-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Nov . 21, 2024 14:10 Back to list

custom welded mesh for concrete

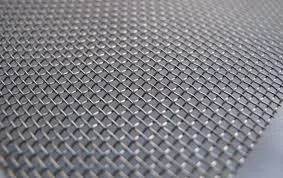

Custom Welded Mesh for Concrete Enhancing Structural Integrity and Versatility

In the world of construction and civil engineering, the materials we choose play a pivotal role in determining the durability and strength of structures. One innovative solution that has gained prominence is custom welded mesh for concrete applications. This versatile product not only enhances the structural integrity of buildings and infrastructure but also offers a range of advantages that cater to various construction needs.

Understanding Welded Mesh

Welded mesh, commonly made from high-quality steel wires, is created through a process of welding intersections at specific intervals. This creates a robust grid of interconnected wires that provides reinforcement within concrete structures. Custom welded mesh can be manufactured to fit particular project specifications, ensuring that the right gauge, spacing, and size are tailored to meet individual engineering requirements.

Enhanced Structural Integrity

One of the primary benefits of using custom welded mesh is its ability to enhance the structural integrity of concrete. Concrete, while strong in compression, is relatively weak in tension. The addition of welded mesh helps to counteract this weakness by distributing loads evenly across the structure, effectively preventing cracking and failure. This reinforcement is especially crucial in applications such as flooring, walls, and slabs, where stress concentrations can lead to significant structural challenges over time.

Customization for Specific Needs

The term custom in custom welded mesh highlights its adaptability. Each construction project presents unique challenges and requirements. By working with manufacturers to create custom specifications, engineers can ensure that the welded mesh meets the exact demands of the project. This includes considerations such as wire diameter, mesh size, and coating options. For instance, projects in corrosive environments may benefit from galvanized mesh, while others may require stainless steel for enhanced longevity.

custom welded mesh for concrete

Reduced Labor Costs and Time Efficiency

Utilizing custom welded mesh can lead to significant savings in both labor costs and project timelines. Traditional reinforcement methods, such as tying rebar together, can be labor-intensive and time-consuming. However, prefabricated welded mesh can be easily transported and installed, allowing construction teams to expedite the assembly process. As a result, projects can be completed on time and within budget, which is a critical consideration in today’s competitive construction landscape.

Sustainability Considerations

With the growing emphasis on sustainable construction practices, custom welded mesh aligns well with environmentally conscious initiatives. The durability of welded mesh means that structures reinforced with this material have a longer lifespan, reducing the need for frequent repairs or replacements. Furthermore, many manufacturers are adopting eco-friendly practices in their production processes, which can further enhance the sustainability of using welded mesh in concrete applications.

Applications Across Various Industries

Custom welded mesh is not limited to a single industry; its versatility allows for applications across a wide range of sectors, including residential, commercial, and industrial construction. Whether reinforcing foundations, creating precast concrete panels, or providing support for roadways and bridges, welded mesh serves as a reliable solution that meets the diverse needs of modern construction projects.

Conclusion

In summary, custom welded mesh for concrete is a valuable material that significantly contributes to the safety, efficiency, and sustainability of construction projects. Its strength and adaptability make it an essential choice for engineers and contractors looking to enhance the resilience of structures. As the construction industry continues to evolve, the importance of such innovative solutions will undeniably grow, paving the way for stronger and more durable infrastructures worldwide. Embracing custom welded mesh not only meets the demands of today’s construction challenges but also sets the foundation for the future of building and infrastructure development.

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025