-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Jun . 24, 2024 06:00 Back to list

custom galvanized steel grating ,

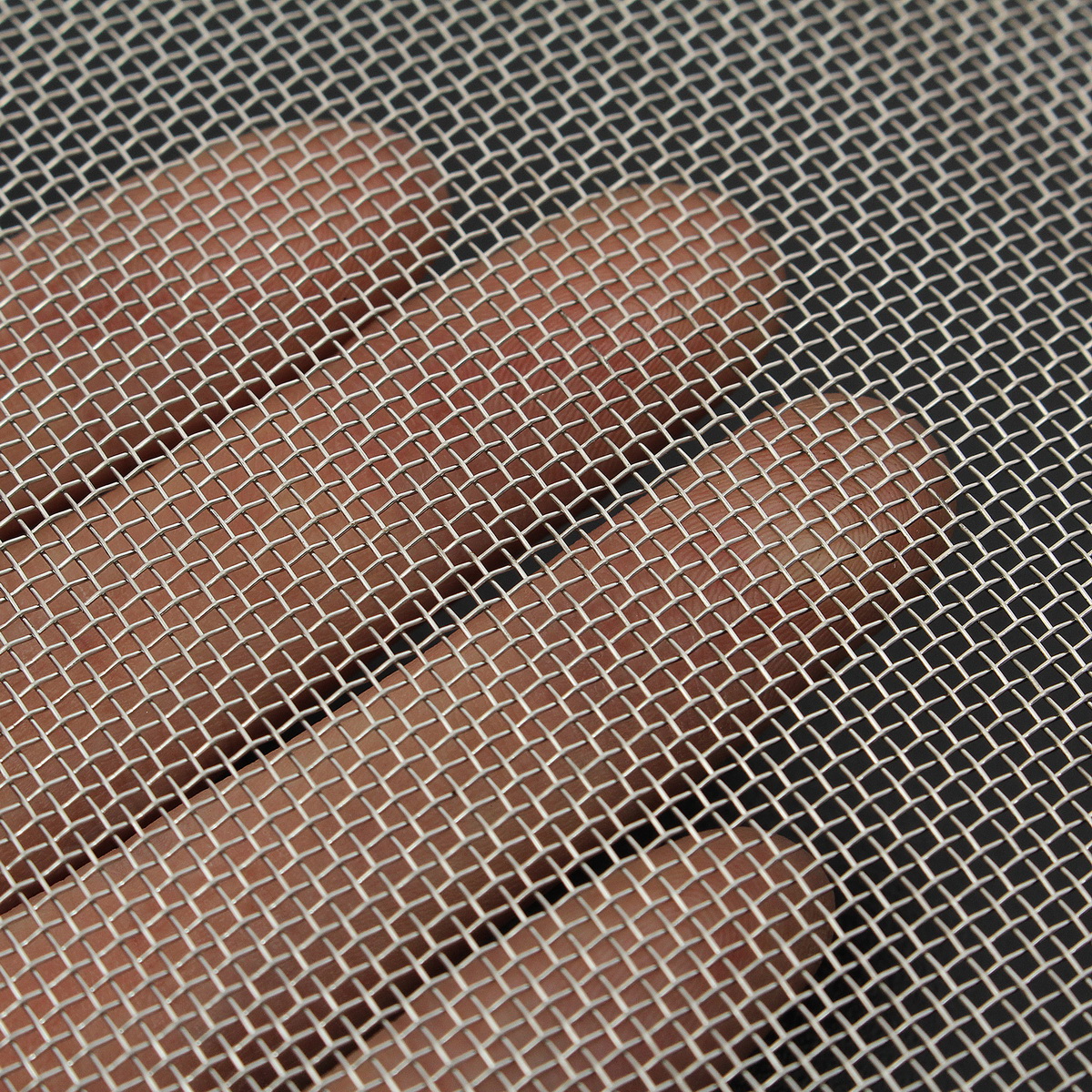

Custom Galvanized Steel Grating A Versatile and Durable Material for Various Applications

Galvanized steel grating, a popular material in the construction industry, offers numerous benefits that make it an ideal choice for various applications. This article will discuss the features, advantages, and uses of custom galvanized steel grating.

