-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Dec . 11, 2024 01:07 Back to list

Electro Galvanized Wire Versatility for Construction and Industrial Applications

Understanding Electro Galvanized Wire Properties, Applications, and Benefits

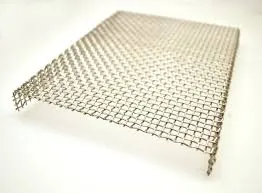

Electro galvanized wire is a type of wire that has been coated with a layer of zinc through an electroplating process. This method of galvanization serves to enhance the wire's resistance to corrosion and rust. Electro galvanized wire is utilized in a myriad of applications due to its durability and protective properties. In this article, we will explore the fundamental characteristics of electro galvanized wire, its applications across various industries, and the benefits it offers.

Properties of Electro Galvanized Wire

The primary feature that distinguishes electro galvanized wire from other types of wire is its galvanization process. Unlike hot-dip galvanization, where wire is dipped into molten zinc, electro galvanization involves an electrochemical reaction that deposits a thin layer of zinc onto the wire surface. This results in a smoother coating with a more uniform appearance.

The thickness of the zinc layer can be controlled depending on the intended use of the wire, typically ranging from 5 to 15 micrometers. This controlled coating offers good protection against corrosion for many moderate environments. However, it should be noted that electro galvanized wire is generally less durable than hot-dip galvanized wire as it provides less thickness and strength against severe weather conditions.

In addition to corrosion resistance, electro galvanized wire also exhibits good tensile strength, which makes it suitable for various applications where mechanical properties are crucial. The wire generally maintains its flexibility and can be easily bent or twisted, making it versatile for different uses.

Applications of Electro Galvanized Wire

Electro galvanized wire finds applications in numerous fields due to its beneficial properties. Here are some common uses

1. Fencing One of the most widespread applications is in fences, where electro galvanized wire can serve as a barbed wire or chain-link fence. Its corrosion resistance ensures longevity in outdoor use, making it a preferred choice for both residential and commercial fencing solutions.

2. Construction In the construction industry, electro galvanized wire is used as tying wire for rebar, enabling efficient and sturdy reinforcement of concrete structures. The wire's strength aids in efficiently securing materials during the construction process.

3. Agriculture Farmers use electro galvanized wire for various purposes, including trellising, supporting plants, and in the construction of livestock enclosures. Its resistance to rust ensures that it can withstand exposure to moisture and soil for extended periods.

electro galvanized wire

4. Home and Garden Electro galvanized wire is often used in gardening applications, such as plant supports, garden fencing, and decorative purposes. Its appealing appearance and durability make it an attractive choice for enhancing outdoor spaces.

5. Electrical Applications Due to its conductivity, electro galvanized wire can also be employed in low-voltage electrical applications, including grounding and bonding in electrical installations.

Benefits of Using Electro Galvanized Wire

Electro galvanized wire offers several advantages that make it a popular choice in various industries

1. Cost-Effective Compared to other forms of metal wire, electro galvanized wire is often more affordable, making it a practical solution for budget-conscious projects.

2. Corrosion Resistance The zinc coating provides a layer of protection against environmental factors that may lead to corrosion, extending the wire's lifespan.

3. Versatility With its wide range of applications, electro galvanized wire serves multiple functions in diverse sectors, making it highly versatile.

4. Ease of Handling The wire's ductility allows it to be easily manipulated, facilitating installation and use in a variety of situations.

5. Uniform Appearance The electroplating process gives electro galvanized wire a smooth and consistent finish, which can be aesthetically appealing in visible applications.

Conclusion

Electro galvanized wire is a valuable material that combines corrosion resistance, strength, versatility, and affordability, making it an ideal choice for various applications. From fencing and construction to agricultural and electrical uses, the wire's unique properties help ensure long-lasting performance across many settings. Understanding these aspects can aid individuals and businesses in making informed decisions when selecting materials for their projects. Whether for practical or decorative purposes, electro galvanized wire remains a reliable option in today's manufacturing and construction landscape.

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025