-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Nov . 24, 2024 15:15 Back to list

Top Double Twist Barb Wire Manufacturers for Quality Fencing Solutions and Agricultural Applications

Double Twist Barb Wire A Comprehensive Overview of Its Manufacturing Process

When it comes to ensuring security and boundary protection, few materials are as effective as barbed wire. Among the various types, double twist barb wire has emerged as a popular choice due to its enhanced security features and durability. In this article, we will delve into the manufacturing process of double twist barb wire, exploring its components, production techniques, and applications.

What is Double Twist Barb Wire?

Double twist barb wire consists of two strands of wire twisted together with barbs evenly spaced along the length of the wire. Each barb is crafted from sharp metal points that are designed to deter unauthorized access and provide security. The double twist in its name refers to the method used to create the wire, where two strands are twisted around each other, making it stronger and more resistant to vandalism and tampering.

The Key Components

The primary materials used in the production of double twist barb wire include high-tensile strength steel or galvanized iron. The choice of material is crucial because it affects the durability and resistance of the wire to weather and rust. High-tensile steel offers superior strength, making the fence more difficult to cut or break. Galvanization is a process that coats the wire with zinc, providing an additional layer of protection against corrosion.

Manufacturing Process

The manufacturing process of double twist barb wire involves several stages

1. Wire Drawing This is the first step, where large rolls of raw steel are drawn through a series of dies to create thinner wire strands of the desired gauge. This process requires precision, as the thickness of the wire greatly influences the strength and utility of the final product.

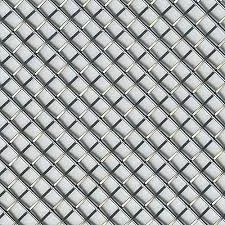

double twist barb wire manufacturer

2. Twisting The drawn wires are then twisted together. In the case of double twist barb wire, two wires are twisted in opposite directions to form a double helix. This process not only ensures greater tensile strength but also enhances flexibility.

3. Barb Formation After the twisting process, the barbs are added. This is done by cutting short lengths of wire and twisting them around the main wire at regular intervals. The placement and sharpness of these barbs are crucial for the wire’s effectiveness as a deterrent.

4. Galvanization Following the formation of the barbs, the wire is galvanized to prevent rusting and corrosion. This is typically done by immersing the wire in molten zinc, creating a robust and long-lasting protective coating.

5. Quality Control The final step in the manufacturing process involves rigorous quality control checks. This includes testing the tensile strength, inspecting the barbs for sharpness and regular spacing, and ensuring that the galvanization is uniform.

Applications

Double twist barb wire is widely used in various applications, primarily in agricultural settings, military installations, and industrial sites. Its strength and deterrent capabilities make it an excellent choice for perimeter fencing, livestock containment, and security fencing. It is also commonly found in correctional facilities and other high-security areas where safety is a primary concern.

Conclusion

The manufacturing of double twist barb wire is a specialized process that combines precision engineering with quality materials to produce a highly effective security solution. With the ever-increasing need for enhanced security measures in both public and private spaces, the demand for double twist barb wire is likely to continue growing. Its unique design and robust construction make it an essential component in the field of fencing and security. Whether it’s protecting the boundaries of a farm, securing an industrial site, or safeguarding sensitive locations, double twist barb wire plays a vital role in modern security solutions.

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025