-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Oct . 19, 2024 11:38 Back to list

Cost of Custom Perforated Metal Sheets for Various Applications

Understanding the Pricing of Custom Perforated Metal Sheets

Perforated metal sheets are an essential component in various industries, serving multiple purposes ranging from architectural applications to functional industrial uses. As businesses look to incorporate these versatile materials into their projects, understanding the pricing associated with custom perforated metal sheets becomes increasingly important. Several factors influence the cost, and knowing these can assist in making informed purchasing decisions.

What is Custom Perforated Metal?

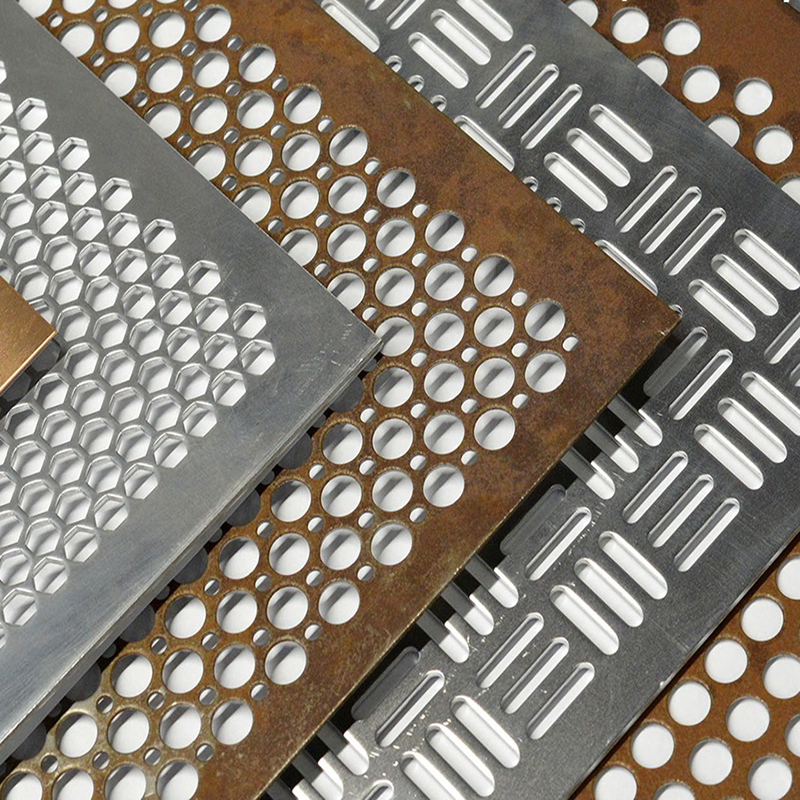

Custom perforated metal sheets are metal panels that have been engineered with a pattern of holes, either for aesthetic, functional, or both reasons. They can be made from a variety of metals, including aluminum, stainless steel, brass, and more. The perforations can come in different shapes, sizes, and patterns, allowing for a high degree of customization. Common uses include

1. Architectural Design Used in facades, screens, and railings for visual appeal and ventilation. 2. Industrial Applications Used as filters, trays, and guards to improve functionality. 3. Acoustic Control Enhancing sound absorption in spaces like auditoriums and studios. 4. Safety and Security Providing structure while allowing visibility and airflow.

Price Influencers

Several key factors influence the pricing of custom perforated metal sheets

1. Material Type The type of metal selected dramatically affects the cost. For example, stainless steel is generally more expensive than aluminum but offers superior durability and corrosion resistance. The choice between materials should reflect the intended application and budget constraints.

2. Sheet Thickness Thicker sheets are more expensive due to the increased material costs and the additional processing required for perforation. The thickness needed often corresponds with the load the sheet must support or the expected wear over time.

custom perforated metal sheet price

3. Perforation Pattern The complexity of the hole pattern plays a significant role in pricing. Simple round holes may cost less than intricate designs. Custom patterns that require specialized machining or tools may incur extra charges, reflecting the labor and machine use involved.

4. Dimensions The size of the perforated metal sheet also impacts its price. Larger sheets require more material and may lead to increased shipping costs. Additionally, custom dimensions may lead to higher manufacturing costs if standard sizes are not used.

5. Quantity The volume of the order can affect pricing significantly. Larger quantities often benefit from economies of scale, reducing the per-unit cost. Conversely, small orders may incur a premium due to setup and production costs.

6. Finishing Techniques Additional treatments such as powder coating, painting, or galvanizing to enhance the appearance and protect against corrosion can also add to the overall price. The chosen finish can impact both aesthetics and longevity, so it’s essential to consider these aspects when budgeting.

7. Lead Time Custom products could take longer to manufacture, and if a quick turnaround is needed, rush fees may be applied. It's beneficial to plan ahead and order early when possible.

Conclusion

When budgeting for custom perforated metal sheets, it is essential to consider all these variable factors. Shopping around and obtaining quotes from various suppliers can provide valuable insight into fair market prices. It's also wise to discuss specific needs and applications with manufacturers to ensure the final product meets expectations without compromising on quality.

By grasping the intricacies of pricing for custom perforated metal sheets, businesses can better navigate their options and make decisions that align with their project goals and financial constraints. Regardless of the intended use, investing wisely in perforated metal can lead to functional, durable, and visually appealing results that enhance any project.

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025