-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Feb . 06, 2025 01:42 Back to list

custom steel wire

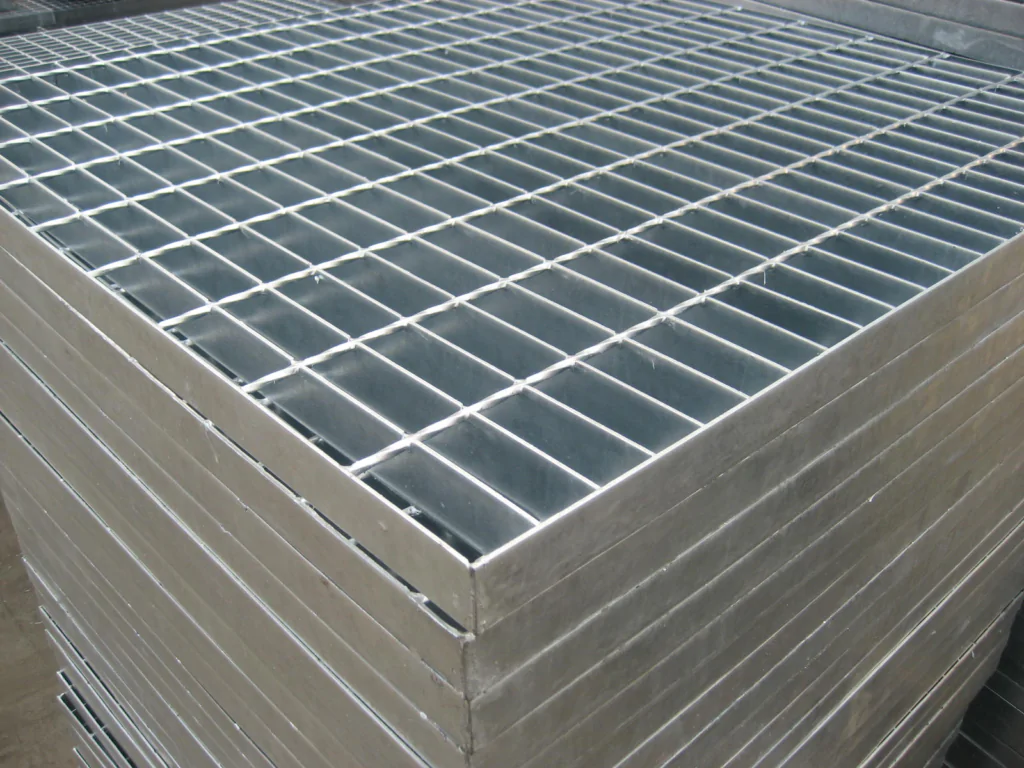

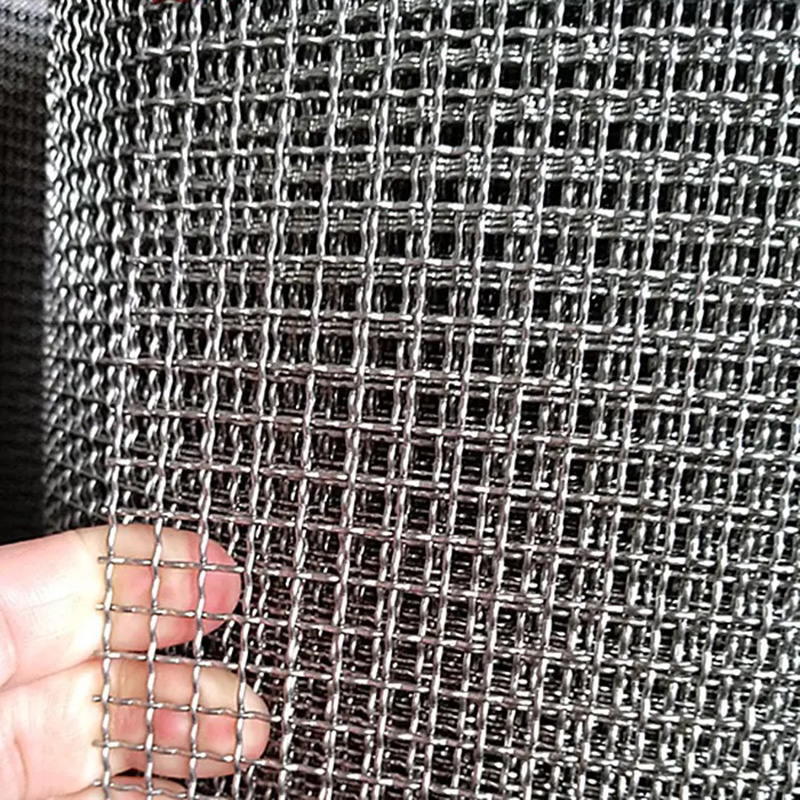

Custom steel wire is an essential material central to a diverse array of industries, offering unparalleled versatility, strength, and customization options. For companies aiming to harness these qualities, understanding the nuances of custom steel wire is crucial. Its application ranges from construction and manufacturing to bespoke artisanal projects, each demanding a tailored approach to maximize the material's potential.

The selection of a reputable supplier is fundamental to ensuring a consistent supply of high-quality custom steel wire. Leading suppliers invest in cutting-edge manufacturing technologies, such as computer-aided design (CAD) and robotics, to produce wire that meets exact specifications. Additionally, they adhere to rigorous quality control measures, ensuring each batch of custom steel wire meets or exceeds industry standards. Building a strong relationship with a trusted supplier guarantees not just quality, but also reliability and expert guidance throughout the purchasing process. Companies considering the use of custom steel wire must also evaluate the sustainability of their options. Modern suppliers increasingly offer eco-friendly wire solutions, incorporating recycled materials and energy-efficient production processes. This approach not only reduces the carbon footprint of projects but also aligns with global sustainability goals and improves brand reputation among environmentally-conscious consumers. To optimize the benefits of custom steel wire, industry stakeholders must invest time in research and development, exploring new alloy compositions and manufacturing techniques. Continuous innovation is key to maintaining a competitive edge and unlocking new applications. Engaging with industry experts and attending sector-specific expos can provide invaluable insights into emerging technologies and market trends. In conclusion, custom steel wire is more than just a material—it is a foundation for innovation and excellence across multiple industries. By leveraging its customizable properties and staying informed about technological advancements, businesses and artisans alike can secure a competitive advantage, ensuring both immediate project success and long-term growth. Through this lens, custom steel wire emerges as not only a physical link within the structures and machines that define modernity but also an emblem of human ingenuity and craftsmanship.

