-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Oct . 05, 2024 09:30 Back to list

Custom Coated Hot Dipped Galvanized Wire for Versatile Applications and Enhanced Durability

Custom Hot Dipped Galvanized Wire An Essential Material for Various Applications

Hot dipped galvanized wire has become increasingly popular in various industries due to its durability and resistance to corrosion. This type of wire is coated with a layer of zinc through the process of hot dipping, which involves immersing the wire in molten zinc. The result is a robust and long-lasting material that is ideal for a wide range of applications.

One of the most significant advantages of hot dipped galvanized wire is its exceptional resistance to rust and corrosion. This property makes it particularly valuable for outdoor applications, where exposure to the elements can lead to rapid deterioration of uncoated metal products. By offering a protective barrier, hot dipped galvanized wire ensures longevity and reliability, making it a preferred choice in construction, fencing, agriculture, and more.

In the construction industry, custom hot dipped galvanized wire is often used for reinforcement purposes. It provides structural integrity to concrete and masonry, ensuring that buildings and other structures can withstand various stresses. The wire is commonly used in concrete reinforcement, welded wire fabric, and other construction applications that require high strength and durability. Builders appreciate how this type of wire can significantly extend the lifecycle of their projects, reducing maintenance costs over time.

Fencing is another significant application for hot dipped galvanized wire. Whether for residential, agricultural, or industrial purposes, fences made from this type of wire offer superior strength and resistance to environmental challenges. They can withstand harsh weather conditions, including rain, snow, and extreme temperatures, making them an ideal choice for securing properties and livestock. Custom hot dipped galvanized wire can be tailored to meet specific fencing needs, such as different gauges, lengths, and coatings, providing flexibility to accommodate various projects.

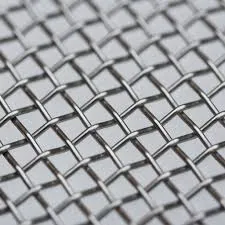

custom hot dipped galvanized wire

The agriculture sector also benefits from the use of hot dipped galvanized wire. Farmers utilize this wire for various applications, including animal husbandry, trellising for crops, and fencing to protect livestock from predators. The long-lasting nature of galvanized wire reduces the frequency of replacement, allowing farmers to focus on their operations rather than continuous repairs. Additionally, the wire provides safe and secure environments for animals, contributing to better agricultural practices.

In addition to its applications in construction, fencing, and agriculture, custom hot dipped galvanized wire is used in manufacturing and crafting. It serves as a critical component in the production of wire mesh, hooks, and other industrial products that require strength and resilience. Its versatility allows it to be molded into various shapes and sizes, making it suitable for custom applications.

When seeking custom hot dipped galvanized wire, it is essential to collaborate with reputable manufacturers who understand the specific requirements of your project. They can provide guidance on the right specifications, including wire thickness, coating weight, and processing methods to meet your needs efficiently.

In conclusion, custom hot dipped galvanized wire is an invaluable material across various industries, including construction, agriculture, and manufacturing. Its exceptional resistance to corrosion, coupled with the ability to customize specifications, makes it a go-to choice for those seeking durability and reliability. As industries continue to evolve, the demand for high-quality hot dipped galvanized wire will undoubtedly remain strong, ensuring its place as a staple material in numerous applications.

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025