-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Nov . 16, 2024 02:29 Back to list

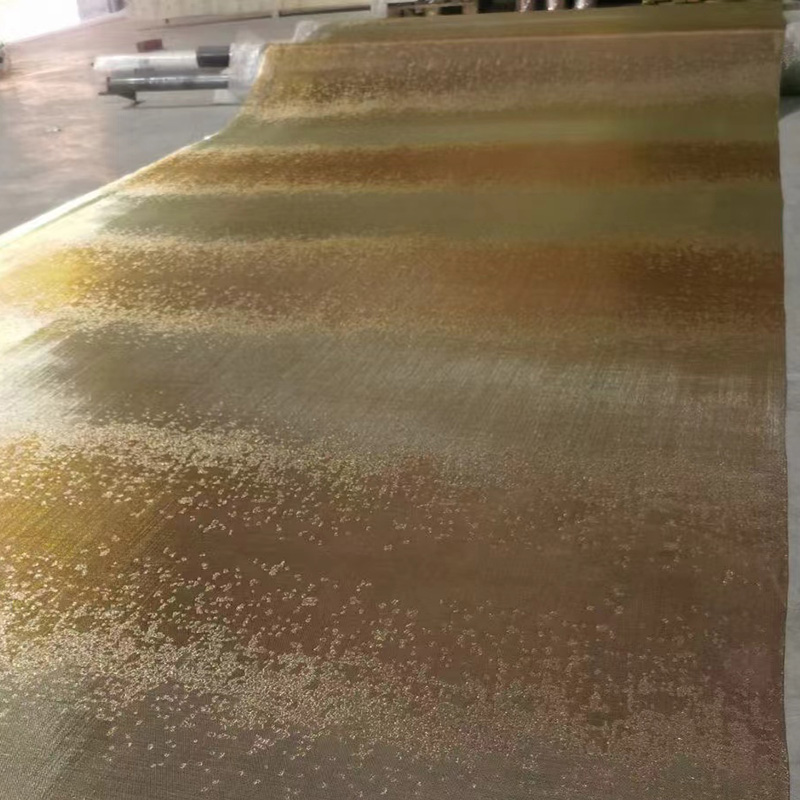

custom stainless steel crimped woven wire mesh

Custom Stainless Steel Crimped Woven Wire Mesh A Versatile Solution for Various Applications

In today’s world, the need for durable, versatile, and effective filtering solutions has become increasingly important across various industries. Among the myriad of materials available, custom stainless steel crimped woven wire mesh stands out due to its unique properties and adaptability. This specialized mesh is not only robust but also offers a multitude of benefits that cater to diverse applications such as mining, agriculture, construction, and food processing.

Understanding Crimped Woven Wire Mesh

Crimped woven wire mesh is created by weaving stainless steel wires together in a crimped formation, providing a reliable network that can withstand significant stress and strain. The crimping process involves altering the shape of the wire before it is woven, which enhances the mesh's structural integrity and resistance to external forces. This distinctive design allows for various opening sizes, making it suitable for multiple functions, from filtering to security.

Key Benefits of Custom Stainless Steel Crimped Woven Wire Mesh

1. Corrosion Resistance Situated in environments exposed to moisture, chemicals, or extreme temperatures, stainless steel exhibits excellent resistance to corrosion. This makes crimped woven wire mesh ideal for industries where durability is paramount and products must withstand harsh conditions without degrading.

2. Customizability The ability to customize the specifications of the mesh—such as wire diameter, mesh opening size, crimp pattern, and overall dimensions—makes it suitable for specific applications. Whether you require fine mesh for filtration or thicker wires for structural support, customization options ensure that the product meets precise requirements.

3. Strength and Durability The inherent strength of stainless steel combined with the crimped design gives the mesh remarkable durability. This makes it capable of handling substantial loads and pressures, allowing it to be used in applications that involve heavy impact or mechanical stress without compromising its integrity.

4. Aesthetic Appeal Beyond functionality, stainless steel crimped woven wire mesh also offers an aesthetic advantage. Its sleek, metallic finish can be appealing in architectural designs, where it is employed for decorative elements, safety screens, and partitions.

custom stainless steel crimped woven wire mesh

5. Versatility This mesh is applicable in a broad range of situations. In the mining industry, it acts as a screening medium for separating materials, while in agriculture, it is used for fencing and crop protection. In the food industry, it serves as a crucial component for sorting and processing materials, adhering to hygiene standards necessary for food safety.

Applications in Different Industries

1. Mining and Quarrying The mesh is extensively used in mining operations for sieving and grading materials. Its ability to handle abrasive and heavy materials ensures efficiency and longevity in demanding settings.

2. Construction In the construction industry, crimped woven wire mesh is often utilized in concrete reinforcement and as scaffolding. Its strength ensures stability in structural applications, providing safety and reliability.

3. Food Processing Crimped woven wire mesh is crucial in food manufacturing, acting as filters and separators. Its easy cleanability contributes to maintaining sanitary conditions, which is vital in food safety practices.

4. Agriculture and Gardening Farmers and gardeners frequently use this mesh for fencing, trellising, and pest protection. Its strength ensures durability against both weather elements and potential damage from animals.

Conclusion

Custom stainless steel crimped woven wire mesh is a highly versatile product that addresses the needs of various industries with its unique combination of strength, durability, and aesthetic appeal. Whether for practical use in filtration, structural applications, or aesthetic purposes, its customizability ensures that it can meet specific project requirements. As industries continue to seek sustainable and robust solutions, crimped woven wire mesh remains a go-to choice for professionals looking to enhance efficiency and performance in their operations.

-

Smart AI Fence Solutions with GPT-4 Turbo | Secure & Fast

NewsAug.02,2025

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025