-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Nov . 08, 2024 20:07 Back to list

brick coil mesh exporter

The Rise of Brick Coil Mesh Exporters A New Era in Construction Materials

In an ever-evolving global market, the construction industry continually seeks innovative materials that can enhance building practices while ensuring sustainability and efficiency. One such innovation is the brick coil mesh, a versatile and durable solution gaining traction among builders and architects. As the demand for this product grows, brick coil mesh exporters are now playing a crucial role in international trade, facilitating access to this essential construction material worldwide.

What is Brick Coil Mesh?

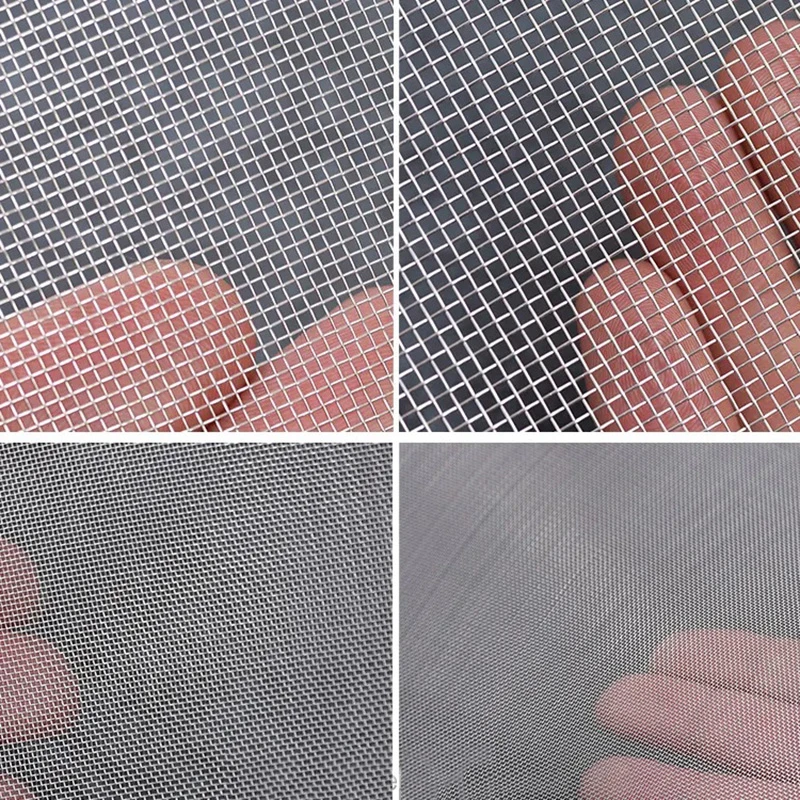

Brick coil mesh is a specialized construction product made from high-quality steel that is designed to improve the structural integrity of buildings. It is typically used to reinforce brickwork, providing additional support and stability. The mesh is manufactured in coils, making it easy to handle and transport, which is advantageous for large construction projects. Its unique design allows for excellent adherence to mortar, enhancing the overall durability of brick structures.

Benefits of Brick Coil Mesh

The advantages of using brick coil mesh are manifold. Firstly, it significantly improves the strength of brick walls, reducing the risk of cracking and other structural issues over time. This can lead to lower maintenance costs for property owners and increased lifespan for buildings.

Secondly, its lightweight nature makes it easier to install, thereby reducing labor costs and time on-site. Furthermore, the mesh can be custom-made to suit various architectural designs, making it a versatile option for builders looking to implement specific aesthetic elements.

Another significant advantage is its sustainability. Many brick coil mesh exporters are now focusing on eco-friendly production processes, utilizing recycled materials and minimizing waste. This aligns with the growing trend in the construction industry towards sustainable building practices, making brick coil mesh an attractive option for environmentally-conscious projects.

brick coil mesh exporter

The Role of Exporters

As international demand for brick coil mesh rises, exporters are becoming key players in this niche market. They play a vital role in ensuring that high-quality products reach builders and contractors across the globe. Exporters facilitate this process by handling logistics, maintaining quality control, and ensuring compliance with various international standards.

Many brick coil mesh exporters have established themselves in regions with strong construction sectors, such as Southeast Asia, Europe, and North America. They often partner with local manufacturers to streamline production and distribution, ensuring that clients receive the best products tailored to their specific needs.

Challenges in the Export Market

While the future looks promising for brick coil mesh exporters, they also face several challenges. Fluctuations in raw material prices, changing trade regulations, and competition from alternative construction materials can impact profit margins and market share. Additionally, exporters must navigate the complexities of international shipping logistics, which can include tariffs, customs regulations, and varying quality standards across countries.

To overcome these challenges, many exporters are investing in technology and infrastructure to enhance operational efficiencies. Advanced inventory management systems, predictive analytics for demand forecasting, and robust supply chain management practices are becoming increasingly important in maintaining competitiveness in the global market.

Conclusion

The growth of brick coil mesh and its exporters represents a significant shift in the construction materials landscape. As builders and architects continue to seek sustainable, efficient solutions, the demand for brick coil mesh is likely to grow. Brick coil mesh exporters play a crucial role in this transition, ensuring that quality products are available worldwide. Through innovation and strategic partnerships, the future of brick coil mesh in the construction industry looks bright, promising enhanced structural integrity and sustainability for buildings around the globe.

-

Smart AI Fence Solutions with GPT-4 Turbo | Secure & Fast

NewsAug.02,2025

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025