-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Aug . 18, 2024 15:20 Back to list

Custom Crimped Mesh Solutions for Enhanced Durability and Versatility in Various Applications

Exploring Custom Crimped Mesh Versatility and Applications

In the world of industrial and commercial applications, the use of specialized materials often sets apart the best-performing products from the rest. One such innovative material is custom crimped mesh, a versatile solution that serves a variety of needs in different sectors. This article delves into what crimped mesh is, its production process, various applications, and the benefits it offers.

What is Custom Crimped Mesh?

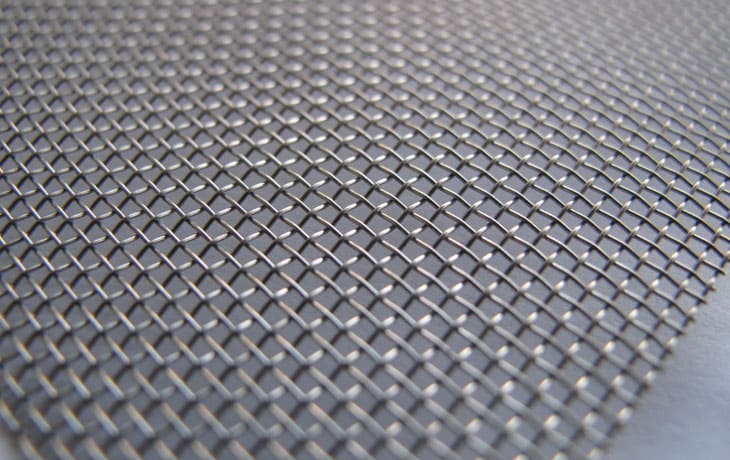

Custom crimped mesh refers to a type of wire mesh where the wires are crimped or bent in a wave-like pattern instead of being laid flat. This crimping creates a dimensional, three-dimensional structure that enhances the mesh's strength, flexibility, and overall performance. The term custom indicates that the mesh can be tailored to specific dimensions, wire gauges, and crimp patterns to meet the unique requirements of various applications.

Production Process

The production of crimped mesh involves several key steps. First, steel or other materials such as stainless steel, aluminum, or plastic are selected based on the desired characteristics of the final product. The wires are then cut to the required lengths. Once the wires are prepared, the crimping process takes place, wherein the wires are shaped into the desired crimp patterns using specialized machinery. After crimping, the wires are woven together to form the finished mesh, which is then cut to size and finished as needed—whether through coatings for corrosion resistance or treatments for enhanced durability.

Applications of Crimped Mesh

The applications of custom crimped mesh are incredibly diverse and can be found across various industries

. Here are some notable uses1. Mining and Quarrying Crimped mesh is widely used in mining operations for screening and sorting materials. Its sturdy design allows it to withstand heavy loads and abrasive conditions, making it ideal for this demanding environment.

custom crimped mesh

2. Construction In the construction industry, crimped mesh serves multiple purposes, such as reinforcing concrete or providing support for various building materials. Its customizable nature allows it to fit perfectly into construction projects of any scale.

3. Agriculture Farmers utilize crimped mesh for fencing and as protective coverings for crops. Its effective design helps keep pests out while allowing sunlight and rain to nourish plants.

4. Architecture and Design Custom crimped mesh can also serve aesthetic purposes in architecture. Its unique appearance can be used for facades, sunshades, and decorative elements in modern building designs.

5. Filtration Systems In industrial filtration applications, crimped mesh is employed for water treatment and air filtration. Its varying mesh sizes allow for effective filtering, ensuring the removal of contaminants.

Benefits of Custom Crimped Mesh

The advantages of using custom crimped mesh are numerous. Notably, its crimped design increases the mesh's tensile strength, making it more durable than flat mesh alternatives. The ability to customize dimensions and patterns means that businesses can procure exactly what they need without compromising on quality or performance. Additionally, crimped mesh is usually lightweight, which aids in transportation and installation.

Conclusion

Custom crimped mesh stands as a testament to the innovation in material design, offering both functional and aesthetic solutions across various industries. With its adaptability and durability, it demonstrates how a simple modification in material processing can lead to significant improvements in performance and application versatility. As industries continue to evolve, the demand for customized solutions like crimped mesh is likely to grow, proving that this material is pivotal in modern industrial practices.

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025