-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Nov . 07, 2024 05:40 Back to list

Top Manufacturers of Diamond Mesh for Various Applications and Industries

Exploring the World of Diamond Mesh Manufacturers

In the modern industrial landscape, the versatility and durability of diamond mesh products have made them essential in various applications, from construction and agriculture to safety and security. As a result, the demand for high-quality diamond mesh has surged, leading to a proliferation of manufacturers in this niche market. In this article, we will explore the significance of diamond mesh products, the qualities of reputable manufacturers, and the factors to consider when selecting a supplier.

Understanding Diamond Mesh

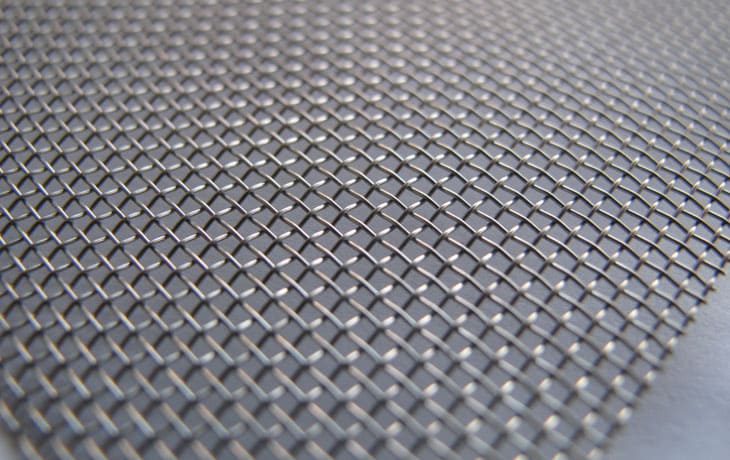

Diamond mesh, also known as diamond wire mesh, is characterized by its distinct diamond-shaped openings, which provide structural integrity and flexibility. Typically made from wire materials such as stainless steel, galvanized steel, or aluminum, diamond mesh is renowned for its durability, resistance to corrosion, and ability to withstand varying environmental conditions.

These features make diamond mesh suitable for a wide range of applications, including

1. Fencing and Enclosures Diamond mesh fencing is commonly used in residential, commercial, and agricultural settings to secure properties, enclose livestock, or protect gardens from wildlife.

2. Safety and Security The strong structure of diamond mesh makes it an ideal choice for creating barriers in construction sites, public events, and hazardous areas.

3. Architectural Designs Architects and designers use diamond mesh in decorative applications, providing a blend of functionality and aesthetic appeal in building facades and interior spaces.

4. Industrial Applications Industries often utilize diamond mesh for platform safety, equipment protection, and even as a component in manufacturing processes.

Qualities of Reputable Diamond Mesh Manufacturers

When considering diamond mesh manufacturers, several key qualities should be evaluated to ensure the procurement of high-quality products

1. Experience and Expertise Reputable manufacturers bring years of experience and industry expertise to the table. An established company is likely to have refined production processes, better quality control measures, and a deep understanding of customer needs.

diamond mesh manufacturers

2. Quality of Materials Premium diamond mesh products are made from high-grade materials that enhance strength and resistance to wear and tear. Manufacturers should be transparent about the materials used and provide certifications where applicable.

3. Customization Options Each project can come with unique requirements; therefore, the ability to customize dimensions, wire thickness, and mesh patterns is a significant advantage. A good manufacturer will work closely with customers to deliver tailored solutions.

4. State-of-the-Art Manufacturing Techniques Advanced manufacturing techniques, such as automated welding and precision cutting, enhance the quality and consistency of diamond mesh products. Suppliers employing the latest technology can provide more reliable and efficient production.

5. Customer Support and Service A manufacturer that prioritizes customer satisfaction will offer comprehensive support, from initial consultations to after-sales services. Feedback mechanisms and a responsive customer service team are indicators of a manufacturer that values its clients.

Factors to Consider When Selecting a Manufacturer

1. Reputation and Reviews Researching customer reviews and testimonials can offer valuable insights into a manufacturer’s reliability and product quality. Online platforms and industry forums can serve as useful resources.

2. Pricing Structure While cost is a significant factor in procurement, it is essential to balance price with quality. Obtaining quotes from multiple manufacturers can help identify a competitive but reasonable pricing structure.

3. Lead Times and Delivery Timely delivery is crucial for many projects. Engaging with manufacturers about their production schedules and delivery capabilities can prevent costly delays.

4. Sustainability Practices In today’s environmentally conscious landscape, manufacturers that prioritize sustainable practices in sourcing materials and reducing waste are becoming increasingly desirable.

5. Compliance and Certifications Ensure that the manufacturer adheres to industry standards and regulations. Certifications such as ISO can signify a commitment to quality management and product safety.

Conclusion

The role of diamond mesh manufacturers is pivotal in supplying products that meet the diverse needs of various industries. By understanding the key qualities of reputable manufacturers and the factors to consider when selecting a supplier, businesses can ensure they invest in high-quality diamond mesh products that will stand the test of time. As demand continues to grow, the importance of choosing the right manufacturer becomes increasingly critical in achieving project success.

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025