-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Oct . 01, 2024 02:45 Back to list

Exporter of High-Quality Crimped Wire Mesh for Various Industrial Applications

Crimped Wire Mesh Exporter A Comprehensive Overview

In the ever-evolving landscape of industrial applications, crimped wire mesh has emerged as a critical component in various sectors due to its versatility and durability. From construction to agriculture, crimped wire mesh serves a plethora of functions, making it an indispensable product in many industries. As global trade continues to expand, the role of crimped wire mesh exporters becomes increasingly significant, bridging the gap between manufacturers and end-users across the world.

What is Crimped Wire Mesh?

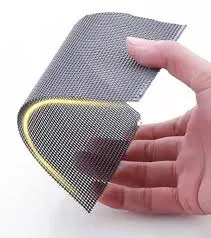

Crimped wire mesh is a type of woven mesh made from high-quality metal wires that are crimped or twisted to create a series of parallel ridges. This unique design enhances the structural integrity of the mesh, allowing it to withstand significant mechanical stress. Crimped wire mesh can be manufactured using various materials, including stainless steel, galvanized steel, and mild steel, each offering specific advantages regarding corrosion resistance, strength, and weight.

The manufacturing process of crimped wire mesh involves weaving pre-crimped wires together in a systematic pattern, creating openings in the mesh that can vary in size depending on the intended application. This adaptability makes it suitable for a wide range of uses, including filtration, support panels, fencing, and even decorative purposes.

Market Demand and Applications

The demand for crimped wire mesh continues to thrive across multiple industries. In construction, it serves as a vital reinforcement material for concrete structures and as safety barriers on construction sites. In agriculture, crimped wire mesh is commonly used for fencing, livestock enclosures, and crop protection. Additionally, the mining and mineral processing industries rely heavily on crimped wire mesh for their screening and separation processes.

Moreover, the architectural sector has begun to embrace crimped wire mesh for its aesthetic appeal

. Designers utilize it in facades, sunshades, and interior décor, showcasing its versatility beyond traditional applications. This diversification in usage has consequently fueled the growth of crimped wire mesh exporters, who cater to a broad range of customers seeking custom solutions to meet their specific needs.Role of Crimped Wire Mesh Exporters

crimped wire mesh exporter

Crimped wire mesh exporters play a crucial role in the international supply chain by facilitating the movement of this versatile product from manufacturers to global markets. They are responsible for a variety of functions, including sourcing high-quality materials, maintaining production standards, and ensuring compliance with international regulations.

One of the main challenges for exporters is navigating the complexities of global trade. Understanding tariffs, import/export regulations, and logistical requirements is essential to successfully deliver products to clients worldwide. Additionally, crimped wire mesh exporters must remain adaptable to market trends and customer requirements, often customizing their offerings to meet specific project specifications.

Effective communication is another key aspect of the exporter’s role. They must be able to educate potential buyers about the various applications and benefits of crimped wire mesh, providing guidance on selecting the right specifications for their needs. Building strong relationships with both manufacturers and customers is vital for ensuring smooth transactions and fostering long-term partnerships.

Challenges and Opportunities

While the demand for crimped wire mesh presents numerous opportunities for exporters, it is not without its challenges. Fluctuations in raw material prices can impact production costs and, consequently, pricing strategies. Additionally, the rise of regional competitors can create pressures on pricing and service delivery.

However, by leveraging advanced technologies and optimizing supply chain processes, crimped wire mesh exporters can enhance their competitiveness in the market. Investing in research and development to create innovative products can also help exporters differentiate themselves from the competition, expanding their market share.

Conclusion

In conclusion, as crimped wire mesh continues to be a vital material across various industries, the importance of proficient exporters cannot be overstated. By navigating the challenges of global trade and adapting to market demands, crimped wire mesh exporters play an essential role in connecting manufacturers with a diverse clientele. With the right strategies in place, they can open new avenues for growth while contributing to the seamless flow of this crucial commodity in the international market.

-

Smart AI Fence Solutions with GPT-4 Turbo | Secure & Fast

NewsAug.02,2025

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025