-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Oct . 02, 2024 18:36 Back to list

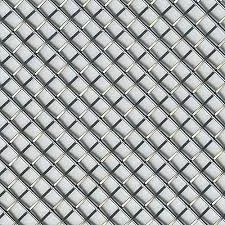

Custom Galvanized Welded Wire Mesh Solutions for Various Applications and Industries

Custom Galvanised Welded Mesh Versatility and Applications

Custom galvanised welded mesh has become an essential material in various industries due to its durability, flexibility, and resistance to corrosion. This type of mesh is produced by welding together wires that are coated with a layer of zinc, enhancing its longevity and making it ideal for a wide range of applications. Whether it's for industrial use, agricultural purposes, or even decorative installations, custom galvanised welded mesh offers solutions tailored to meet specific needs.

One of the primary advantages of galvanised welded mesh is its resistance to rust and other forms of corrosion. The galvanisation process involves immersing the steel wire in molten zinc, which creates a protective barrier. This feature is especially beneficial in environments exposed to moisture, such as agricultural fields, water treatment plants, and outdoor fencing. By utilizing custom galvanised welded mesh, businesses can reduce maintenance costs and extend the lifespan of their structures.

The versatility of custom galvanised welded mesh is evident in its various applications. In agriculture, it is commonly used for fencing livestock, creating enclosures, and supporting plant growth in greenhouses. Farmers often prefer welded mesh over traditional fencing options due to its strength and stability, which effectively keeps animals contained and deters predators. Additionally, its open design allows for adequate airflow and sunlight penetration, promoting healthy plant growth.

custom galvanised welded mesh

In the construction industry, custom galvanised welded mesh is frequently used as reinforcement for concrete. It provides structural support in applications such as slabs, walls, and foundations. The welded mesh improves the tensile strength of concrete, minimizing the risk of cracks and structural failure. This is particularly important in areas with fluctuating temperatures or seismic activities, where increased support is necessary.

Beyond practical uses, custom galvanised welded mesh also finds its place in architectural and decorative applications. Designers and architects utilize this material to create visually appealing structures, such as screens, balustrades, and façade cladding. The mesh can be customized in various wire diameters and spacing, allowing for unique designs that enhance both aesthetics and functionality. It is a popular choice for modern interior design, where transparency and light are crucial elements.

Another noteworthy application of custom galvanised welded mesh is in the manufacturing of security products. The mesh is often used in the creation of burglar-proof screens, gates, and fences. Its robust construction acts as a deterrent against intruders while ensuring visibility and ventilation. Businesses and homeowners alike have opted for custom solutions, allowing for tailored security systems that cater to specific vulnerabilities of their properties.

In conclusion, custom galvanised welded mesh stands out as a highly adaptable product that serves multiple purposes across various sectors. Its impressive resistance to corrosion, along with its structural integrity and aesthetic versatility, make it a preferred choice among builders, farmers, and designers. As industries continue to evolve, the demand for custom galvanised welded mesh is likely to grow, driven by the need for durable and cost-effective solutions. Whether for functional or decorative purposes, this versatile material proves itself indispensable in today’s market.

-

High-Quality Chicken Wire Panels Leading Manufacturer & Exporter

NewsJul.08,2025

-

High-Quality Concrete Reinforcement Wire Mesh – Reliable Steel Mesh Manufacturers & Exporters

NewsJul.08,2025

-

High-Quality Aluminum Expanded Mesh Leading Manufacturers & Exporters

NewsJul.08,2025

-

High-Quality Perforated Stainless Steel Sheet Manufacturer & Exporter Custom Sizes Available

NewsJul.07,2025

-

High-Quality Galvanized Angle Steel - Reliable Manufacturer, Exporter & Suppliers

NewsJul.07,2025

-

Premium Spiral Tomato Plant Support Stake Leading Manufacturer, Exporter & Supplier

NewsJul.06,2025