-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Feb . 15, 2025 11:20 Back to list

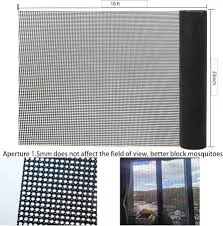

custom galvanized wire mesh

Custom galvanized wire mesh, a crucial component in the industrial and architectural sectors, offers unparalleled versatility and durability. Its application ranges from constructing sturdy fences and cages to providing an effective solution for dust and insect control. This versatile material combines strength with flexibility, making it ideal for a wide array of projects.

One of the standout features of custom galvanized wire mesh is its role in environmental sustainability. Its longevity means fewer resources are used over time, and at the end of its life, galvanized wire mesh can be recycled, reducing its environmental footprint. Its durability and recyclability align well with the increasing shift towards more sustainable building practices and products. Ensuring quality in custom galvanized wire mesh goes beyond the manufacturing process; it involves rigorous testing and quality assurance measures. Verified producers often conduct salt spray tests and other assessments to confirm the mesh’s resistance to corrosion, ensuring it meets industry standards. Choosing a supplier committed to quality assurance is crucial for buyers wanting to invest in a product known for its long-term performance and reliability. Trust is pivotal in the selection of a galvanized wire mesh supplier. Reliable suppliers provide comprehensive documentation and certification regarding the coating weight and material composition, reinforcing transparency and providing reassurance of product quality. Engaging with suppliers who offer warranties and customer support further enhances trust, providing a safety net for investments in the mesh. In terms of SEO strategy, integrating user reviews and case studies on how custom galvanized wire mesh has performed in various scenarios can vastly improve a website's E-E-A-T (Experience-Expertise-Authoritativeness-Trustworthiness). Encouraging feedback from constructors who have utilized the mesh in challenging conditions or entrepreneurs who have innovatively applied it in niche markets adds layers of credibility and user-generated content. In conclusion, custom galvanized wire mesh stands out not only for its robustness and flexibility but also for its adaptability to diverse applications. It embodies a blend of strength, longevity, and sustainability, making it an indomitable choice for industry professionals. Understanding and leveraging this product's unique properties can effectively enhance project outcomes and push the boundaries of innovative design and construction.

One of the standout features of custom galvanized wire mesh is its role in environmental sustainability. Its longevity means fewer resources are used over time, and at the end of its life, galvanized wire mesh can be recycled, reducing its environmental footprint. Its durability and recyclability align well with the increasing shift towards more sustainable building practices and products. Ensuring quality in custom galvanized wire mesh goes beyond the manufacturing process; it involves rigorous testing and quality assurance measures. Verified producers often conduct salt spray tests and other assessments to confirm the mesh’s resistance to corrosion, ensuring it meets industry standards. Choosing a supplier committed to quality assurance is crucial for buyers wanting to invest in a product known for its long-term performance and reliability. Trust is pivotal in the selection of a galvanized wire mesh supplier. Reliable suppliers provide comprehensive documentation and certification regarding the coating weight and material composition, reinforcing transparency and providing reassurance of product quality. Engaging with suppliers who offer warranties and customer support further enhances trust, providing a safety net for investments in the mesh. In terms of SEO strategy, integrating user reviews and case studies on how custom galvanized wire mesh has performed in various scenarios can vastly improve a website's E-E-A-T (Experience-Expertise-Authoritativeness-Trustworthiness). Encouraging feedback from constructors who have utilized the mesh in challenging conditions or entrepreneurs who have innovatively applied it in niche markets adds layers of credibility and user-generated content. In conclusion, custom galvanized wire mesh stands out not only for its robustness and flexibility but also for its adaptability to diverse applications. It embodies a blend of strength, longevity, and sustainability, making it an indomitable choice for industry professionals. Understanding and leveraging this product's unique properties can effectively enhance project outcomes and push the boundaries of innovative design and construction.

Latest news

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025