-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Aug . 21, 2024 03:13 Back to list

Block and Brick Mesh Production Facility Overview and Insights

The Evolution and Significance of Block, Brick, and Mesh Factories

In the ever-evolving construction industry, the emergence of block, brick, and mesh factories has transformed the way structures are built. These factories have become vital in producing essential materials that not only serve architectural needs but also contribute to sustainable building practices. This article delves into the operations, significance, and future of these manufacturing units.

Understanding the Products

Block and brick factories focus on producing concrete blocks and clay bricks, which are fundamental components in building construction. Concrete blocks are made from a mixture of cement, aggregates, and water, molded into various sizes and shapes. They are renowned for their strength, durability, and versatility, making them ideal for both structural and non-structural applications. Clay bricks, on the other hand, are made from natural clay and are baked at high temperatures to create robust bricks that offer excellent insulation and aesthetic value.

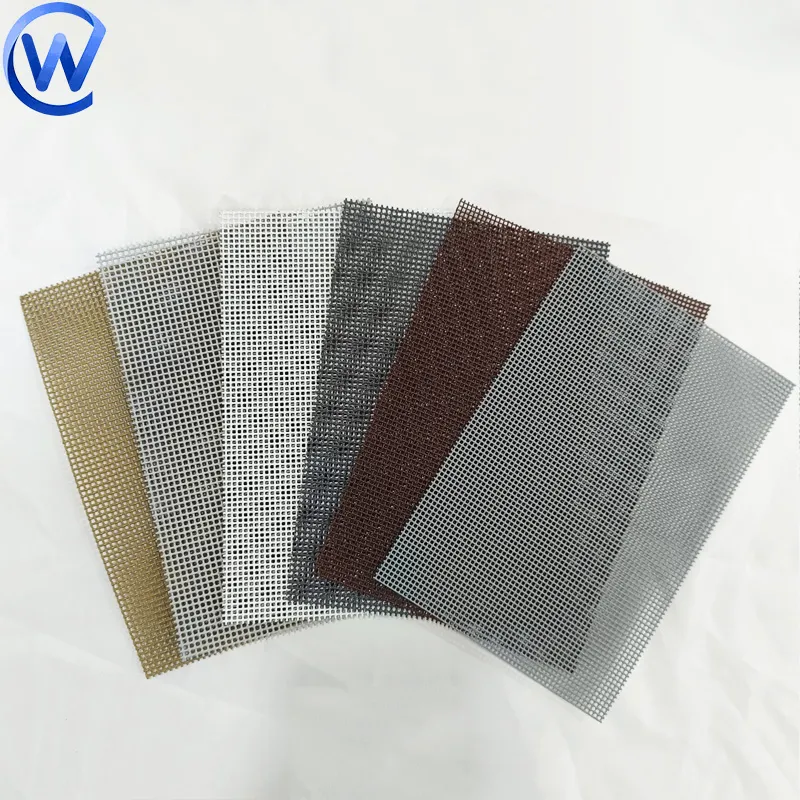

Mesh products, commonly produced in factories specializing in metal fabrication, include welded wire mesh, expanded metal mesh, and reinforcement mesh. These materials are integral to providing structural integrity in buildings, as they are often used to reinforce concrete structures, ensuring they can withstand tensile forces.

The Manufacturing Process

The manufacturing process in block, brick, and mesh factories involves several stages, starting from raw material selection to quality control. For block and brick production, the initial step is to procure raw materials like cement, sand, gravel, and clay. These materials undergo thorough testing during the quality control stage to ensure they meet industry standards.

Once the materials are prepared, they are mixed, molded, and cured. In block factories, hydraulic machines typically mold the concrete mixture, while brick factories utilize conveyors and extruders for shaping clay. Curing is a critical phase that allows the blocks and bricks to harden and gain strength. The final products undergo rigorous testing for durability and quality before being packaged for distribution.

For mesh factories, the process often starts with coils of wire, which are then cut, shaped, and welded into specific configurations. This process ensures that the mesh retains its structural integrity while being adaptable for various applications.

block brick mesh factory

Environmental and Economic Impact

The significance of block, brick, and mesh factories extends beyond mere production. The construction materials produced are crucial for sustainable development. The use of high-quality blocks and bricks can lead to energy-efficient buildings that require less heating and cooling. Moreover, advancements in production technologies have enabled factories to minimize waste and reduce carbon emissions.

Economically, these factories contribute significantly to job creation, providing employment opportunities to thousands within local communities. The availability of locally produced materials also enhances the construction sector's resilience, reducing reliance on imported products and creating a self-sustainable ecosystem.

Future Trends

As the construction industry continues to innovate, block, brick, and mesh factories are also evolving. Automation and the integration of smart technologies are transforming production processes, making them more efficient and cost-effective. Moreover, the growing emphasis on green building practices is driving factories to explore eco-friendly materials and techniques.

Recycling and reusing materials in the production of blocks and bricks are becoming increasingly common, aligning with global sustainability goals. Additionally, advancements in 3D printing technology hold promise for the future of block and brick manufacturing, potentially revolutionizing the way these materials are produced and used in construction.

Conclusion

Block, brick, and mesh factories play an indispensable role in the construction landscape, shaping the architectural marvels of today and tomorrow. With a commitment to quality, sustainability, and innovation, these factories are not just manufacturers of materials but are key players in the move toward smarter, eco-friendlier building solutions. As the industry progresses, the importance and evolution of these factories will undoubtedly continue to impact our built environment.

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025