The selection of a reputable supplier is fundamental to ensuring a consistent supply of high-quality custom steel wire. Leading suppliers invest in cutting-edge manufacturing technologies, such as computer-aided design (CAD) and robotics, to produce wire that meets exact specifications. Additionally, they adhere to rigorous quality control measures, ensuring each batch of custom steel wire meets or exceeds industry standards. Building a strong relationship with a trusted supplier guarantees not just quality, but also reliability and expert guidance throughout the purchasing process. Companies considering the use of custom steel wire must also evaluate the sustainability of their options. Modern suppliers increasingly offer eco-friendly wire solutions, incorporating recycled materials and energy-efficient production processes. This approach not only reduces the carbon footprint of projects but also aligns with global sustainability goals and improves brand reputation among environmentally-conscious consumers. To optimize the benefits of custom steel wire, industry stakeholders must invest time in research and development, exploring new alloy compositions and manufacturing techniques. Continuous innovation is key to maintaining a competitive edge and unlocking new applications. Engaging with industry experts and attending sector-specific expos can provide invaluable insights into emerging technologies and market trends. In conclusion, custom steel wire is more than just a material—it is a foundation for innovation and excellence across multiple industries. By leveraging its customizable properties and staying informed about technological advancements, businesses and artisans alike can secure a competitive advantage, ensuring both immediate project success and long-term growth. Through this lens, custom steel wire emerges as not only a physical link within the structures and machines that define modernity but also an emblem of human ingenuity and craftsmanship.

Next:

Latest news

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

Hexagonal Gabion for Slope Protection & Retaining Walls | Durable Wire Mesh

NewsJul.29,2025