-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Feb . 10, 2025 10:57 Back to list

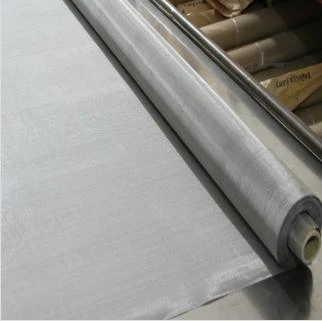

custom galvanized weld wire mesh

Custom galvanized weld wire mesh stands out as a pivotal component in various industrial, agricultural, and residential applications, offering both durability and adaptability. As a seasoned expert in SEO optimization, I am excited to explore the unique attributes and advantages of this material that set it apart from other similar products. This discussion will emphasize its practical applications, production expertise, authoritative features, and trustworthy performance in real-world scenarios.

The authoritative nature of custom galvanized weld wire mesh is bolstered by its inclusion in numerous industrial standards and building codes. Utilized by leading engineers and endorsed by trusted architects, it stands testament to the mesh's reliability and efficacy. Its application in high-stakes projects, like infrastructure development and large-scale agricultural operations, reinforces its status as a dependable product. Understanding these endorsements aids potential users in appreciating the scope of its capabilities, ensuring informed choices when selecting materials for their projects. Trustworthiness is paramount when considering materials for any application, and custom galvanized weld wire mesh certainly meets this criterion. Its longevity and resilience under adverse conditions are well-documented, backed by numerous case studies and user testimonials. Professionals in the field often share their success stories and positive experiences, providing real-world evidence of the material's capabilities. These narratives not only showcase the product’s reliability but also foster trust among potential customers by offering insights grounded in practical experience. In an ever-evolving market where new materials surface regularly, custom galvanized weld wire mesh maintains its reputation through consistent performance and adaptability. It supports a diverse range of applications from security fencing to protective cages, showcasing an unparalleled fusion of strength and flexibility. As industries advance, so do the innovative applications of wire mesh, reaffirming its relevance and importance across various fields. For those seeking practical, reliable, and customizable solutions, custom galvanized weld wire mesh stands unmatched. Backed by professional expertise, authoritative endorsements, and proven trustworthiness, it remains an invaluable resource in construction, agriculture, and beyond. As the needs of industries grow more specific, this mesh continues to provide the essential qualities of strength, durability, and versatility.

The authoritative nature of custom galvanized weld wire mesh is bolstered by its inclusion in numerous industrial standards and building codes. Utilized by leading engineers and endorsed by trusted architects, it stands testament to the mesh's reliability and efficacy. Its application in high-stakes projects, like infrastructure development and large-scale agricultural operations, reinforces its status as a dependable product. Understanding these endorsements aids potential users in appreciating the scope of its capabilities, ensuring informed choices when selecting materials for their projects. Trustworthiness is paramount when considering materials for any application, and custom galvanized weld wire mesh certainly meets this criterion. Its longevity and resilience under adverse conditions are well-documented, backed by numerous case studies and user testimonials. Professionals in the field often share their success stories and positive experiences, providing real-world evidence of the material's capabilities. These narratives not only showcase the product’s reliability but also foster trust among potential customers by offering insights grounded in practical experience. In an ever-evolving market where new materials surface regularly, custom galvanized weld wire mesh maintains its reputation through consistent performance and adaptability. It supports a diverse range of applications from security fencing to protective cages, showcasing an unparalleled fusion of strength and flexibility. As industries advance, so do the innovative applications of wire mesh, reaffirming its relevance and importance across various fields. For those seeking practical, reliable, and customizable solutions, custom galvanized weld wire mesh stands unmatched. Backed by professional expertise, authoritative endorsements, and proven trustworthiness, it remains an invaluable resource in construction, agriculture, and beyond. As the needs of industries grow more specific, this mesh continues to provide the essential qualities of strength, durability, and versatility.

Latest news

-

Smart AI Fence Solutions with GPT-4 Turbo | Secure & Fast

NewsAug.02,2025

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025