Features of Custom Galvanized Steel Grating

1. Corrosion resistance Galvanizing is a process that involves coating steel with zinc to protect it from corrosion. The zinc layer forms a barrier between the steel and the environment, preventing rust and extending the life of the grating.

2. High strength Galvanized steel grating is made from high-strength steel, which provides excellent load-bearing capacity and stability. It can withstand heavy loads and resist deformation under extreme conditions.

3. Slip resistance The raised ribs on the surface of galvanized steel grating provide excellent slip resistance, making it safer to walk on in wet or slippery environments.

4. Easy maintenance Cleaning and maintaining galvanized steel grating is relatively simple. Rinsing with water and mild detergent is usually sufficient to remove dirt and debris.

5. Customizable Custom galvanized steel grating can be designed and manufactured to meet specific requirements, such as size, shape, and load capacity. This makes it suitable for a wide range of applications.

Advantages of Custom Galvanized Steel Grating

1. Durability The combination of zinc coating and high-strength steel makes custom galvanized steel grating highly durable and long-lasting. It can withstand harsh weather conditions, chemicals, and other environmental factors.

2. Safety The slip-resistant surface and high load capacity of custom galvanized steel grating provide a safe working environment Safety The slip-resistant surface and high load capacity of custom galvanized steel grating provide a safe working environment Safety The slip-resistant surface and high load capacity of custom galvanized steel grating provide a safe working environment Safety The slip-resistant surface and high load capacity of custom galvanized steel grating provide a safe working environment

Safety The slip-resistant surface and high load capacity of custom galvanized steel grating provide a safe working environment Safety The slip-resistant surface and high load capacity of custom galvanized steel grating provide a safe working environment custom galvanized steel grating. It is commonly used in industrial floors, platforms, walkways, and ramps.

3. Cost-effective Although custom galvanized steel grating may have a higher initial cost compared to other materials, its durability and long service life can help reduce maintenance and replacement costs over time.

4. Environmental friendliness Zinc is a non-toxic and recyclable material, making custom galvanized steel grating environmentally friendly. It has a low carbon footprint and contributes to sustainable development.

Uses of Custom Galvanized Steel Grating

Custom galvanized steel grating is widely used in various industries due to its unique properties and versatility. Some common applications include

1. Industrial flooring In factories, warehouses, and distribution centers, custom galvanized steel grating is used as industrial flooring to support heavy machinery and equipment.

2. Platform and mezzanine It is often used to construct platforms and mezzanines in manufacturing facilities, warehouses, and retail stores to maximize floor space and improve efficiency.

3. Walkways and ramps Custom galvanized steel grating is ideal for creating safe and slip-resistant walkways and ramps in outdoor and indoor environments, such as parking garages, loading docks, and construction sites.

4. Trench covers It can be used as trench covers to protect workers and equipment from falling into open trenches.

5. Decorative applications Custom galvanized steel grating can also be used for decorative purposes, such as in landscaping and architectural designs.

In conclusion, custom galvanized steel grating is a versatile and durable material that offers numerous benefits for various applications. Its corrosion resistance, high strength, slip resistance, easy maintenance, and customization options make it an excellent choice for both commercial and industrial projects.

custom galvanized steel grating. It is commonly used in industrial floors, platforms, walkways, and ramps.

3. Cost-effective Although custom galvanized steel grating may have a higher initial cost compared to other materials, its durability and long service life can help reduce maintenance and replacement costs over time.

4. Environmental friendliness Zinc is a non-toxic and recyclable material, making custom galvanized steel grating environmentally friendly. It has a low carbon footprint and contributes to sustainable development.

Uses of Custom Galvanized Steel Grating

Custom galvanized steel grating is widely used in various industries due to its unique properties and versatility. Some common applications include

1. Industrial flooring In factories, warehouses, and distribution centers, custom galvanized steel grating is used as industrial flooring to support heavy machinery and equipment.

2. Platform and mezzanine It is often used to construct platforms and mezzanines in manufacturing facilities, warehouses, and retail stores to maximize floor space and improve efficiency.

