-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Aug . 08, 2024 04:55 Back to list

Durable High-Quality Stainless Steel Woven Wire Mesh for Versatile Industrial Applications and Home Use

High-Quality Stainless Steel Woven Wire Mesh A Comprehensive Overview

In various industries and applications, the demand for durable, reliable, and highly functional materials is ever-increasing. One such material that has gained significant attention for its versatility and strength is high-quality stainless steel woven wire mesh. This specialized product is used across a multitude of sectors, including construction, food processing, pharmaceuticals, and environmental engineering, among others.

What is Stainless Steel Woven Wire Mesh?

Stainless steel woven wire mesh is a type of mesh fabric made from high-quality stainless steel wire that is interwoven to create a strong, flexible structure. The weaving process produces a product that is not only aesthetically pleasing but also functionally superior, allowing for effective filtration, separation, and protection. The inherent properties of stainless steel make this mesh resistant to corrosion, staining, and rust, thus extending its lifespan and making it suitable for various challenging environments.

Applications of Stainless Steel Woven Wire Mesh

Due to its remarkable properties, stainless steel woven wire mesh finds its applications in different fields

1. Filtration and Separation In industries such as water treatment and chemical processing, the mesh is used for filtration purposes. Its design allows for precise filtration, ensuring that only desired particulates pass through, which is crucial for maintaining the quality of outputs in these industries.

2. Architectural Design In modern architecture, stainless steel woven wire mesh is often employed in facades and interior design elements. Its strength and aesthetic appeal make it a popular choice for creating visually striking designs, while also allowing for light and air to pass through.

3. Food Processing The food industry relies heavily on stainless steel due to its hygienic properties. The mesh is used in sieving, sifting, and other processing applications, ensuring that food products meet safety and quality standards.

4. Construction and Safety In construction, stainless steel woven wire mesh is used for reinforcement in concrete structures and can serve as safety barriers in buildings. Its robustness ensures that it can withstand high stress and load conditions.

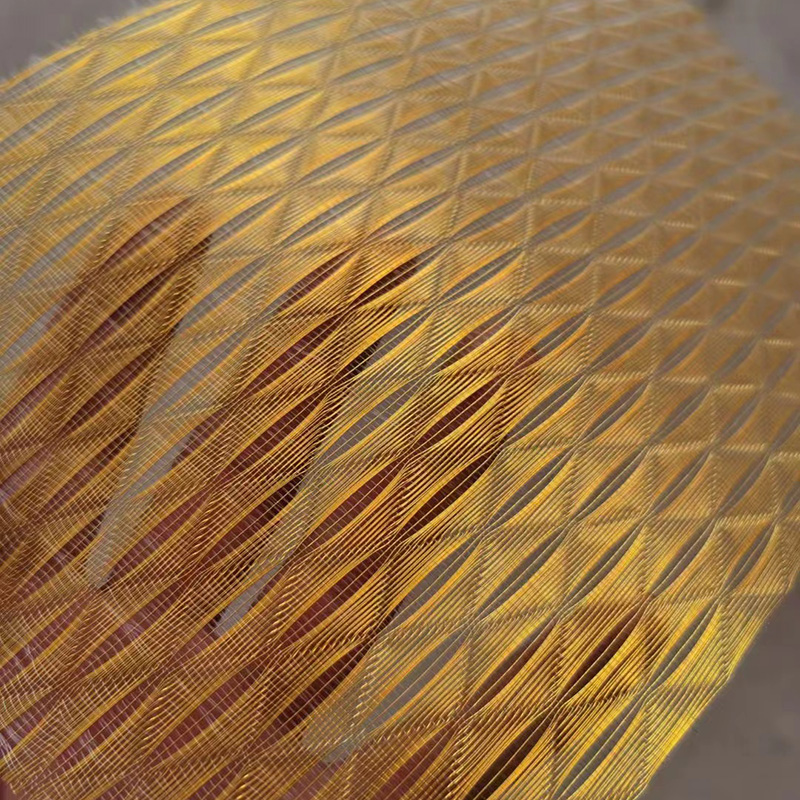

high quality stainless steel woven wire mesh

5. Medical Applications Sterile environments are essential in the medical field, and high-quality stainless steel woven wire mesh is used to create instruments, filters, and more, which must meet strict hygiene and quality standards.

Advantages of High-Quality Stainless Steel Woven Wire Mesh

1. Corrosion Resistance One of the standout features of stainless steel is its resistance to corrosion. This property makes woven wire mesh ideal for outdoor applications and in environments where it is exposed to moisture.

2. Durability High-quality stainless steel woven wire mesh possesses exceptional strength, allowing it to withstand heavy loads and stresses without breaking or deforming.

3. Versatility With a range of wire diameters, mesh openings, and weaving patterns, stainless steel woven wire mesh can be tailored to meet specific needs, enhancing its applicability across various industries.

4. Easy Maintenance The smooth surface of stainless steel makes the mesh easy to clean, which is particularly advantageous in industries like food processing and pharmaceuticals, where hygiene is paramount.

5. Aesthetic Appeal Finally, the sleek and modern look of stainless steel woven wire mesh adds a contemporary touch to architectural and design projects, making it a preferred choice for designers.

Conclusion

In conclusion, high-quality stainless steel woven wire mesh offers an array of benefits that make it indispensable in modern applications. Its strength, versatility, and resistance to environmental challenges position it as a superior choice for industries that demand high-performance materials. As technology advances and industries evolve, the role of stainless steel woven wire mesh is likely to become even more prominent in ensuring operational efficiency and enhancing product quality across the board.

-

Smart AI Fence Solutions with GPT-4 Turbo | Secure & Fast

NewsAug.02,2025

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025