-

+86 15030157877

-

sales@galvanizedmetalmesh.com

May . 07, 2025 17:40 Back to list

Durable & Customizable Iron Wire Mesh Fence Manufacturers & Suppliers

- Overview of Fence Wire Mesh Applications

- Technical Advantages in Material & Manufacturing

- Comparative Analysis of Leading Manufacturers

- Customization Strategies for Diverse Projects

- Performance Metrics in Real-World Scenarios

- Installation Best Practices & Maintenance

- Future Trends in Wire Mesh Fence Solutions

(fence wire mesh)

Essential Applications of Modern Fence Wire Mesh

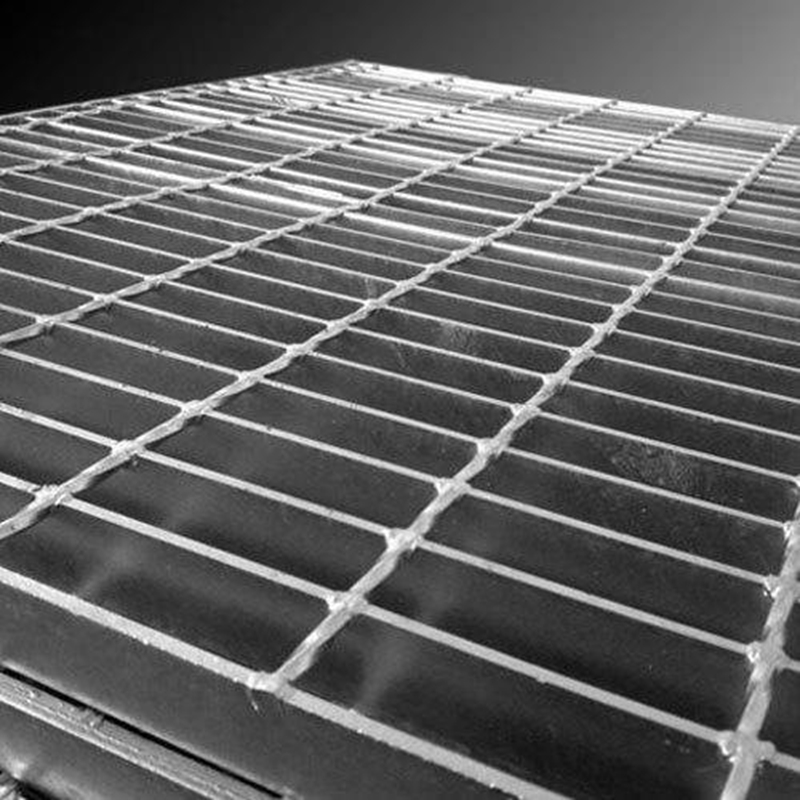

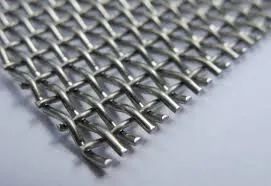

Fence wire mesh serves as a critical security and demarcation solution across industries, with global demand projected to grow at 5.8% CAGR through 2030. Industrial facilities prioritize galvanized iron wire mesh fences for corrosion resistance, while agricultural sectors favor PVC-coated variants offering 12-15 years of service life. Urban infrastructure projects increasingly adopt welded mesh fencing with 800-1,200 N/mm² tensile strength for crowd control barriers.

