-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Dec . 14, 2024 11:25 Back to list

Leading Supplier of Innovative Expanded Metal Solutions for Various Industries

The Versatile World of Expanded Metal Manufacturing

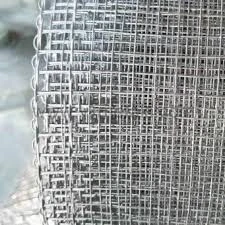

Expanded metal, a popular and versatile material, has gained immense traction in various industries due to its unique properties and wide range of applications. Expanded metal is created from a flat sheet of metal that is cut and stretched to form a network of interconnected strands, giving it an open yet sturdy structure. This manufacturing process not only enhances the strength-to-weight ratio but also allows for increased airflow, visibility, and light diffusion. In this article, we will explore the intricacies of expanded metal manufacturing, its various applications, benefits, and the factors that contribute to its enduring popularity.

The Manufacturing Process

The manufacturing of expanded metal begins with selecting the right type of metal sheet. Common materials include aluminum, steel, galvanized steel, and stainless steel. Each material offers different characteristics, such as corrosion resistance, strength, and weight, making it crucial to choose the appropriate type based on the intended use.

Once the metal sheet is chosen, it undergoes a process known as slitting, where a series of cuts are made in the sheet. This is followed by the expanding process, where the sheet is stretched, typically using automated machines that apply controlled pressure to ensure uniformity. As the metal is pulled apart, it forms a patterned mesh that can be customized in terms of aperture size and thickness, allowing manufacturers to create products that meet specific requirements.

After the expanding process, the expanded metal goes through various finishing treatments, which may include coating, painting, or galvanizing to enhance its aesthetic appeal and durability. The end product is lightweight, strong, and highly versatile, making it suitable for a wide range of applications.

Applications of Expanded Metal

Expanded metal is utilized in an array of industries, showcasing its versatility. Some of the most common applications include

1. Construction and Architecture Expanded metal is extensively used in building facades, grilles, and fencing. Its open structure allows for better airflow and natural light penetration while providing necessary structural support.

2. Safety and Security In the realm of security, expanded metal is used for guards, screens, and barriers in various settings, including industrial sites and commercial buildings. Its robust design serves as an effective deterrent against vandalism and break-ins.

3. Automotive and Aerospace The lightweight nature of expanded metal makes it an ideal choice for use in the automotive and aerospace industries. It can be found in components like heat shields, grills, and body panels, where weight reduction is crucial for performance and efficiency.

expanded metal manufacturer

4. Interior Design Designers are increasingly gravitating towards expanded metal for creative interior solutions. Its aesthetic qualities can enhance visual appeal in ceilings, partitions, and decorative features, all while maintaining functionality.

5. HVAC Systems Expanded metal is also commonly used in heating, ventilation, and air conditioning (HVAC) systems. It allows for optimal airflow while providing a sturdy structure for filters and ducts.

Benefits of Expanded Metal

The popularity of expanded metal can be attributed to several inherent benefits

- Strength and Durability The manufacturing process enhances the strength of the metal, making it resistant to bending and deformation under stress. It has a high strength-to-weight ratio, which is especially beneficial in applications where weight is a concern.

- Cost-Effectiveness Expanded metal is often more economical compared to solid metal sheets, as it uses less material while maintaining structural integrity. This makes it an attractive option for budget-conscious projects.

- Customization Manufacturers can easily customize expanded metal sheets to meet specific requirements concerning size, aperture shape, and thickness, making it a flexible solution for various applications.

- Sustainability Many expanded metal manufacturers utilize recycled materials, making it an environmentally friendly option. Additionally, the longevity and durability of expanded metal products ensure that they require minimal maintenance throughout their lifespan.

Conclusion

As the demand for versatile and cost-effective materials continues to grow, expanded metal manufacturing stands out as a crucial player across multiple industries. Its unique properties, coupled with the ability to customize, make it an exemplary choice for architects, designers, and manufacturers alike. As technology and manufacturing processes evolve, the applications for expanded metal are likely to expand, solidifying its position as a staple in modern construction and design. The future of expanded metal looks bright, promising innovative solutions that blend functionality with aesthetic appeal.

-

Smart AI Fence Solutions with GPT-4 Turbo | Secure & Fast

NewsAug.02,2025

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025