3. Walkways and ramps Custom galvanized steel grating is ideal for creating safe and slip-resistant walkways and ramps in outdoor and indoor environments, such as parking garages, loading docks, and construction sites.

4. Trench covers It can be used as trench covers to protect workers and equipment from falling into open trenches.

5. Decorative applications Custom galvanized steel grating can also be used for decorative purposes, such as in landscaping and architectural designs.

In conclusion, custom galvanized steel grating is a versatile and durable material that offers numerous benefits for various applications. Its corrosion resistance, high strength, slip resistance, easy maintenance, and customization options make it an excellent choice for both commercial and industrial projects.

Safety The slip-resistant surface and high load capacity of custom galvanized steel grating provide a safe working environment Safety The slip-resistant surface and high load capacity of custom galvanized steel grating provide a safe working environment

Safety The slip-resistant surface and high load capacity of custom galvanized steel grating provide a safe working environment Safety The slip-resistant surface and high load capacity of custom galvanized steel grating provide a safe working environment custom galvanized steel grating. It is commonly used in industrial floors, platforms, walkways, and ramps.

3. Cost-effective Although custom galvanized steel grating may have a higher initial cost compared to other materials, its durability and long service life can help reduce maintenance and replacement costs over time.

4. Environmental friendliness Zinc is a non-toxic and recyclable material, making custom galvanized steel grating environmentally friendly. It has a low carbon footprint and contributes to sustainable development.

Uses of Custom Galvanized Steel Grating

Custom galvanized steel grating is widely used in various industries due to its unique properties and versatility. Some common applications include

1. Industrial flooring In factories, warehouses, and distribution centers, custom galvanized steel grating is used as industrial flooring to support heavy machinery and equipment.

2. Platform and mezzanine It is often used to construct platforms and mezzanines in manufacturing facilities, warehouses, and retail stores to maximize floor space and improve efficiency.

3. Walkways and ramps Custom galvanized steel grating is ideal for creating safe and slip-resistant walkways and ramps in outdoor and indoor environments, such as parking garages, loading docks, and construction sites.

4. Trench covers It can be used as trench covers to protect workers and equipment from falling into open trenches.

5. Decorative applications Custom galvanized steel grating can also be used for decorative purposes, such as in landscaping and architectural designs.

In conclusion, custom galvanized steel grating is a versatile and durable material that offers numerous benefits for various applications. Its corrosion resistance, high strength, slip resistance, easy maintenance, and customization options make it an excellent choice for both commercial and industrial projects.

custom galvanized steel grating. It is commonly used in industrial floors, platforms, walkways, and ramps.

3. Cost-effective Although custom galvanized steel grating may have a higher initial cost compared to other materials, its durability and long service life can help reduce maintenance and replacement costs over time.

4. Environmental friendliness Zinc is a non-toxic and recyclable material, making custom galvanized steel grating environmentally friendly. It has a low carbon footprint and contributes to sustainable development.

Uses of Custom Galvanized Steel Grating

Custom galvanized steel grating is widely used in various industries due to its unique properties and versatility. Some common applications include

1. Industrial flooring In factories, warehouses, and distribution centers, custom galvanized steel grating is used as industrial flooring to support heavy machinery and equipment.

2. Platform and mezzanine It is often used to construct platforms and mezzanines in manufacturing facilities, warehouses, and retail stores to maximize floor space and improve efficiency.

3. Walkways and ramps Custom galvanized steel grating is ideal for creating safe and slip-resistant walkways and ramps in outdoor and indoor environments, such as parking garages, loading docks, and construction sites.

4. Trench covers It can be used as trench covers to protect workers and equipment from falling into open trenches.

5. Decorative applications Custom galvanized steel grating can also be used for decorative purposes, such as in landscaping and architectural designs.

In conclusion, custom galvanized steel grating is a versatile and durable material that offers numerous benefits for various applications. Its corrosion resistance, high strength, slip resistance, easy maintenance, and customization options make it an excellent choice for both commercial and industrial projects. Latest news

-

Smart AI Fence Solutions with GPT-4 Turbo | Secure & Fast

NewsAug.02,2025

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025