-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Feb . 08, 2025 03:34 Back to list

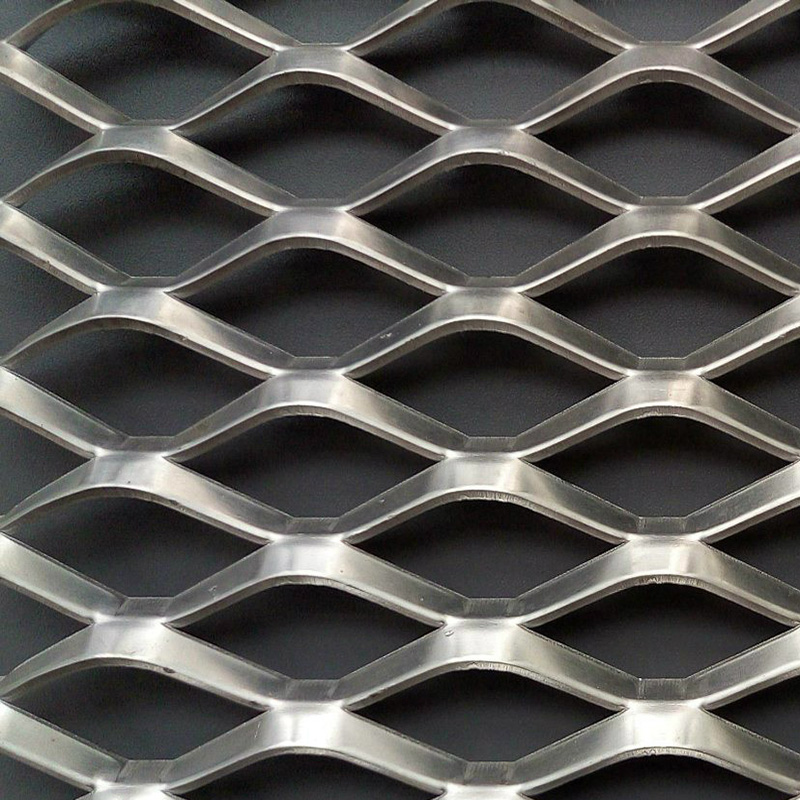

custom stainless steel woven wire mesh

Custom stainless steel woven wire mesh has become an indispensable component in a multitude of industrial and architectural applications. Its unique blend of durability, versatility, and aesthetic appeal makes it a preferred choice for engineers, architects, and designers seeking materials that meet the highest standards of quality and performance.

Authoritative voices within the industry, backed by numerous case studies and years of application, continue to recommend stainless steel woven wire mesh for its unmatched strength-to-weight ratio. This ensures that structures maintain their integrity without unnecessary heaviness. In the automotive and aerospace industries, where weight reduction is crucial, this becomes a significant advantage. This authoritative recommendation is supported by critical research and development in stainless steel technology, focusing on enhancing the intrinsic benefits of woven wire mesh. The trustworthiness of stainless steel woven wire mesh is confirmed through rigorous testing and validation processes conducted by quality assurance experts. Before reaching the market, each batch undergoes stringent tests to ensure it meets both national and international safety and quality standards. This commitment to quality assurance has built a strong reputation for stainless steel mesh, not only as a reliable product but as a material that promises longevity and consistency. In practical terms, real-world experience also emphasizes the ease of installation and maintenance associated with stainless steel woven wire mesh. For many construction projects, time is of the essence. The straightforward installation process of this mesh saves on labor costs and timelines. Maintenance is equally hassle-free, with the mesh requiring minimal upkeep to retain its appearance and functionality. This practical advantage is echoed in testimonials from project managers and construction teams who consistently highlight how seamlessly woven wire mesh fits into diverse projects. In conclusion, custom stainless steel woven wire mesh is more than just a material; it is a comprehensive solution for a host of industrial and architectural needs. Its application is backed by a robust foundation of durability, versatility, and aesthetic appeal, making it an irreplaceable choice in modern design and industry. With authoritative endorsements and proven real-world applications, it continues to build trust among professionals who demand the highest standards from their materials.

Authoritative voices within the industry, backed by numerous case studies and years of application, continue to recommend stainless steel woven wire mesh for its unmatched strength-to-weight ratio. This ensures that structures maintain their integrity without unnecessary heaviness. In the automotive and aerospace industries, where weight reduction is crucial, this becomes a significant advantage. This authoritative recommendation is supported by critical research and development in stainless steel technology, focusing on enhancing the intrinsic benefits of woven wire mesh. The trustworthiness of stainless steel woven wire mesh is confirmed through rigorous testing and validation processes conducted by quality assurance experts. Before reaching the market, each batch undergoes stringent tests to ensure it meets both national and international safety and quality standards. This commitment to quality assurance has built a strong reputation for stainless steel mesh, not only as a reliable product but as a material that promises longevity and consistency. In practical terms, real-world experience also emphasizes the ease of installation and maintenance associated with stainless steel woven wire mesh. For many construction projects, time is of the essence. The straightforward installation process of this mesh saves on labor costs and timelines. Maintenance is equally hassle-free, with the mesh requiring minimal upkeep to retain its appearance and functionality. This practical advantage is echoed in testimonials from project managers and construction teams who consistently highlight how seamlessly woven wire mesh fits into diverse projects. In conclusion, custom stainless steel woven wire mesh is more than just a material; it is a comprehensive solution for a host of industrial and architectural needs. Its application is backed by a robust foundation of durability, versatility, and aesthetic appeal, making it an irreplaceable choice in modern design and industry. With authoritative endorsements and proven real-world applications, it continues to build trust among professionals who demand the highest standards from their materials.

Latest news

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025