-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Jan . 20, 2025 07:30 Back to list

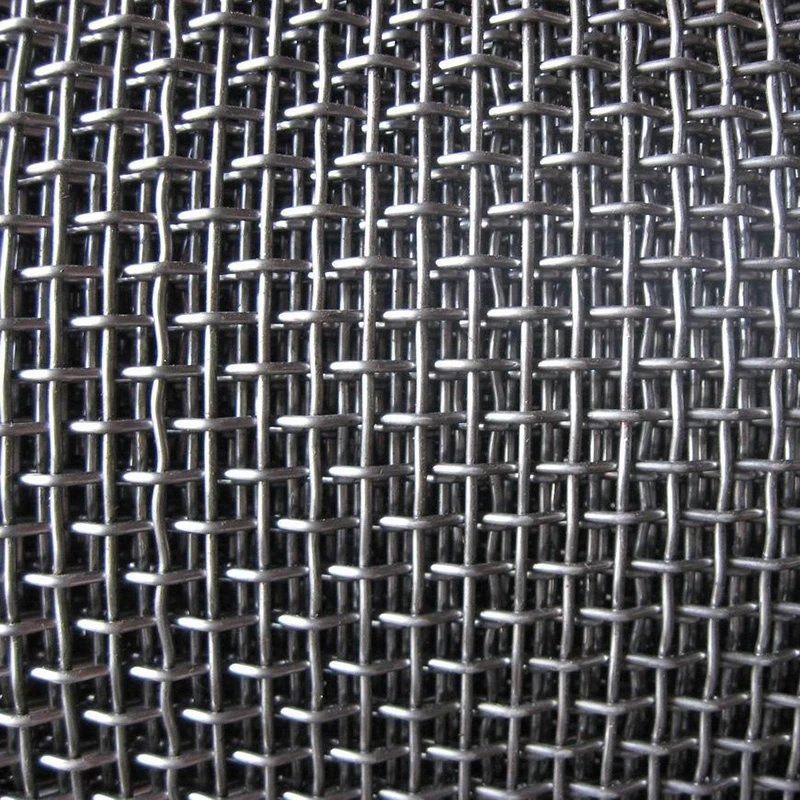

crimped woven wire mesh

Crimped woven wire mesh stands as a versatile and crucial component across various industries, offering a range of applications from industrial processing to architectural embellishments. The distinct weaving technique provides durability, stability, and adaptability, making it a preferred choice for professionals seeking reliability and efficiency in their processes.

In delivering trustworthiness, manufacturers adhere to strict quality control standards, ensuring that each batch of crimped woven wire mesh meets industry-specific requirements. Transparency in production processes facilitates confidence among end-users, who rely on the consistent quality of the mesh for their varied applications. Trust is further reinforced through comprehensive documentation available from credible manufacturers, detailing specifications, compatibility notes, and case studies demonstrating successful implementations. A real-world example highlighting the mesh's practical application involves its use in the innovative design of public spaces. Architects often utilize crimped woven wire mesh to balance functionality with aesthetic appeal in urban installations, with examples including pedestrian bridges and museum facades. The mesh delivers both structural support and artistic elegance, manifesting the possibilities that architects can explore with this material. Such projects often inspire future uses and innovations, reaffirming the importance and utility of crimped woven wire mesh in modern design. Professionals looking to integrate crimped woven wire mesh into their projects must understand its specific strengths and limitations. Prior assessments of environmental conditions and load requirements will facilitate informed decisions, ensuring the mesh meets intended performance criteria. Consulting with experts and engaging with knowledgeable suppliers will provide essential insights, helping to tailor the mesh's application to specific project needs efficiently. In conclusion, crimped woven wire mesh stands as a pillar of reliability and versatility in numerous applications. Expertise in its deployment is crucial for maximizing outcomes, whether in industrial domains or creative architectural ventures. Its broad endorsement across sectors testifies to its indispensable nature—an embodiment of durability, adaptability, and innovative potential. As industries evolve, so too will the applications of crimped woven wire mesh, promising new horizons of efficiency and beauty.

In delivering trustworthiness, manufacturers adhere to strict quality control standards, ensuring that each batch of crimped woven wire mesh meets industry-specific requirements. Transparency in production processes facilitates confidence among end-users, who rely on the consistent quality of the mesh for their varied applications. Trust is further reinforced through comprehensive documentation available from credible manufacturers, detailing specifications, compatibility notes, and case studies demonstrating successful implementations. A real-world example highlighting the mesh's practical application involves its use in the innovative design of public spaces. Architects often utilize crimped woven wire mesh to balance functionality with aesthetic appeal in urban installations, with examples including pedestrian bridges and museum facades. The mesh delivers both structural support and artistic elegance, manifesting the possibilities that architects can explore with this material. Such projects often inspire future uses and innovations, reaffirming the importance and utility of crimped woven wire mesh in modern design. Professionals looking to integrate crimped woven wire mesh into their projects must understand its specific strengths and limitations. Prior assessments of environmental conditions and load requirements will facilitate informed decisions, ensuring the mesh meets intended performance criteria. Consulting with experts and engaging with knowledgeable suppliers will provide essential insights, helping to tailor the mesh's application to specific project needs efficiently. In conclusion, crimped woven wire mesh stands as a pillar of reliability and versatility in numerous applications. Expertise in its deployment is crucial for maximizing outcomes, whether in industrial domains or creative architectural ventures. Its broad endorsement across sectors testifies to its indispensable nature—an embodiment of durability, adaptability, and innovative potential. As industries evolve, so too will the applications of crimped woven wire mesh, promising new horizons of efficiency and beauty.

Latest news

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025