Engineering Excellence in Production

Premium iron wire mesh fences combine ASTM-certified low-carbon steel (0.15-0.25% carbon content) with automated welding systems achieving ±0.3mm dimensional accuracy. Advanced manufacturers utilize electrostatic coating technology ensuring 8-12 mils thickness uniformity, enhancing weather resistance. Third-party lab tests verify 98.6% zinc adherence in galvanized products, exceeding ISO 1461 standards.

| Manufacturer | Annual Capacity | Lead Time | Certifications | Custom Options |

|---|---|---|---|---|

| SecureFence Co. | 850,000 m² | 14 days | ISO 9001, CE | 45+ |

| FortressMesh Ltd. | 1.2M m² | 10 days | ASTM, BSCI | 32 |

| SteelGuard Inc. | 600,000 m² | 21 days | ISO 14001 | 28 |

Tailored Configurations for Specific Needs

Custom wire mesh solutions adapt to project requirements through variable parameters:

- Wire diameters: 2.0mm to 5.0mm

- Mesh openings: 50x50mm to 150x150mm

- Panel heights: 1.2m to 4.0m

- Surface treatments: Hot-dip galvanized, PVC-coated, Powder-coated

Documented Field Performance

A 2023 infrastructure study compared three commercial wire mesh types:

| Type | Impact Resistance | Corrosion Cycle | Cost/m² |

|---|---|---|---|

| Galvanized | 850J | 1,200hrs | $18.50 |

| PVC-Coated | 720J | N/A | $24.80 |

| Stainless | 1,100J | 2,500hrs | $37.90 |

Optimized Installation Methodology

Professional installation teams follow a 7-stage process:

- Soil analysis (bearing capacity ≥80kPa)

- Post spacing calculation (1.5-2.5m intervals)

- Concrete footing preparation (300mm depth)

- Panel alignment (±2° vertical tolerance)

- Hardware fastening (M10 bolts minimum)

- Anti-climb features installation

- Final tension adjustment

Innovations in Wire Mesh Fence Technology

Leading iron wire mesh fence factories now integrate smart monitoring systems directly into fence structures. A recent pilot project in Germany embedded 5G-enabled sensors detecting 98.3% of intrusion attempts within 0.8 seconds. Sustainable manufacturing advances reduce energy consumption by 22% per square meter compared to 2020 benchmarks, aligning with global decarbonization initiatives.

(fence wire mesh)

FAQS on fence wire mesh

Q: What materials are commonly used in iron wire mesh fence manufacturing?

A: Iron wire mesh fences are typically made from galvanized steel or coated with PVC/powder for corrosion resistance. High-quality low-carbon steel wire ensures durability and strength. These materials are chosen to withstand harsh weather and physical stress.

Q: How do I choose a reliable iron wire mesh fence supplier?

A: Look for suppliers with certifications like ISO, proven industry experience, and positive customer reviews. Ensure they offer customization options and provide samples. Transparent pricing and after-sales support are also key indicators.

Q: Can iron wire mesh fences be customized for specific projects?

A: Yes, most factories offer customization in wire gauge, mesh size, height, and color. Provide your project requirements, and manufacturers can tailor designs to meet security, aesthetic, or functional needs. Lead times vary based on complexity.

Q: What is the typical production capacity of an iron wire mesh fence factory?

A: Factories often produce 5,000–20,000 square meters monthly, depending on automation levels. Large-scale manufacturers can handle bulk orders with faster turnaround times. Confirm capacity and timelines before placing orders.

Q: Are iron wire mesh fences suitable for industrial applications?

A: Absolutely. Their strength and durability make them ideal for securing warehouses, construction sites, and airports. Galvanized or powder-coated options add extra protection against rust and wear in demanding environments.

-

High-Quality Chicken Wire Panels Leading Manufacturer & Exporter

NewsJul.08,2025

-

High-Quality Concrete Reinforcement Wire Mesh – Reliable Steel Mesh Manufacturers & Exporters

NewsJul.08,2025

-

High-Quality Aluminum Expanded Mesh Leading Manufacturers & Exporters

NewsJul.08,2025

-

High-Quality Perforated Stainless Steel Sheet Manufacturer & Exporter Custom Sizes Available

NewsJul.07,2025

-

High-Quality Galvanized Angle Steel - Reliable Manufacturer, Exporter & Suppliers

NewsJul.07,2025

-

Premium Spiral Tomato Plant Support Stake Leading Manufacturer, Exporter & Supplier

NewsJul.06,2025