-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Aug . 02, 2024 14:47 Back to list

Durable Industrial Wire Mesh Production by Leading Heavy Duty Mesh Manufacturers and Suppliers

Heavy Duty Wire Mesh Understanding the Manufacturing and Applications

In the realm of industrial materials, heavy duty wire mesh stands out as a versatile and vital product used across various sectors. As a manufacturer of heavy duty wire mesh, understanding the intricacies of production and application can help cater to diverse client needs and enhance the overall quality of the end product.

What is Heavy Duty Wire Mesh?

Heavy duty wire mesh is a type of mesh fabricated from high-strength wire strands that provide exceptional durability and resistance to heavy loads. Unlike standard wire mesh, which may be suitable for lighter applications, heavy duty wire mesh is engineered to withstand significant stress and strain. Its construction typically employs thicker wires with a tighter weave, resulting in a robust and sturdy product that can withstand harsh environments.

Manufacturing Process

The manufacturing of heavy duty wire mesh involves several steps, each crucial for ensuring quality and performance. First, high-grade raw materials, often galvanized steel or stainless steel, are selected. The use of galvanized steel helps protect against corrosion, making the mesh suitable for outdoor or humid environments.

1. Wire Drawing This initial step involves pulling the steel through a die to reduce its diameter, creating wires of specific thickness needed for the mesh.

2. Weaving The processed wire is then woven into mesh. Several methods exist for weaving, such as square weave and twill weave. The choice of weaving technique affects the mesh's overall strength and functionality.

3. Cutting and Sizing Once woven, the mesh is cut to size based on client specifications. This step may involve the use of automated machinery for precision and efficiency.

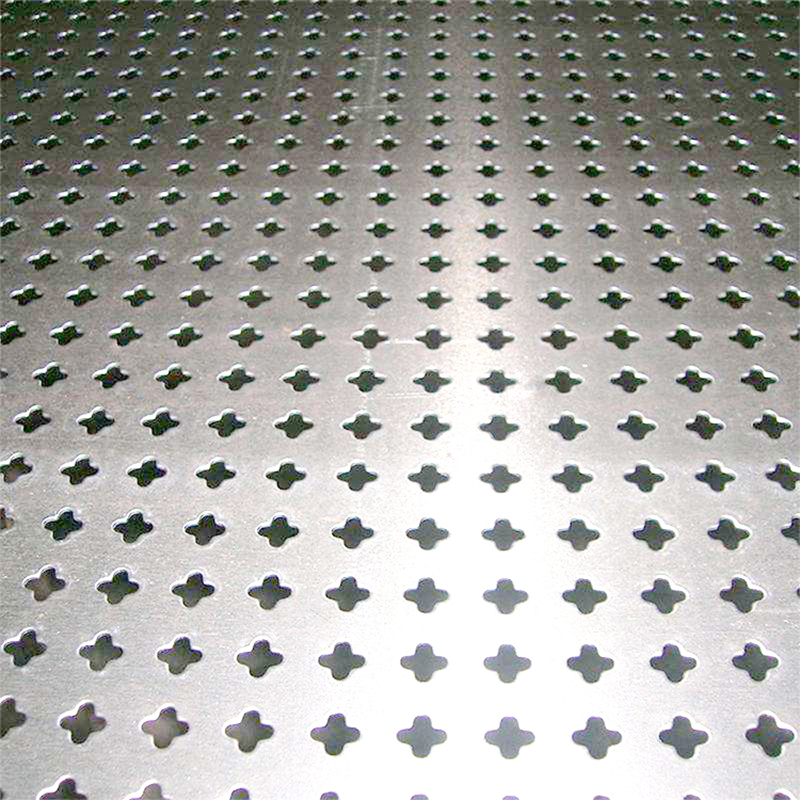

heavy duty wire mesh manufacturer

4. Finishing Treatments To enhance durability and corrosion resistance, various finishing treatments may be applied, including coating, galvanizing, or powder coating.

Applications of Heavy Duty Wire Mesh

The robust characteristics of heavy duty wire mesh make it suitable for a wide range of applications across numerous industries

- Construction In construction, heavy duty wire mesh is used for reinforcement in concrete structures, providing added strength and support. It is essential in the fabrication of concrete slabs, walls, and even pre-cast structures.

- Fencing Security fencing is another critical application. Heavy duty wire mesh is widely employed in perimeter fencing for military sites, industrial complexes, and agricultural properties due to its strength and ability to deter intruders.

- Mining and Quarrying In these industries, heavy duty wire mesh can be used for screening and sorting materials. Its strength ensures it can handle the rough treatment often encountered at mining sites.

- Transportation Heavy duty wire mesh is utilized in various conveyor systems, ensuring safe transport of materials while providing structural support.

Conclusion

As a heavy duty wire mesh manufacturer, understanding the product's manufacturing process and diverse applications is vital for meeting market demands effectively. The ability to customize mesh specifications to suit various industrial needs enhances competitiveness and contributes to customer satisfaction. With industries increasingly leaning towards durable, high-performance materials, the role of heavy duty wire mesh continues to grow, proving its worth in an array of applications, from construction to security. The future of heavy duty wire mesh seems promising, as continued innovations in manufacturing techniques and material science will likely lead to even more advanced products to meet the evolving needs of various industries.

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025