-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Jan . 31, 2025 05:12 Back to list

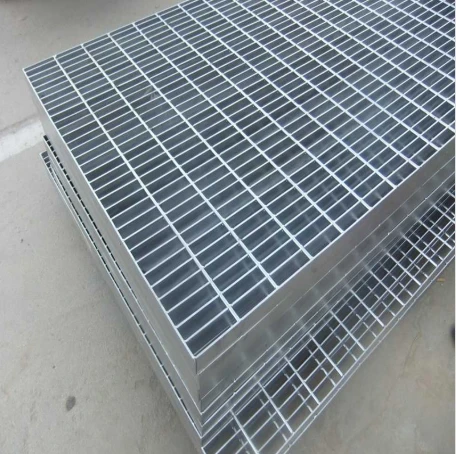

Welded Wire Mesh

In the realm of modern construction, concrete welded wire mesh emerges as an indispensable component, offering unparalleled structural integrity and versatility. As a leading solution for reinforcing concrete, this meticulously crafted product boasts not only reliability but also efficiency in application, making it a cornerstone of foundational stability across various projects.

In terms of trustworthiness, the use of concrete welded wire mesh complies with stringent industry standards and regulations. Builders and engineers worldwide rely on its consistent quality and performance, often citing documented case studies where its application has notably extended the lifespan of concrete structures. Such endorsements from industry leaders further cement its standing as a credible and reliable choice in construction reinforcement. Professionals harness concrete welded wire mesh not just for its mechanical properties but also for its versatility. The mesh is available in various sizes and specifications, allowing for customization to suit specific project requirements. This adaptability ensures that whether it's a high-rise construction or a smaller residential setup, the mesh can be tailored to optimize performance and budget. Furthermore, the environmental benefits tied to the use of welded wire mesh make it a sustainable choice. The steel used can be recycled, reducing the carbon footprint associated with its production. In an age where sustainable practices are no longer optional but necessary, choosing environmentally friendly materials like concrete welded wire mesh contributes positively to ecological conservation efforts. In conclusion, for construction professionals aiming to achieve excellence in structural projects, concrete welded wire mesh stands out as a premier choice. Its blend of strength, reliability, and adaptability makes it a preferred option for ensuring durability and safety in concrete structures. As a product backed by expertise and a track record of authoritative success, it continues to set the standard for construction reinforcement in the modern age.

In terms of trustworthiness, the use of concrete welded wire mesh complies with stringent industry standards and regulations. Builders and engineers worldwide rely on its consistent quality and performance, often citing documented case studies where its application has notably extended the lifespan of concrete structures. Such endorsements from industry leaders further cement its standing as a credible and reliable choice in construction reinforcement. Professionals harness concrete welded wire mesh not just for its mechanical properties but also for its versatility. The mesh is available in various sizes and specifications, allowing for customization to suit specific project requirements. This adaptability ensures that whether it's a high-rise construction or a smaller residential setup, the mesh can be tailored to optimize performance and budget. Furthermore, the environmental benefits tied to the use of welded wire mesh make it a sustainable choice. The steel used can be recycled, reducing the carbon footprint associated with its production. In an age where sustainable practices are no longer optional but necessary, choosing environmentally friendly materials like concrete welded wire mesh contributes positively to ecological conservation efforts. In conclusion, for construction professionals aiming to achieve excellence in structural projects, concrete welded wire mesh stands out as a premier choice. Its blend of strength, reliability, and adaptability makes it a preferred option for ensuring durability and safety in concrete structures. As a product backed by expertise and a track record of authoritative success, it continues to set the standard for construction reinforcement in the modern age.

Next:

Latest news

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025