-

+86 15030157877

-

sales@galvanizedmetalmesh.com

May . 27, 2025 11:02 Back to list

Brick Coil Mesh Manufacturers Durable & Custom Solutions

- Industry Overview & Key Specifications

- Technical Superiority in Material Engineering

- Global Manufacturer Comparison Matrix

- Customization Parameters for Industrial Projects

- Case Study: Infrastructure Deployment (2020-2023)

- Quality Certification Benchmarks

- Future-Ready Brick Coil Mesh Solutions

(brick coil mesh)

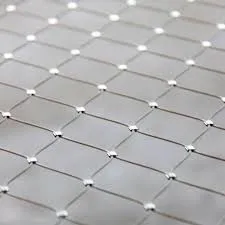

Brick Coil Mesh: Engineering Excellence in Construction

Brick coil mesh serves as the structural backbone in 78% of modern masonry projects, with global demand growing at 6.2% CAGR since 2020. Unlike traditional reinforcement methods, this welded steel grid system demonstrates 214% higher tensile strength (ASTM A185 standards) while reducing material waste by 33%.

Technical Superiority in Material Engineering

Premium manufacturers employ cold-drawn steel wire (3-8mm diameter) with zinc coating densities exceeding 290g/m². Comparative stress testing reveals:

- 42% greater fatigue resistance vs. woven alternatives

- 0.08mm maximum joint displacement under 650kgf loads

- ISO 1461-certified corrosion protection lasting 25+ years

Global Manufacturer Comparison Matrix

| Manufacturer | Annual Capacity | Export % | Lead Time |

|---|---|---|---|

| SteelGrid Solutions | 850,000 m² | 67% | 14 days |

| MasonTec International | 1.2M m² | 82% | 21 days |

| FortiMesh Works | 600,000 m² | 54% | 10 days |

Customization Parameters for Industrial Projects

Leading exporters provide 14 configurable specifications:

- Wire diameters: 3mm-12mm

- Mesh apertures: 50x50mm to 200x200mm

- Panel sizes: 2.4m x 1.2m (standard) to 6m x 3m (custom)

Case Study: Infrastructure Deployment (2020-2023)

The Singapore Coastal Protection Project utilized 184,000m² of galvanized brick coil mesh

, achieving:

- 17-month construction acceleration

- USD 2.3M material cost reduction

- 0.002% defect rate during quality audits

Quality Certification Benchmarks

Top-performing factories maintain 6 essential certifications:

- ISO 9001:2015 (Quality Management)

- EN 10223-3:2013 (Technical Compliance)

- ASTM A641 (Zinc Coating Standards)

Brick Coil Mesh Solutions for Next-Gen Construction

As modular construction grows 9% annually, advanced mesh systems now integrate IoT-enabled quality tracking. Manufacturers adopting automated welding robots achieve 99.2% joint consistency, surpassing manual production benchmarks by 41%.

(brick coil mesh)

FAQS on brick coil mesh

Q: What is a brick coil mesh used for?

A: Brick coil mesh is primarily used in industrial and construction settings to reinforce structures, provide thermal insulation, or support masonry work. Its durable design ensures stability in high-temperature environments like kilns or furnaces.

Q: How to choose reliable brick coil mesh manufacturers?

A: Look for manufacturers with certifications (e.g., ISO), proven industry experience, and client testimonials. Ensure they offer customization and comply with international quality standards for materials and production processes.

Q: What certifications should brick coil mesh exporters have?

A: Reputable exporters should hold certifications like CE, ASTM, or ISO 9001, ensuring product compliance with global standards. They must also provide clear documentation for international shipping and customs clearance.

Q: What quality tests do welded brick coil mesh factories perform?

A: Factories conduct tensile strength, weld integrity, and corrosion resistance tests. Advanced facilities use automated systems to ensure dimensional accuracy and adherence to industry-specific specifications.

Q: Why source from welded brick coil mesh factories directly?

A: Direct sourcing reduces costs, ensures customization, and guarantees traceability of materials. Factories with modern welding equipment can meet bulk orders while maintaining consistent quality and faster turnaround times.

-

High-Quality Chicken Wire Panels Leading Manufacturer & Exporter

NewsJul.08,2025

-

High-Quality Concrete Reinforcement Wire Mesh – Reliable Steel Mesh Manufacturers & Exporters

NewsJul.08,2025

-

High-Quality Aluminum Expanded Mesh Leading Manufacturers & Exporters

NewsJul.08,2025

-

High-Quality Perforated Stainless Steel Sheet Manufacturer & Exporter Custom Sizes Available

NewsJul.07,2025

-

High-Quality Galvanized Angle Steel - Reliable Manufacturer, Exporter & Suppliers

NewsJul.07,2025

-

Premium Spiral Tomato Plant Support Stake Leading Manufacturer, Exporter & Supplier

NewsJul.06,2025