-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Dec . 10, 2024 15:27 Back to list

farm fencing wire galvanized factories

Exploring the World of Farm Fencing Galvanized Wire Factories

In the realm of agriculture, effective fencing is crucial for protecting livestock, crops, and property. Among the numerous options available, galvanized wire fencing stands out for its durability, strength, and resistance to corrosion. As farming practices continue to evolve, the demand for high-quality galvanized farm fencing wire has led to the establishment of specialized factories dedicated to producing this essential material.

The Importance of Farm Fencing

Farm fencing serves multiple purposes. It acts as a barrier to keep livestock secured within boundaries while preventing wildlife from encroaching on cultivated fields. Additionally, it delineates property lines, supports the organization of farming operations, and enhances the aesthetic appeal of agricultural lands. Given the varied requirements of farmers, it is essential for fencing materials to be resilient, reliable, and long-lasting.

What is Galvanized Wire?

Galvanized wire refers to steel wire that has been coated with a layer of zinc to prevent corrosion. This protective layer significantly extends the lifespan of the wire, making it an ideal choice for outdoor applications. The galvanization process typically involves either hot-dipping, where the steel is submerged in molten zinc, or electro-galvanizing, which uses an electrical current to deposit zinc onto the steel surface. The hot-dipping method is generally favored in agricultural settings due to its superior protective qualities.

The Role of Factories in Production

Galvanized wire factories play a critical role in the agricultural industry. These facilities are equipped with advanced machinery and technology that allow for efficient production of high-quality wire products. From the initial stages of steel processing to the final steps of coating and quality control, every aspect of galvanized wire manufacturing is meticulously monitored to ensure optimal performance.

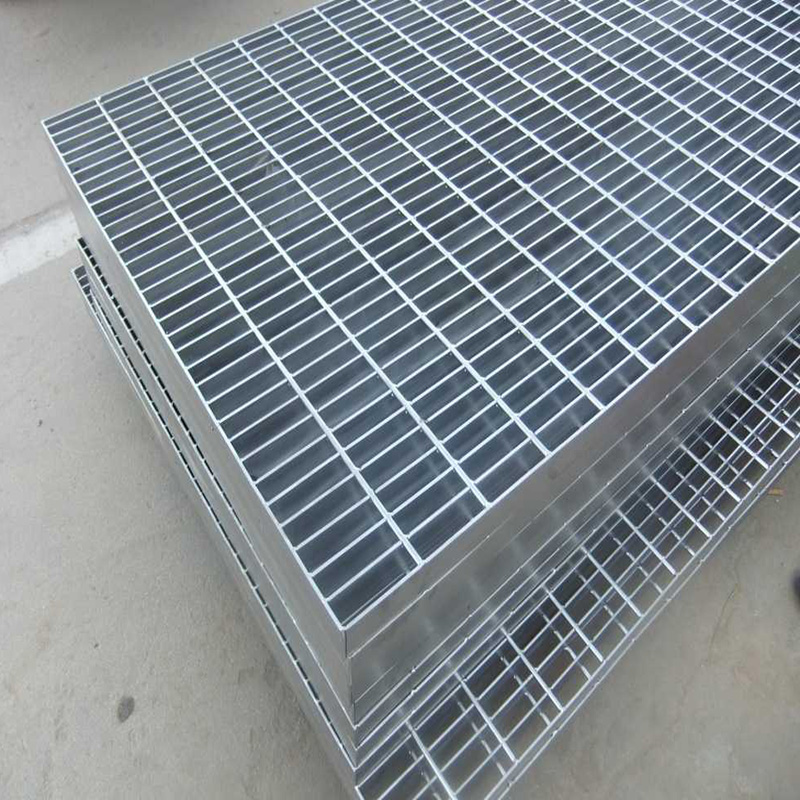

farm fencing wire galvanized factories

1. Raw Material Sourcing The production of galvanized wire begins with the selection of suitable steel. High-quality steel is critical for ensuring the strength and flexibility of the final product. Factories often establish partnerships with reputable steel suppliers and utilize state-of-the-art equipment to process raw steel into the desired wire gauge.

2. Wire Drawing The next step involves drawing the steel into wire form. This process requires precision machinery that gradually reduces the diameter of the steel while enhancing its tensile strength.

3. Galvanization Process Once the wire is drawn to the appropriate gauge, it undergoes galvanization. This process can vary based on factory capabilities, but it generally involves immersion in a zinc bath (hot-dipping) or passing through an electroplating system (electro-galvanizing). Factories often invest in modern galvanization lines to improve efficiency and ensure uniform coating.

4. Quality Control Quality assurance is paramount in galvanized wire production. Factories implement rigorous testing protocols to assess the wire's strength, flexibility, and corrosion resistance. This ensures that the final product meets or exceeds industry standards, providing farmers with trustworthy fencing solutions.

Applications of Galvanized Wire Fencing

Galvanized wire fencing is versatile and finds application in multiple areas of farming. It can be used for livestock enclosures, crop protection, garden fencing, and even as part of mesh fencing systems. The strength and durability of galvanized wire make it ideal for handling the demands of various agricultural environments, from flat pastures to rugged terrains.

Conclusion

The agricultural sector relies heavily on effective fencing solutions, and galvanized wire fencing has emerged as a premier choice among farmers. The factories dedicated to producing this essential material ensure that high standards are maintained throughout the manufacturing process, resulting in wire that is both robust and resilient. As farming practices evolve, the significance of galvanized wire fencing—and the factories that create it—will only continue to grow, further solidifying its role in sustainable agricultural practices. Whether for securing livestock, protecting crops, or defining property lines, farmers can trust that galvanized wire fencing will provide a reliable and long-lasting solution.

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025