025

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025