-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Jul . 29, 2024 06:39 Back to list

Exploring the Benefits and Applications of Steel Matting in Construction and Infrastructure Development

The Importance and Applications of Steel Matting

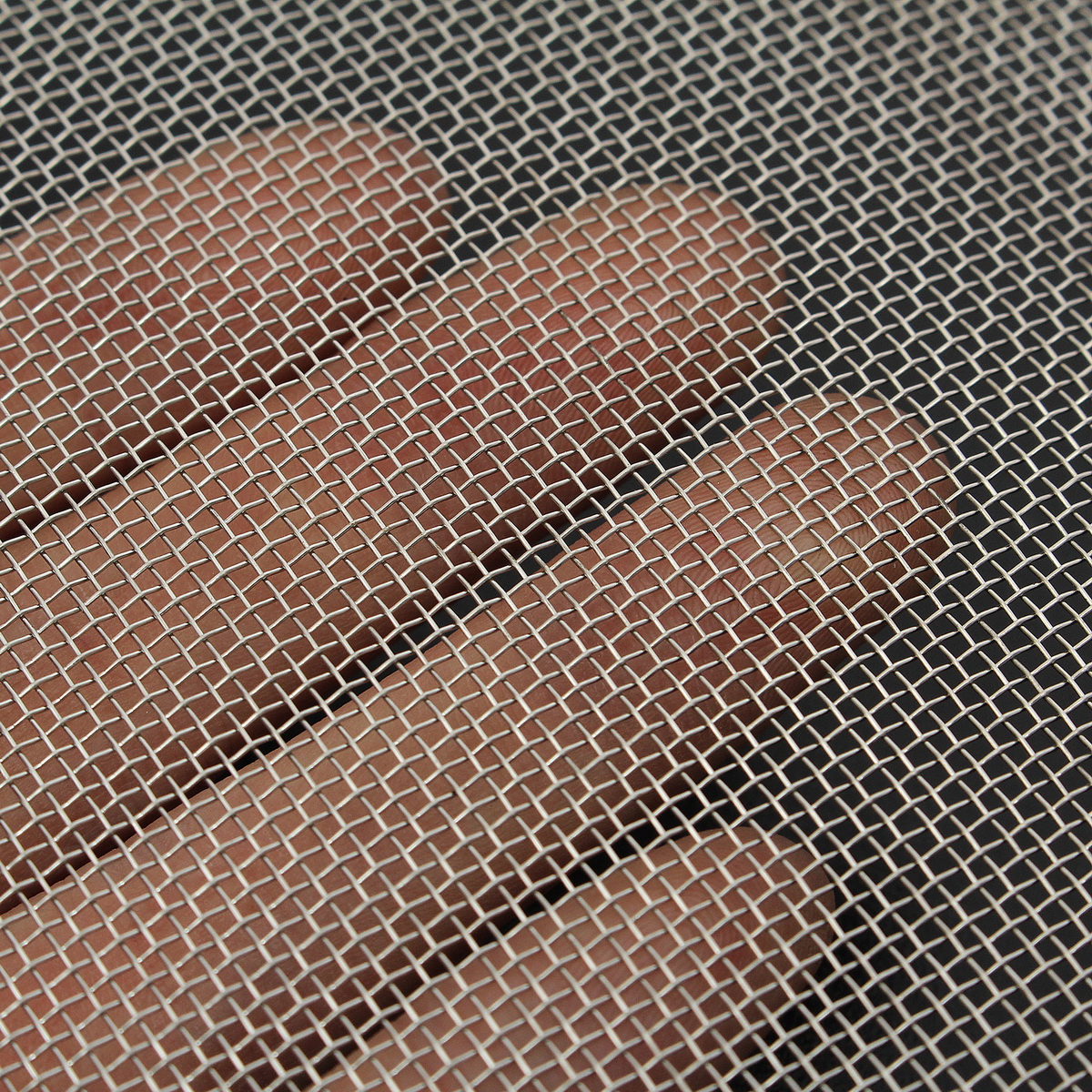

Steel matting, also known as steel grating or steel mesh, is a versatile and durable material widely used in various industries. Composed of a series of interconnected bars or wires, steel matting provides a robust surface that allows for both strength and airflow. Its applications range from construction and industrial use to drainage solutions and decorative design, making it an essential component in modern infrastructure.

Introduction to Steel Matting

Steel matting consists of welded or forged steel bars arranged in a grid-like pattern, designed to bear loads while allowing for the passage of light, air, and water. The production of steel matting typically involves high-strength steel, ensuring longevity and resilience even in harsh environments. The mesh can be treated with coatings, such as galvanization or powder coating, to enhance its resistance to corrosion and wear, further extending its lifespan.

Applications in Various Industries

One of the primary applications of steel matting is in the construction industry. It is often used as flooring in factories, warehouses, and walkways, where a durable and slip-resistant surface is crucial. Steel matting also plays a significant role in safety, as it reduces the likelihood of accidents by providing excellent drainage, preventing water accumulation that could lead to slip hazards.

In the automotive and aerospace sectors, steel matting is utilized for both structural applications and as part of machinery platforms

. Its strength-to-weight ratio makes it an ideal choice for supporting heavy equipment while maintaining a lightweight profile. Additionally, it is frequently employed in the manufacturing of stair treads and access platforms, facilitating industrial processes while ensuring worker safety.steel matting

Another vital area of application is in the environmental sector, particularly in drainage systems. Steel matting is commonly used in trench covers and gratings for stormwater management. The open design allows for efficient water flow while providing a robust cover that can withstand heavy vehicular traffic. This capability is particularly important in urban areas, where effective drainage is necessary to prevent flooding and manage runoff.

Advantages of Steel Matting

One of the main advantages of using steel matting is its durability. Steel is inherently strong, and when manufactured correctly, steel matting can last for decades even in the most demanding conditions. Its resistance to impact, corrosion, and extreme weather conditions makes it suitable for outdoor applications.

Additionally, steel matting is customizable, available in various sizes, thicknesses, and surface finishes. This adaptability allows for its use in a wide range of settings, from industrial sites to artistic installations. Its aesthetic appeal can also be utilized in decorative applications, where steel matting can accentuate architectural features in both commercial and residential projects.

Moreover, steel matting is environmentally friendly. Being made from recyclable materials, it aligns with sustainability goals in construction and manufacturing. The longevity of steel matting also contributes to reduced waste, as it does not need frequent replacement or maintenance.

Conclusion

In conclusion, steel matting is an indispensable material with diverse applications across many industries. Its strength, durability, and adaptability make it an ideal choice for construction, safety, and environmental management. As industries continue to evolve and prioritize sustainability and safety, the role of steel matting will undoubtedly expand, solidifying its place as an essential component in modern infrastructure and design. Whether in industrial settings, environmental solutions, or decorative architecture, steel matting stands as a testament to the blend of functionality and aesthetic appeal in engineering.

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025