-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Nov . 13, 2024 02:57 Back to list

catwalk steel grating manufacturers

The Role of Catwalk Steel Grating Manufacturers in Industrial Safety and Efficiency

In the industrial landscape, safety and efficiency are paramount, especially in environments such as factories, warehouses, and construction sites. One crucial component that contributes significantly to these factors is steel grating, particularly catwalk steel grating. Manufacturers who specialize in producing this vital infrastructure play a key role in ensuring workplaces are both secure and functional.

Understanding Catwalk Steel Grating

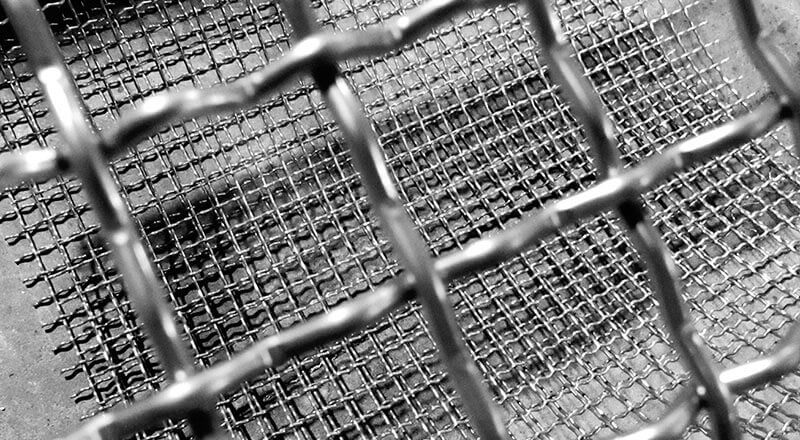

Catwalk steel grating refers to a type of flooring composed of a grid of metal bars, which allows for the passage of light and air while providing a sturdy walking surface. Typically used in elevated walkways, platforms, and scaffolds, this type of grating is designed for heavy-duty applications, which require materials that can support substantial loads while also withstanding harsh environmental conditions.

The design of catwalk steel grating usually includes a variety of openings which enable drainage, minimizing the risk of water accumulation, and thereby reducing slip hazards. Additionally, the open design offers visibility from below, contributing to overall site safety by allowing for the quick identification of potential hazards.

The Manufacturing Process

Catwalk steel grating manufacturers utilize a variety of materials, primarily steel, due to its strength and durability. The manufacturing process typically involves the following steps

1. Steel Sourcing Quality raw materials are sourced from reputable suppliers, ensuring that the grating meets industry standards for strength and reliability.

2. Cutting and Shaping The steel is cut into specific dimensions and shaped into the desired grid pattern. Advanced machinery, such as CNC routers, is often employed to achieve precise cuts and configurations.

3. Welding The components are then welded together to form a sturdy framework. This process may involve different welding techniques, depending on the grating type and application requirements.

4. Finishing After the welding process, the grating undergoes various finishing treatments, such as galvanization or powder coating. These processes enhance corrosion resistance, thereby extending the lifespan of the grating and reducing maintenance needs.

catwalk steel grating manufacturers

Benefits of Catwalk Steel Grating

The advantages of using catwalk steel grating are manifold

- Strength and Durability Steel grating can withstand significant loads and is resistant to various environmental factors, making it ideal for industrial use.

- Safety Features The slip-resistant surface combined with drainage capabilities reduces the likelihood of slips and falls, contributing to a safer work environment.

- Versatility Catwalk steel grating can be used in a variety of applications, including outdoor and indoor settings. Its adaptable nature makes it useful in many sectors, from manufacturing to food processing.

- Ease of Installation Most catwalk steel grating systems are designed for quick and easy installation, saving both time and labor costs for companies.

The Future of Catwalk Steel Grating

As industries continue to evolve, the demand for advanced safety solutions in the workplace grows. Catwalk steel grating manufacturers are increasingly focusing on innovative designs, improved materials, and sustainability. The incorporation of recyclable materials and eco-friendly finishes is likely to become more prevalent as industries aim to reduce their environmental impact.

Manufacturers are also leveraging technology, using digital tools for design and production processes, enhancing efficiency and precision. Furthermore, smart grating systems equipped with sensors to monitor load, temperature, and other factors could revolutionize industrial safety measures.

Conclusion

Catwalk steel grating manufacturers serve a critical function in ensuring the safety and efficiency of industrial workplaces. Through their commitment to quality and innovation, they not only provide essential infrastructure but also shape the future of safety solutions in various sectors. As industries continue to strive for higher safety standards, the role of these manufacturers will undoubtedly become even more significant, paving the way for safer and more efficient working environments.

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025