-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Aug . 18, 2024 13:03 Back to list

Choosing the Right Perforated Metal Manufacturer for Your Project Needs

The Role of Perforated Metal Manufacturers in Modern Industries

In today's rapidly evolving industrial landscape, perforated metal has emerged as an essential material for a multitude of applications. From architecture to automotive engineering, the versatility of perforated metal cannot be overstated. At the heart of this innovation are perforated metal manufacturers, whose expertise and craftsmanship are fundamental to the production of high-quality perforated materials.

Understanding Perforated Metal

Perforated metal is sheet metal that has been manually or mechanically punched to create a pattern of holes. These holes can vary in shape, size, and spacing, allowing for a wide range of designs and functionalities. The process typically involves using stainless steel, aluminum, brass, or other metals, making it both durable and aesthetically appealing. The resulting products can be found in diverse applications, from air filtration systems and sound control panels to architectural facades and decorative elements.

Applications Across Industries

One of the primary sectors benefitting from perforated metal is architecture. Architects and designers utilize perforated metal for facades, sunshades, and interior finishes due to its aesthetic appeal and functional benefits. Perforated sheets can control natural light, enhance ventilation, and contribute to energy efficiency. For instance, a building with a perforated facade allows for light penetration while minimizing direct heat, leading to energy savings and improved occupant comfort.

In the automotive industry, perforated metal plays a crucial role in not only aesthetics but also functionality. Manufacturers use perforated metals for grilles, heat shields, and sound dampening components. By precisely engineering hole sizes and patterns, manufacturers can tailor the acoustics and airflow characteristics of vehicles, leading to quieter, more efficient rides.

Moreover, the food and pharmaceutical industries rely on perforated metals for filtration and sanitation processes. Perforated trays and screens facilitate effective separation of materials while ensuring that hygiene standards are maintained. These applications highlight the importance of using high-quality, precision-perforated materials to meet strict regulatory requirements.

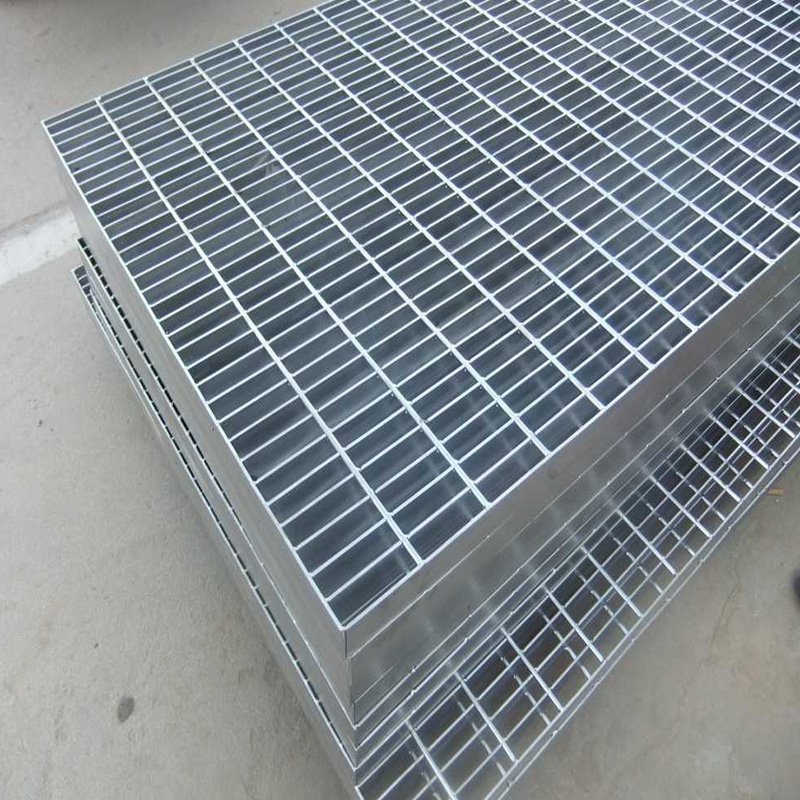

perforated metal manufacturer

The Manufacturing Process

The production of perforated metal involves several key steps, starting with the selection of appropriate raw materials. The chosen metal sheets are then subjected to a punching or laser cutting process, where holes are created according to specified designs. Once perforated, the sheets may undergo additional treatments, such as galvanization or coating, to enhance durability and corrosion resistance.

Many perforated metal manufacturers also offer customization options, allowing clients to request specific hole patterns, sizes, and finishes. This flexibility has made perforated metal an increasingly popular choice among designers and engineers seeking tailored solutions to meet their project needs.

Quality Assurance and Sustainability

High-quality perforated metal must withstand various environmental conditions and serve its intended purpose effectively. Manufacturers often implement stringent quality control measures throughout the production process to ensure that the final products meet industry standards. From raw material selection to the final inspection, quality assurance remains a cornerstone of perforated metal manufacturing.

Moreover, sustainability is becoming a critical focus in the manufacturing sector. Many perforated metal manufacturers are adopting eco-friendly practices, such as recycling scrap metal and using sustainable production methods. This commitment not only reduces waste but also appeals to environmentally conscious clients looking for sustainable construction solutions.

Conclusion

Perforated metal manufacturers play a vital role in supplying a versatile material that finds applications across numerous industries. Their ability to blend functionality with aesthetic appeal makes perforated metal an invaluable resource for architects, engineers, and designers alike. As technology advances and the demand for innovative solutions continues to grow, the impact of perforated metal and its manufacturers will remain significant in shaping the future of modern design and construction.

-

Premium Hexagonal Gabion Mesh Solutions | Durable & Eco-Friendly

NewsAug.03,2025

-

Smart AI Fence Solutions with GPT-4 Turbo | Secure & Fast

NewsAug.02,2025

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025