-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Nov . 12, 2024 08:59 Back to list

custom low carbon steel wire

Custom Low Carbon Steel Wire A Sustainable Solution for Various Applications

In recent years, the demand for low-carbon materials has surged, reflecting a growing awareness of sustainability and environmental conservation. Among these materials, custom low carbon steel wire has emerged as a versatile solution that caters to a wide range of industries, from construction to manufacturing. This article explores the benefits, applications, and production processes of custom low carbon steel wire, highlighting its significant contributions to a greener future.

Understanding Low Carbon Steel

Low carbon steel, often referred to as mild steel, typically contains less than 0.3% carbon by weight. This composition endows it with remarkable properties such as high ductility, malleability, and weldability, making it highly adaptable for various applications. The lower carbon content also means that low carbon steel is less brittle than its high-carbon counterparts, allowing it to absorb impact without easily breaking.

Benefits of Custom Low Carbon Steel Wire

1. Strength and Durability Despite its low carbon content, low carbon steel wire offers substantial tensile strength, making it reliable for structural applications. Its ability to withstand stress and deformation under various loading conditions is crucial in construction and engineering projects.

2. Cost-Effectiveness Custom low carbon steel wire is relatively inexpensive compared to other materials like stainless steel or high-carbon wire. This affordability makes it an attractive choice for manufacturers looking to minimize costs while maintaining quality.

3. Versatility One of the most significant advantages of custom low carbon steel wire is its adaptability. It can be tailored to meet specific requirements, including diameter, tensile strength, and coating, ensuring compatibility with diverse applications ranging from automotive parts to agriculture.

4. Environmental Benefits The production of low carbon steel requires less energy compared to higher carbon steels, contributing to lower carbon emissions. Additionally, methods to recycle low carbon steel are well established, further enhancing its sustainability profile.

Applications of Custom Low Carbon Steel Wire

Custom low carbon steel wire finds applications across various sectors

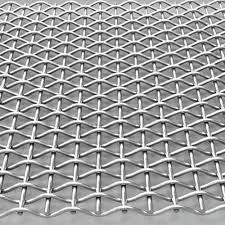

- Construction In the construction industry, this wire is used for reinforcing concrete, creating wire mesh, and manufacturing pre-fabricated components. Its strong yet flexible nature is crucial for ensuring the integrity of structures.

custom low carbon steel wire

- Manufacturing In manufacturing settings, custom low carbon steel wire is utilized in the production of automotive parts, machinery, and tools. Its malleability allows for intricate designs and shapes, making it ideal for complex components.

- Agriculture Agricultural industries rely on low carbon steel wire for fencing, trellises, and various support structures. Its resistance to corrosion (when coated) ensures longevity in outdoor environments.

- Crafts and DIY Projects The wire is also popular among artisans and hobbyists for crafting, jewelry making, and home improvement projects. Its ease of manipulation allows for a wide array of creative applications.

Production Process

The production of custom low carbon steel wire involves several steps

1. Melting and Refining Raw materials (scrap steel, pig iron, etc.) are melted in a furnace and refined to achieve the desired carbon content and purity.

2. Wire Drawing The molten steel is formed into coils and drawn through a series of dies to achieve the desired diameter. This process enhances the wire's strength and flexibility.

3. Heat Treatment Depending on the desired properties, the wire may undergo heat treatment processes such as annealing to relieve internal stresses and improve ductility.

4. Coating To enhance corrosion resistance, a coating (such as galvanization) may be applied. This step is crucial for applications exposed to harsh environmental conditions.

Conclusion

Custom low carbon steel wire represents a sustainable and versatile material that meets the demands of modern industries. Its balance of strength, cost-effectiveness, and adaptability makes it an invaluable resource across multiple applications. As industries continue to prioritize sustainability and efficiency, the role of custom low carbon steel wire in contributing to a greener future cannot be overstated. With ongoing advancements in production techniques and a commitment to recycling, it is poised to remain a staple in the material science landscape for years to come.

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025