-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Feb . 08, 2025 06:30 Back to list

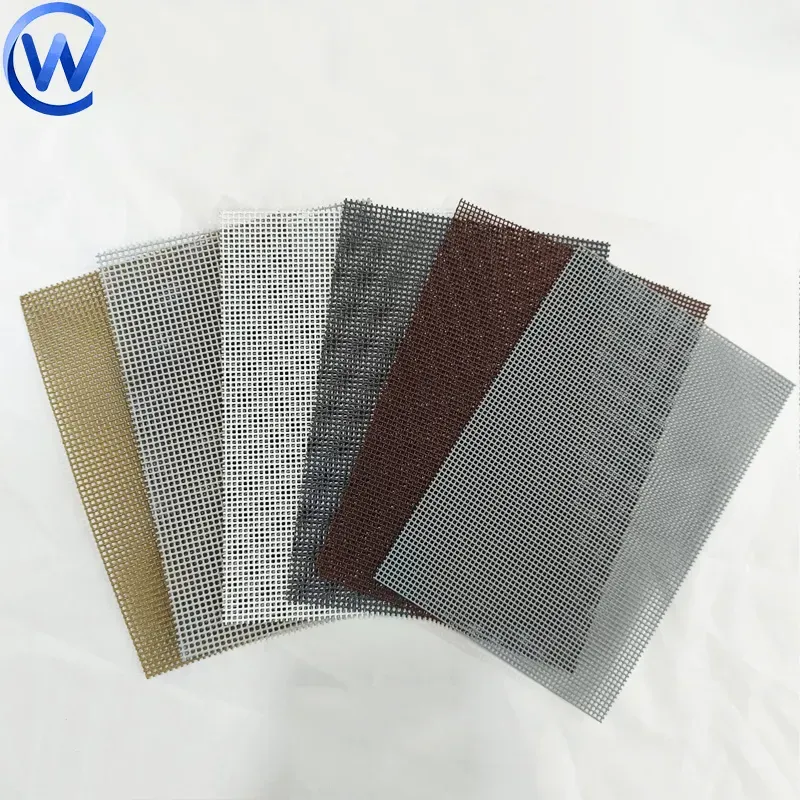

Perforated Metal Mesh

Custom wire mesh sheets have become an integral component in various industries, revolutionizing the way businesses approach both structural and design challenges. These bespoke solutions not only cater to specific requirements but also offer versatility, durability, and aesthetic appeal, making them indispensable in modern construction and architectural designs.

The trustworthiness of a supplier, particularly in the wire mesh industry, is measured by the consistency of their product quality and the satisfaction of their customer base. Certifications and compliance with international quality standards serve as indicators of a company's commitment to maintaining excellence. Moreover, customer reviews and feedback play a crucial role in establishing credibility. A manufacturer that consistently delivers on promises, maintains transparency throughout the purchasing process, and offers robust after-sales support solidifies their reputation as a trusted supplier. From a product perspective, custom wire mesh sheets offer numerous benefits. Their lightweight yet sturdy nature makes them ideal for applications where weight is a concern, without compromising on strength or durability. The ability to customize dimensions, material composition, and mesh patterns allow for creativity and personalized applications that meet specific needs. Furthermore, the open area of wire mesh can be adjusted to control airflow, light filtration, and visibility, lending it utility in HVAC systems, security screens, and decorative facades. In conclusion, custom wire mesh sheets hold unmatched versatility and resilience that cater to a vast array of industrial needs. Their utility extends beyond basic functions, providing innovative solutions that meet both practical and aesthetic demands. Ensuring expertise, establishing authority, and maintaining trustworthiness are critical factors for companies looking to excel in this sector. By prioritizing these attributes, businesses not only enhance their SEO strategy but also reinforce their position in the market as leaders in providing custom wire mesh solutions.

The trustworthiness of a supplier, particularly in the wire mesh industry, is measured by the consistency of their product quality and the satisfaction of their customer base. Certifications and compliance with international quality standards serve as indicators of a company's commitment to maintaining excellence. Moreover, customer reviews and feedback play a crucial role in establishing credibility. A manufacturer that consistently delivers on promises, maintains transparency throughout the purchasing process, and offers robust after-sales support solidifies their reputation as a trusted supplier. From a product perspective, custom wire mesh sheets offer numerous benefits. Their lightweight yet sturdy nature makes them ideal for applications where weight is a concern, without compromising on strength or durability. The ability to customize dimensions, material composition, and mesh patterns allow for creativity and personalized applications that meet specific needs. Furthermore, the open area of wire mesh can be adjusted to control airflow, light filtration, and visibility, lending it utility in HVAC systems, security screens, and decorative facades. In conclusion, custom wire mesh sheets hold unmatched versatility and resilience that cater to a vast array of industrial needs. Their utility extends beyond basic functions, providing innovative solutions that meet both practical and aesthetic demands. Ensuring expertise, establishing authority, and maintaining trustworthiness are critical factors for companies looking to excel in this sector. By prioritizing these attributes, businesses not only enhance their SEO strategy but also reinforce their position in the market as leaders in providing custom wire mesh solutions.

Next:

Latest news

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

Hexagonal Gabion for Slope Protection & Retaining Walls | Durable Wire Mesh

NewsJul.29,2025